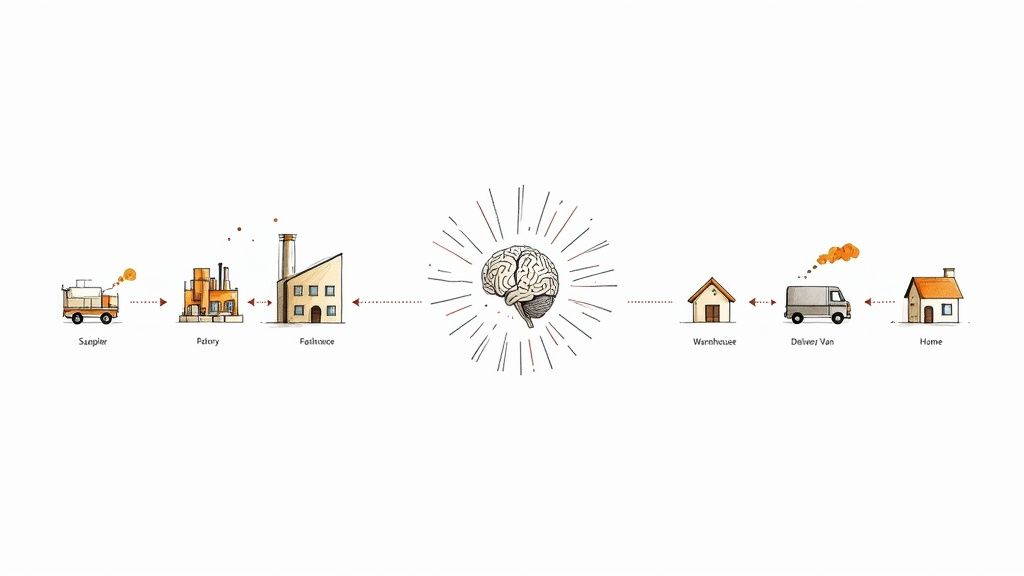

When you hear about artificial intelligence in supply chain optimization, it’s not just about fancy algorithms. It's about using smart technology, like machine learning, to dig into your data, predict what’s coming next, and make better decisions across the board—from logistics and inventory to demand planning.

This is a fundamental shift. Instead of constantly putting out fires, you’re using data to prevent them from starting in the first place. It’s how today's businesses are building more resilient operations and getting a serious leg up on the competition.

Why AI Is Reshaping Modern Supply Chains

Let's face it, the modern supply chain isn’t the clean, linear process it used to be. It’s a messy, tangled web of global suppliers, unpredictable consumer demand, and curveballs you never see coming. The old ways of managing it—relying on historical data and manual tweaks—just can't keep up anymore.

This is exactly where AI comes in to change the game.

Instead of just reacting when a shipment gets delayed, AI helps you see it coming. By crunching real-time data from countless sources—think IoT sensors on your trucks, weather forecasts, and even social media trends—AI models can flag potential problems long before they grind your operations to a halt.

Moving From Reactive to Predictive Operations

The biggest change AI for supply chain optimization brings is moving from a reactive "what just happened?" mindset to a predictive "what's about to happen?" one. This proactive approach unlocks some serious advantages.

- Anticipatory Demand Forecasting: Forget just looking at last year's sales. AI dives into complex variables to forecast customer demand with startling accuracy, saving you from both the cost of overstocking and the pain of missed sales.

- Dynamic Inventory Management: Smart algorithms constantly recalculate the perfect stock level for every single item, in every single warehouse. This minimizes carrying costs without ever running out of what your customers want.

- Intelligent Route Optimization: AI-powered logistics can adjust delivery routes on the fly based on live traffic, weather alerts, and changing delivery schedules. The result? Lower fuel costs and happier customers.

This isn't just about making small tweaks for a little more efficiency. It’s about building a supply chain that practically runs itself—a system that learns from new information, adapts to chaos, and gets smarter over time. Our guide on how to improve supply chain efficiency digs deeper into these core ideas.

