In today's volatile market, supply chain efficiency is more than a competitive edge; it's a critical driver of profitability and resilience. Yet, many organizations overlook significant opportunities for savings, leaving money on the table through inefficient processes, excess inventory, and suboptimal logistics. These hidden costs erode margins and hinder growth, making a proactive approach to cost management essential for survival and success.

This guide moves beyond generic advice to provide a deep dive into 10 proven supply chain cost reduction strategies. Each strategy is broken down into actionable steps, supported by real-world examples, and tailored for mid-market and enterprise operations. We will explore how to leverage everything from AI-driven automation and strategic sourcing to not only cut expenses but also build a more agile, responsive, and robust supply chain.

You will learn how to implement practical tactics, identify key performance indicators for success, and avoid common pitfalls that can derail even the best-laid plans. We'll examine specific approaches like vendor-managed inventory, nearshoring, and advanced demand forecasting to illustrate how targeted improvements can yield substantial returns. Prepare to transform your operational challenges into tangible financial opportunities. This article provides the blueprint for creating a leaner, more cost-effective operation ready for the demands of 2025 and beyond.

1. Supplier Consolidation and Strategic Sourcing

Supplier consolidation is a strategic sourcing approach focused on reducing the total number of vendors a company buys from. Instead of spreading purchases across a wide array of suppliers, this strategy concentrates spending with a smaller group of high-performing, strategic partners. This intentional reduction leverages economies of scale, significantly boosts negotiating power, and simplifies supplier relationship management.

By channeling higher volumes to fewer vendors, companies can command better pricing, more favorable payment terms, and priority service. This tactic is one of the most effective supply chain cost reduction strategies because it directly cuts procurement costs while also reducing the administrative overhead associated with managing numerous accounts, contracts, and invoices. A prime example is Walmart's long-standing strategy of working closely with a consolidated supplier base to achieve its "Everyday Low Prices" promise.

Key Implementation Steps

- Supplier Base Analysis: Begin by segmenting your entire supplier list by spend, criticality, and performance. Identify redundant suppliers providing similar goods or services.

- Strategic Partner Selection: Conduct thorough audits of top-performing suppliers. Evaluate their financial stability, quality control processes, and capacity to handle increased volume.

- Negotiate Long-Term Agreements: Approach selected partners to negotiate multi-year contracts that include volume-based discounts, clear service-level agreements (SLAs), and performance metrics.

- Streamline Onboarding and Management: Digitize and automate the procurement process for these key partners. Using technology for purchase orders, invoicing, and performance tracking minimizes manual work. For more insights on this, explore how you can leverage automation in procurement.

Key Insight: The goal isn't just to cut suppliers but to build deeper, collaborative partnerships. A strategic supplier can become an extension of your own team, offering innovation and contributing to continuous improvement efforts, turning a simple cost-cutting move into a long-term competitive advantage.

2. Just-In-Time (JIT) Manufacturing

Just-In-Time (JIT) is a lean manufacturing methodology where materials are ordered from suppliers and produced into goods based on actual, immediate demand, rather than on forecasts. This approach synchronizes the production schedule with the supply chain, ensuring that inventory arrives precisely when it's needed for manufacturing. The core goal is to eliminate waste by minimizing inventory holding costs, which include storage space, insurance, and the risk of obsolescence.

This strategy is one of the most powerful supply chain cost reduction strategies because it directly attacks the capital tied up in excess stock. By reducing warehouse needs and improving cash flow, companies can operate more efficiently and respond faster to market changes. Toyota famously pioneered this system to create a highly efficient, waste-free production line, and Dell applied it to its direct-to-consumer model, building computers only after a customer placed an order.

Key Implementation Steps

- Strengthen Supplier Partnerships: JIT is impossible without highly reliable and responsive suppliers. Work with vendors who can guarantee consistent quality and on-time delivery, often requiring them to be located in close geographic proximity.

- Implement Advanced Demand Forecasting: Utilize AI-powered forecasting tools to predict customer demand with high accuracy. This data is critical for signaling to suppliers exactly what is needed and when, preventing both stockouts and overproduction.

- Invest in Supply Chain Visibility: Deploy IoT sensors and real-time tracking systems to monitor inventory levels and material movement from the supplier to the factory floor. This visibility allows for precise coordination and rapid response to disruptions.