The numbers tell a compelling story. The market for AI in supply chain management was around USD 9.94 billion in 2025, and it’s expected to explode to USD 157.6 billion by 2030. That kind of growth shows just how critical these solutions have become.

To see what this looks like in the real world, check out these 5 AI use cases for supply chain data integration.

Building Your Foundation for AI Success

Before a single algorithm gets fired up, we need to talk about the groundwork. I've seen too many AI for supply chain optimization projects fizzle out, and it's almost never because the model was wrong. It's because they skipped the foundational work.

This first phase isn't about fancy tech; it’s about having honest conversations about your goals and your data. Get this part right, and everything that follows becomes exponentially easier.

The journey starts by ditching vague goals like "improving efficiency" and getting surgically precise. Where are the biggest headaches in your operation right now? Is it chronic stockouts on a best-selling product line? Maybe it's the sky-high carrying costs at your West Coast distribution center. Or is it the maddeningly unpredictable delivery times that are costing you key accounts?

Zero in on those specific pain points. That’s how you find a pilot project that actually delivers a win.

For example, a CPG company I worked with noticed that 15% of its top products were out of stock during peak season. That’s not just a statistic—that’s lost revenue and unhappy customers. This became the perfect, focused problem for an AI-powered demand forecasting model.

Defining Your North Star Metrics

Once you’ve pinpointed the problem, you need to define what "winning" looks like. Vague ambitions don’t get you budget, and they certainly don’t prove value later on. This is where you establish crystal-clear Key Performance Indicators (KPIs) that tie directly back to the business. These KPIs are your project's north star.

Here are a few examples of KPIs that actually mean something:

- Inventory Reduction: Cut on-hand inventory for our slow-moving SKUs by 20% in the next six months.

- Forecast Accuracy: Boost our SKU-level demand forecast accuracy from 75% to 90% next quarter.

- On-Time Delivery: Lift our on-time, in-full (OTIF) delivery rate from 88% to 95% for our top 20 customers.

Success in AI isn't about the tech itself; it’s about moving a business metric. Your KPIs should tell a simple story: "We are using AI to achieve X, which will save us Y dollars or make Z customers happier."

Nailing these metrics down early gets everyone on the same page, from the data scientists building the models to the warehouse managers who will use the outputs. A core principle of how to implement AI in business is achieving this strategic alignment long before you write a single line of code.