- Redesign Production Workflows: Reorganize the factory layout and processes to support a continuous, smooth flow of materials. For a deeper dive into streamlining inventory and reducing waste, explore the core principles of Just-In-Time (JIT) inventory principles.

Key Insight: JIT is more than an inventory tactic; it's a manufacturing philosophy that exposes inefficiencies. While it drastically cuts holding costs, its success hinges entirely on the predictability and reliability of your entire supply chain, from supplier performance to production scheduling.

3. Process Optimization and Lean Manufacturing

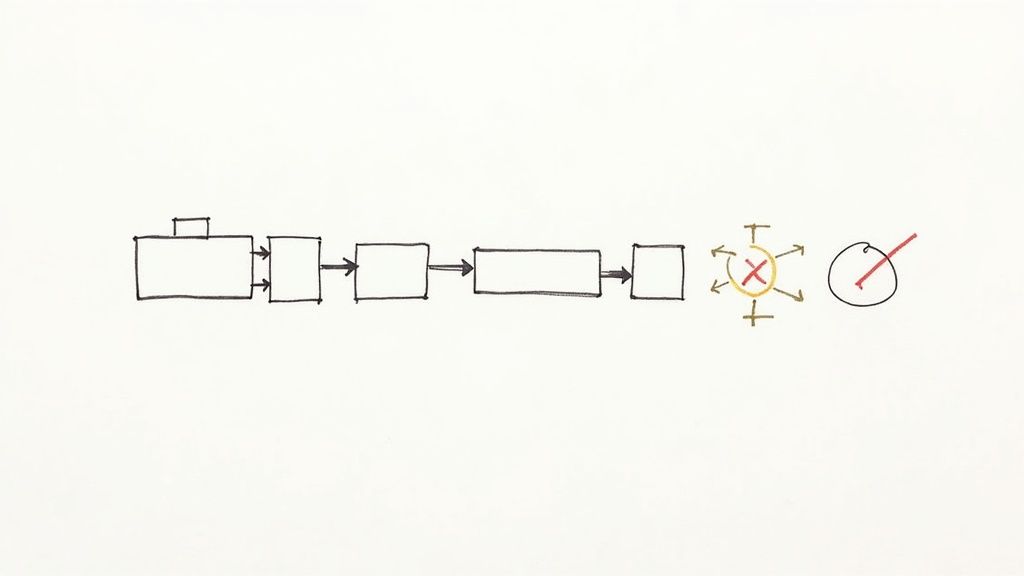

Process optimization involves systematically identifying and eliminating waste from manufacturing and supply chain operations using Lean principles. This approach focuses on maximizing customer value by minimizing non-value-added activities, such as overproduction, waiting times, unnecessary transport, and defects. By adopting a lean mindset, organizations can create more efficient, responsive, and cost-effective supply chains.

This is a cornerstone among supply chain cost reduction strategies because it targets the root causes of inefficiency rather than just the symptoms. By streamlining workflows and removing bottlenecks, companies reduce operational expenses, improve throughput, and enhance product quality, leading to lower warranty claims and rework costs. The Toyota Production System (TPS) is the quintessential example, demonstrating how a relentless focus on waste elimination can lead to world-class efficiency and market leadership.

Key Implementation Steps

- Conduct Value Stream Mapping (VSM): Begin by mapping your current state process from raw materials to final delivery. This visual tool helps identify every step, highlighting areas of waste and opportunities for improvement.

- Implement the 5S Methodology: Organize the workplace by Sorting, Setting in order, Shining, Standardizing, and Sustaining. A clean and organized environment reduces wasted time searching for tools or materials and improves safety.

- Empower Teams with Kaizen: Foster a culture of continuous improvement by holding Kaizen events. These are short-term, focused projects where cross-functional teams work to solve specific process problems and implement immediate changes.

- Adopt a Pull System: Move from a "push" (forecast-based) to a "pull" (demand-based) system using methods like Kanban. This minimizes overproduction, reduces inventory carrying costs, and improves responsiveness to actual customer demand. For a deeper dive, see these additional methods to improve supply chain efficiency.

Key Insight: True process optimization is not a one-time project but a cultural shift. It requires empowering every employee to see and eliminate waste in their daily work, transforming the entire organization into a highly efficient, value-driven system that consistently reduces operational costs.

4. Nearshoring and Localized Supply Networks

Nearshoring is the practice of relocating manufacturing and sourcing operations to countries that are geographically closer to the end market. Instead of relying on distant offshore locations, this strategy brings production nearer to home, drastically cutting transportation costs, shortening lead times, and reducing geopolitical risks. It creates a more responsive and agile supply chain by minimizing the complexities associated with long-distance logistics.

This approach is a powerful supply chain cost reduction strategy because it lowers freight expenses and buffer inventory requirements, while also enhancing supply chain visibility. By reducing transit times from weeks to days, companies can react faster to demand shifts and disruptions. For instance, many U.S. automotive and electronics firms have shifted production from Asia to Mexico to better serve the North American market, benefiting from lower shipping costs and quicker turnaround times.

Key Implementation Steps

- Conduct a Total Cost of Ownership (TCO) Analysis: Evaluate beyond just labor costs. Factor in logistics, tariffs, inventory carrying costs, and the risks of long supply lines.

- Assess Regional Supplier Capabilities: Thoroughly vet potential suppliers in the nearshore region for their quality standards, production capacity, technological sophistication, and financial stability.

- Evaluate Infrastructure and Logistics: Analyze the quality of the target country’s ports, roads, and customs processes. A strong logistics infrastructure is critical for the strategy's success.

- Develop Local Partnerships: Build strong relationships with local suppliers and logistics providers. These partnerships are essential for navigating regional business practices and regulations smoothly.

Key Insight: Nearshoring is not merely a cost-cutting measure; it's a strategic move toward resilience. A localized supply network provides a natural hedge against global disruptions, currency fluctuations, and trade volatility, transforming your supply chain from a cost center into a durable competitive advantage.

5. Demand Planning and Forecasting Technology

Demand planning and forecasting technology leverages advanced analytics, artificial intelligence (AI), and machine learning to predict customer demand with greater accuracy. Instead of relying solely on historical sales data, these systems analyze a wide range of variables, including market trends, seasonality, promotional activities, and even external factors like weather or economic indicators. This data-driven approach is a cornerstone of modern supply chain cost reduction strategies because it directly mitigates the two most expensive inventory problems: overstocking and stockouts.

Accurate forecasts allow companies to optimize inventory levels, reducing carrying costs, warehousing expenses, and the risk of obsolescence associated with excess stock. At the same time, they prevent lost sales and customer dissatisfaction caused by stockouts. For instance, Amazon's sophisticated forecasting algorithms enable it to position products in fulfillment centers before customers even place their orders, drastically reducing shipping times and costs while ensuring product availability.

Key Implementation Steps

- Data Aggregation and Cleansing: Start by centralizing and cleaning all relevant data sources. This includes historical sales, marketing campaign data, social media trends, and any third-party market data.

- Implement an Advanced Analytics Platform: Select and deploy a forecasting tool that utilizes AI and machine learning. These platforms can identify complex patterns that are invisible to traditional analysis.

- Integrate Cross-Functional Inputs: Foster collaboration between supply chain, sales, and marketing teams. Their qualitative insights into upcoming promotions or market shifts provide crucial context for the quantitative data.

- Establish a Feedback Loop: Continuously measure forecast accuracy against actual sales and use the results to refine the algorithms. For more advanced methods in predicting future demand and optimizing inventory, exploring various time series forecasting techniques can significantly enhance your planning accuracy.

Key Insight: The value of modern forecasting technology isn't just a more accurate number; it's the ability to run simulations and "what-if" scenarios. This allows supply chain leaders to proactively plan for disruptions and market changes, transforming forecasting from a reactive report into a strategic decision-making tool.