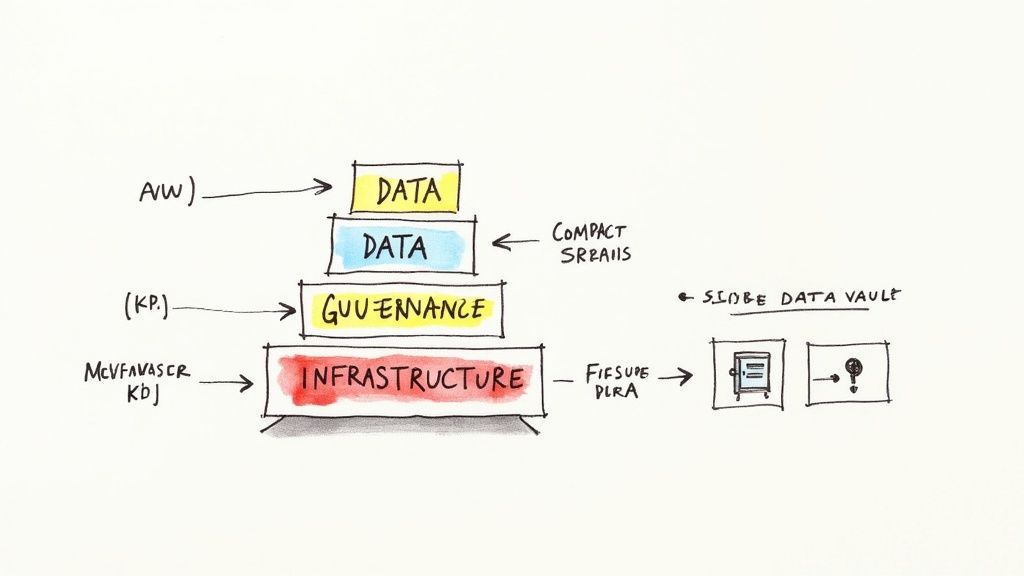

Achieving Data Readiness

Okay, you have a clear scope and solid KPIs. Now it's time to face the beast: your data. Your AI models will only ever be as smart as the data you feed them. For most companies, this is where the real work begins. The data is almost always scattered across siloed systems—ERPs, a Warehouse Management System (WMS), a separate Transportation Management System (TMS), and probably a dozen critical spreadsheets.

Breaking down these silos isn't optional. It means building a unified data pipeline to pull everything into one place, like a data lake or warehouse. A huge part of this is just getting clean data into the system in the first place, which is why automating data entry with AI is often a critical first step to fix broken manual processes.

Your data readiness checklist needs to hit three main pillars:

- Quality: Is the data clean? This means hunting down and fixing inconsistencies—like seeing three different product codes for the exact same item or finding entire days of missing sales figures.

- Completeness: Are there massive gaps in your history? An AI can't predict future demand if half of last year's sales data never made it into the system.

- Accessibility: Can your team actually get their hands on the data they need? If it takes two weeks and an act of Congress to get a data extract, your project is already dead in the water.

Establishing strong data governance from day one ensures these standards stick. This isn’t just about making your pilot project work; it's about building a reliable foundation for every AI initiative that comes after. Getting this right is what separates a flashy proof-of-concept from a tool that genuinely transforms your operations.

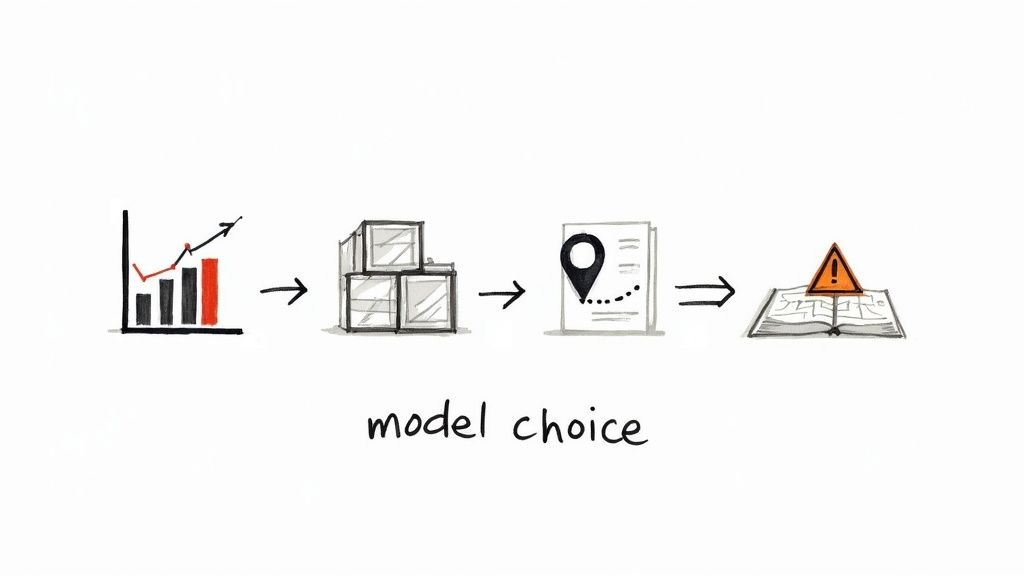

Choosing the Right AI Models for Your Needs

Alright, your data is clean and ready. Now comes the interesting part: picking the right tool for the job. It's a common mistake to think there’s a single, magical "AI model" that can fix every supply chain headache. That’s just not how it works.

In reality, different AI models are specialists. Each one is designed to tackle a specific operational challenge with a ton of precision. Success here isn’t about chasing the most complex algorithm; it’s about making a smart match between a model’s capability and your specific business need. This ensures you're putting AI's power exactly where it will make the biggest difference.