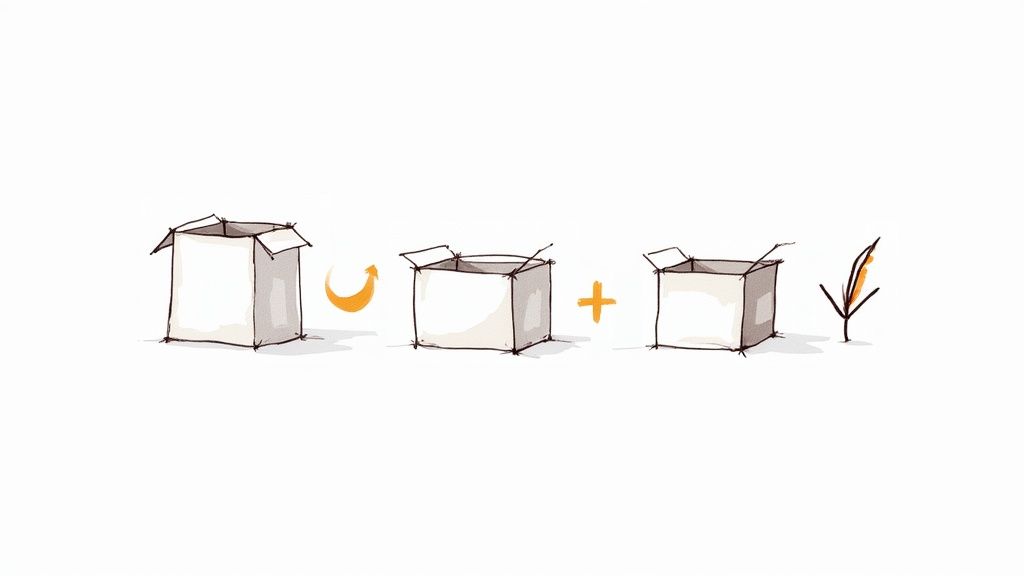

6. Reverse Logistics and Circular Supply Chain

Reverse logistics is the process of managing the return flow of products from consumers back to the manufacturer or retailer. It goes beyond simple returns by creating value from used, damaged, or obsolete goods through repair, refurbishment, reselling, or recycling. This approach transforms a traditional cost center into a potential revenue stream and is a cornerstone of a circular supply chain, which aims to eliminate waste and keep materials in use.

Implementing a robust reverse logistics program is a powerful supply chain cost reduction strategy because it minimizes waste disposal fees, recovers the value of returned assets, and can generate new revenue channels. It also meets growing consumer demand for sustainable practices. For instance, Patagonia's Worn Wear program accepts used gear for repair and resale, reducing waste while reinforcing its brand commitment to sustainability and quality.

Key Implementation Steps

- Design for Disassembly: Collaborate with product development teams to design products that can be easily taken apart, repaired, or recycled. This significantly lowers the cost of processing returns.

- Create Convenient Return Processes: Make it simple for customers to return products. Clear instructions, accessible drop-off points, and prepaid shipping labels can increase return rates for valuable items.

- Invest in Sorting and Grading Technology: Use automated systems to quickly sort returned items based on their condition. This helps triage products for resale, refurbishment, or recycling, maximizing value recovery.

- Develop Strategic Partnerships: Partner with certified recycling facilities, secondary market resellers, or charitable organizations to efficiently manage the end-of-life for products that cannot be resold. AI can be instrumental in optimizing these complex networks. For more on this, see how companies are using AI for supply chain optimization.

Key Insight: A well-executed reverse logistics strategy does more than just cut costs; it builds customer loyalty and enhances brand reputation. By demonstrating a commitment to sustainability and product lifecycle management, companies can attract environmentally conscious consumers and turn a potential operational headache into a competitive advantage.

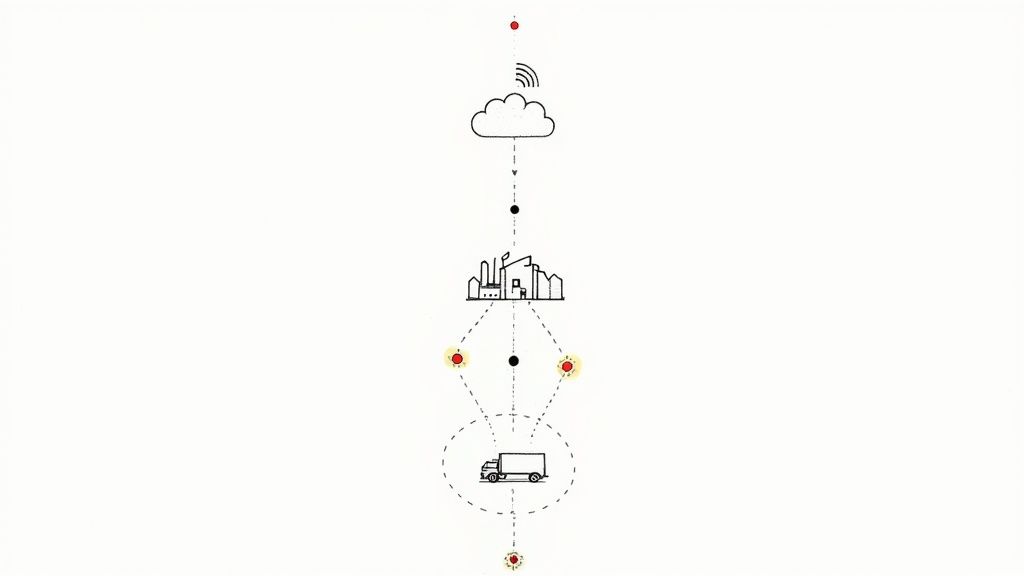

7. Supply Chain Digitalization and IoT Integration

Supply chain digitalization involves integrating advanced digital technologies like the Internet of Things (IoT), blockchain, and cloud-based platforms to create a fully transparent, connected, and automated operational ecosystem. This strategy transforms traditional, siloed supply chain functions into a dynamic, data-driven network. It enables real-time asset tracking, predictive maintenance, and process automation, directly addressing inefficiencies that lead to higher costs.

By embedding IoT sensors in shipments, warehouses, and vehicles, companies gain unprecedented end-to-end visibility. This is a powerful supply chain cost reduction strategy because it minimizes losses from theft, spoilage, or damage while optimizing routes and inventory levels based on live data. For instance, Maersk’s TradeLens platform uses blockchain to securely digitize global trade documentation, drastically reducing administrative delays and costs for all parties involved.

Key Implementation Steps

- Identify High-Impact Areas: Begin by pinpointing the parts of your supply chain with the most significant inefficiencies or lack of visibility, such as last-mile delivery or cold chain logistics. Start with a pilot project in one of these areas to prove ROI.

- Select the Right Technology Stack: Evaluate IoT, blockchain, and AI platforms based on their ability to integrate with your existing ERP and WMS systems. Prioritize solutions that offer scalability and robust data security.

- Establish Data Governance and Security: Create clear protocols for data ownership, access, and security to protect sensitive information and ensure regulatory compliance.

- Invest in Training and Change Management: Equip your team with the skills to use new digital tools effectively. Communicate the benefits of digitalization to foster adoption and ensure a smooth transition from legacy processes.

Key Insight: Digitalization is not just about adopting new technology; it's about creating a single source of truth across your entire supply network. This unified data stream empowers proactive decision-making, allowing you to anticipate disruptions and optimize operations before costs escalate, turning your supply chain into a significant competitive advantage.

8. Packaging Optimization and Lightweighting

Packaging optimization involves redesigning product packaging to use less material, reduce overall weight, and minimize dimensions without compromising product integrity. This strategy directly targets transportation costs, which are often calculated based on dimensional weight (DIM weight) and actual weight. By making packages smaller and lighter, companies can fit more units into a single shipment, significantly cutting fuel and freight expenses.

This approach is one of the most impactful supply chain cost reduction strategies because it creates a ripple effect of savings. Lighter packages are cheaper to ship, optimized dimensions reduce warehousing space requirements, and using less material lowers direct procurement costs. Amazon’s Frustration-Free Packaging initiative is a leading example, where products are shipped in their own containers, eliminating the need for an additional shipping box and reducing waste and costs simultaneously.

Key Implementation Steps

- Conduct a Packaging Audit: Analyze current packaging for excess material, unnecessary layers, and empty space (air). Use damage analysis data to understand if current packaging is over-engineered for the protection it provides.

- Leverage Design Software: Utilize packaging design software to model and simulate new, more efficient designs. This technology can help identify material reductions and structural improvements before creating physical prototypes.

- Test New Designs Rigorously: Before a full rollout, subject prototype packaging to comprehensive transit tests that simulate real-world shipping conditions. This ensures the new design adequately protects the product and prevents an increase in damage-related costs.

- Collaborate with Logistics Partners: Work with your freight carriers to understand their pricing models. Aligning your packaging redesign with their dimensional weight rules ensures you capture the maximum possible cost savings.

Key Insight: Packaging optimization is not just a cost-cutting measure; it is a powerful sustainability initiative. Reducing material use and shipping lighter loads lowers your carbon footprint, enhances brand reputation, and meets growing consumer demand for environmentally responsible practices.

9. Vendor-Managed Inventory (VMI) and Consignment Programs

Vendor-Managed Inventory (VMI) is a collaborative supply chain model where the supplier takes responsibility for maintaining a customer's inventory levels. Instead of the buyer managing purchase orders, the supplier monitors stock levels directly, often using shared data, and replenishes products as needed. This proactive approach shifts carrying costs and administrative burdens from the buyer to the supplier, creating one of the most symbiotic supply chain cost reduction strategies.

By transferring inventory ownership until the point of use or sale (in a consignment model), companies dramatically reduce capital tied up in stock and minimize the risk of obsolescence. This deepens the supplier-buyer relationship, improving product availability and reducing the likelihood of stockouts. For instance, Cisco Systems utilizes VMI to give its suppliers visibility into real-time demand, allowing them to manage component inventory efficiently and ensure a more resilient production line.

Key Implementation Steps

- Select Capable VMI Partners: Identify and vet suppliers with a proven track record of reliability, technological capability, and financial stability. A VMI partnership is a significant commitment that requires trust.

- Establish Clear Service-Level Agreements (SLAs): Define agreed-upon minimum and maximum inventory levels, lead times, fill rates, and performance metrics. These parameters must be explicit to prevent disputes.

- Implement Real-Time Data Sharing: Utilize EDI, APIs, or a shared technology platform to give suppliers direct visibility into your inventory data and consumption rates. Accurate, timely data is the foundation of a successful VMI program.

- Define Ownership and Payment Terms: Clearly outline when ownership of the inventory transfers from the supplier to you. In a consignment model, this typically occurs at the point of consumption, not delivery.

Key Insight: VMI is more than just outsourcing inventory management; it's a strategic alignment of incentives. When suppliers are responsible for stock levels, their goal shifts from simply selling more product to ensuring the right product is available at the right time, directly aligning their success with your operational efficiency and customer satisfaction.

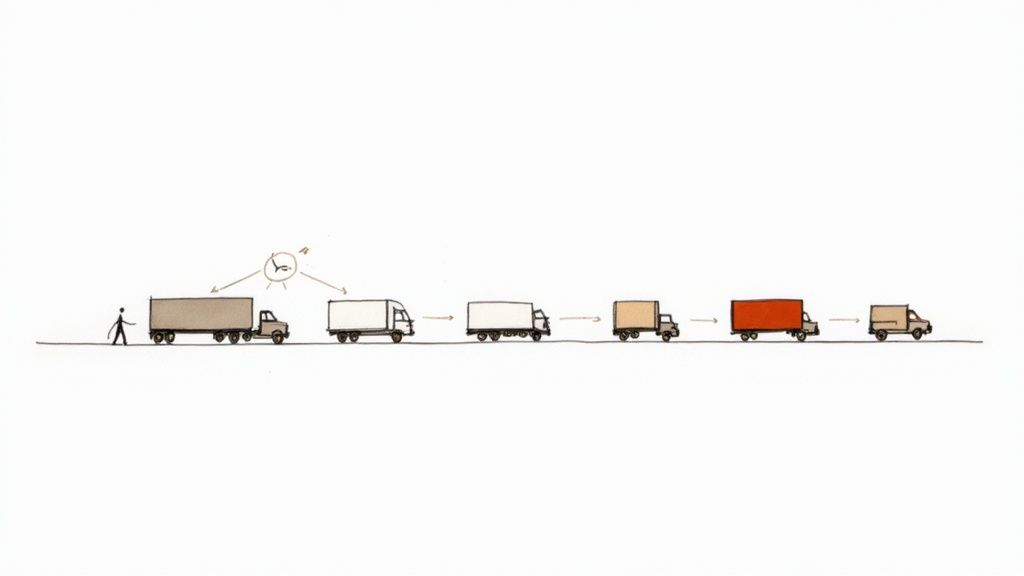

10. Freight and Transportation Optimization

Freight and transportation optimization is a core supply chain cost reduction strategy focused on systematically minimizing the expense of moving goods. This involves more than just finding the cheapest carrier; it's about intelligently planning routes, selecting the most efficient transport modes, and consolidating shipments to maximize capacity. By leveraging advanced analytics and technology, companies can dramatically reduce fuel consumption, labor costs, and transit times.

This approach directly attacks one of the largest variable costs in any supply chain: logistics. Effective optimization turns transportation from a simple operational cost center into a source of competitive advantage. A classic example is UPS's On-Road Integrated Optimization and Navigation (ORION) system, which uses complex algorithms to determine the most efficient delivery route for every driver, saving millions of gallons of fuel and miles driven annually.

Key Implementation Steps

- Implement a Transportation Management System (TMS): A TMS is the technological backbone for optimization. It centralizes carrier management, automates load tendering, provides real-time visibility, and enables sophisticated route planning and freight consolidation.

- Consolidate Shipments Strategically: Analyze order patterns to identify opportunities for load consolidation. Combine smaller Less-Than-Truckload (LTL) shipments into full truckloads (FTL) to achieve better per-unit shipping rates and reduce handling.

- Leverage Multi-Modal Transportation: Don't rely on a single mode of transport. Analyze cost, speed, and reliability trade-offs between truck, rail, sea, and air. A multi-modal strategy can significantly lower costs for less time-sensitive legs of a journey.

- Negotiate Carrier Contracts: Use data from your TMS to negotiate volume-based discounts and performance-based contracts with carriers. Centralizing your freight spend gives you greater leverage and helps build strategic carrier partnerships.

Key Insight: True transportation optimization is dynamic, not static. Continuous analysis of key metrics like cost-per-mile, on-time delivery rates, and fuel surcharge impacts is essential. Market conditions, fuel prices, and carrier capacity change constantly, and your strategy must be agile enough to adapt.

Supply Chain Cost Reduction: 10-Strategy Comparison

| Strategy | Implementation complexity | Resource requirements | Expected outcomes | Ideal use cases | Key advantages |

|---|---|---|---|---|---|

| Supplier Consolidation and Strategic Sourcing | Moderate–High (negotiations, audits) | Procurement team time, legal, supplier audits | Lower unit costs, simplified supplier management, increased dependency risk | Large buyers seeking volume leverage and simpler supplier base | Lower per‑unit costs, streamlined contracts, improved supplier collaboration |

| Just‑In‑Time (JIT) Manufacturing | High (process redesign, tight coordination) | Reliable suppliers, advanced forecasting, logistics capability | Significantly lower inventory carrying costs, higher turnover, fragile to disruption | Stable demand products, lean production environments | Reduced inventory and waste, improved cash flow, faster cycles |

| Process Optimization and Lean Manufacturing | High (organizational change, training) | Training, CI teams, value‑stream mapping tools | Reduced operational waste, improved quality and productivity | Manufacturing and operations aiming for continuous improvement | Broad cost reduction, quality gains, faster production |

| Nearshoring and Localized Supply Networks | Moderate–High (relocation, supplier setup) | Facility investment, regional supplier sourcing, logistics planning | Shorter lead times, lower transport costs, improved resilience | Time‑sensitive markets, firms prioritizing responsiveness and risk reduction | Faster delivery, better oversight, reduced geopolitical risk |

| Demand Planning and Forecasting Technology | High (data integration, model deployment) | Analytics platforms, data scientists, clean data pipelines | Improved forecast accuracy, fewer stockouts, lower inventory costs | Complex demand patterns, data‑rich retailers and manufacturers | Data‑driven decisions, inventory optimization, scenario planning |

| Reverse Logistics and Circular Supply Chain | High (reverse flows, compliance) | Sorting/refurbishment centers, logistics networks, partnerships | Material recovery, reduced disposal costs, added revenue streams | Durable goods, regulated products, sustainability‑focused firms | Revenue recovery, lower raw material needs, stronger ESG profile |

| Supply Chain Digitalization and IoT Integration | High (IT integration, security) | IoT sensors, cloud platforms, cybersecurity, technical staff | Real‑time visibility, fewer manual errors, faster incident response | Global/complex networks needing end‑to‑end visibility and automation | Enhanced visibility, automation, predictive maintenance, fraud reduction |

| Packaging Optimization and Lightweighting | Low–Moderate (design and testing) | Packaging design resources, testing, supplier coordination | Lower shipping costs, reduced material use, risk of damage if over‑optimized | High‑volume shippable goods, e‑commerce and retail distribution | Reduced freight and material costs, sustainability and handling gains |

| Vendor‑Managed Inventory (VMI) and Consignment Programs | Moderate–High (trust, systems integration) | Real‑time data sharing, SLAs, reliable supplier partnerships | Reduced buyer carrying costs, improved availability, supplier assumes stock risk | Stable SKUs, retail, healthcare, companies with strategic suppliers | Lower inventory costs for buyer, improved turnover, fewer stockouts |

| Freight and Transportation Optimization | Moderate (TMS, routing algorithms) | TMS, carrier contracts, route analytics, logistics expertise | Lower transportation costs, improved on‑time delivery, reduced emissions | Businesses with significant freight spend and complex routing needs | Fuel and cost savings, better asset utilization, faster deliveries |

From Strategy to Action: Building a Cost-Efficient Future

The journey toward a leaner, more cost-effective supply chain is not a destination but a continuous cycle of analysis, adaptation, and optimization. We've explored ten powerful supply chain cost reduction strategies, from the foundational principles of lean manufacturing and strategic sourcing to the cutting-edge applications of digitalization and demand forecasting technology. Each strategy offers a unique lever to pull, yet their true power is unlocked when they are viewed not as isolated tactics, but as interconnected components of a holistic, data-driven operational philosophy.

The core message is clear: sustainable cost reduction is a byproduct of operational excellence. It emerges from building stronger, more collaborative supplier relationships, eliminating waste at every stage of production, and harnessing technology to gain unprecedented visibility and control over your entire network. Moving from a reactive, fire-fighting mode to a proactive, predictive stance is the fundamental shift that separates market leaders from the rest.

Synthesizing the Strategies for Maximum Impact

While implementing any single strategy, such as packaging optimization or freight consolidation, can yield immediate savings, the most profound transformations occur when these approaches are integrated. Consider how these strategies build upon one another:

- Technology as the Foundation: Advanced demand planning and forecasting (Strategy 5) provide the data needed to successfully implement Just-In-Time manufacturing (Strategy 2) or Vendor-Managed Inventory programs (Strategy 9). Similarly, IoT integration (Strategy 7) provides the real-time visibility required to optimize transportation routes and manage reverse logistics effectively.

- Partnerships as the Amplifier: Strategic sourcing and supplier consolidation (Strategy 1) are not just about negotiating lower prices. They are about building partnerships that enable deeper collaboration, such as VMI programs (Strategy 9), which reduce your inventory holding costs while giving suppliers better visibility into demand.

- Efficiency as the Goal: Process optimization and lean principles (Strategy 3) create the operational discipline needed to capitalize on other initiatives. A lean mindset helps identify waste that can be eliminated through better packaging (Strategy 8) or more efficient transportation (Strategy 10).

The key is to move beyond a siloed approach. An effective supply chain cost reduction strategy requires cross-functional collaboration. Your procurement, logistics, operations, and finance teams must work in concert, sharing data and aligning on objectives to drive meaningful, enterprise-wide change.

Your Actionable Path Forward

Translating these ideas into tangible results requires a structured approach. Start by benchmarking your current performance to identify the most significant cost drivers and areas of inefficiency. Don't try to boil the ocean; instead, prioritize one or two high-impact strategies that align with your immediate business goals.

For instance, if high inventory carrying costs are your biggest pain point, focus on improving demand forecasting and exploring a VMI pilot program. If soaring freight expenses are eroding your margins, a deep dive into transportation optimization and nearshoring could be your best first step.

Create a pilot project, define clear success metrics, and measure the results rigorously. Use the insights gained to build a business case for broader implementation. This iterative, data-backed methodology builds momentum and secures the buy-in necessary for long-term transformation. Ultimately, mastering these supply chain cost reduction strategies is about more than just trimming expenses; it's about building a resilient, agile, and competitive operation that can thrive in an unpredictable global market.

Ready to accelerate your cost-reduction initiatives with intelligent automation? Red Brick Labs specializes in building custom AI-powered workflows that automate complex tasks, from demand forecasting and inventory analysis to logistics coordination, driving efficiency directly into your bottom line. Discover how our tailored solutions can help you implement these strategies faster and with greater precision at Red Brick Labs.