When we talk about AI for supply chain optimization, the real value shines through in four key areas: demand forecasting, inventory optimization, route planning, and anomaly detection. Each one needs a different kind of model and feeds on different data.

To make this clearer, here’s a quick breakdown of the most common models, what they do, and the kind of impact you can expect.

AI Model Selection for Supply Chain Tasks

| AI Model/Technique | Primary Use Case | Required Data Inputs | Expected Business Impact |

|---|---|---|---|

| Time-Series Models (e.g., ARIMA, Prophet) | Demand Forecasting | Historical sales data, seasonality, promotions, external factors (e.g., holidays, economic data). | 15-30% improvement in forecast accuracy, reduced stockouts and overstock. |

| Reinforcement Learning (RL) | Inventory Optimization | SKU-level sales data, lead times, storage costs, stockout costs, supplier reliability data. | Reduced carrying costs by 10-25%, improved service levels, optimized safety stock. |

| Route Optimization Algorithms (e.g., VRP Solvers) | Route Planning | Vehicle capacity, delivery addresses, time windows, driver schedules, real-time traffic, road closures. | 5-15% reduction in fuel costs and mileage, increased delivery capacity per vehicle. |

| Unsupervised Learning (e.g., Isolation Forest) | Anomaly Detection | IoT sensor data (temp, vibration), production line metrics, logistics tracking data, transaction logs. | Proactive issue resolution, reduced downtime, prevention of quality control failures. |

As you can see, the choice of model is directly tied to the problem you’re trying to solve. Let's dig into each of these areas a bit more.

Pinpointing Future Demand with Forecasting Models

Predictive demand forecasting is often the first, and most impactful, place to start. Traditional methods, like looking at last year's sales, are just too simple for today's market. They can’t possibly account for all the variables that shape what customers buy.

Machine learning models, on the other hand, are built to find patterns in the chaos. They can chew through dozens of inputs at once to generate forecasts that are worlds more accurate.

- Data Inputs: These models get smarter with more data. Think historical sales figures, seasonality, marketing promotions, competitor pricing, and even outside factors like economic news or the local weather.

- Business Impact: Better forecast accuracy directly cuts down on both stockouts (lost sales) and overstock (wasted capital). You capture more revenue and have less money tied up in inventory that isn’t moving.

Imagine a retailer gearing up for the holidays. Instead of just looking at last year, their AI model could analyze current social media trends and a competitor's ad schedule to predict demand for a hot new gadget with incredible confidence.

Achieving Perfect Balance with Inventory Optimization

While forecasting tells you what might sell, inventory optimization models tell you exactly how much to keep on hand and where to put it. These models are constantly performing a high-stakes balancing act between holding costs and the risk of a stockout.

They move way beyond simple reorder points. Instead, they calculate dynamic safety stock levels for every single SKU based on its unique demand patterns and supplier reliability. This is something that’s flat-out impossible to do well at scale with a spreadsheet.

These AI-driven systems aim for "just right" inventory levels—a state where you have precisely enough stock to meet demand without paying for warehouse space you don't need. It’s about surgical precision, not just educated guesses.

This intelligent approach pays off. Research shows that integrating AI can trim overall logistics costs by 5% to 20%, mostly by optimizing inventory and cutting waste. You can discover more insights about these supply chain trends to see the financial case laid out.

Navigating Logistics with Route Optimization

For any business that moves physical goods, route optimization is a goldmine of savings. AI algorithms can solve incredibly complex logistical puzzles, like the "Traveling Salesperson Problem," in real time. They figure out the absolute most efficient multi-stop routes for an entire fleet of vehicles.

Better yet, these models are dynamic. They can adjust routes on the fly as new information comes in.

- Real-Time Variables: They process live traffic data, weather alerts, road closures, and even last-minute changes to a customer’s delivery window.

- Key Outcomes: The results are immediate: lower fuel bills, less wear-and-tear on vehicles, shorter delivery times, and more deliveries per driver, per day.

This is the tech that allows a delivery service to instantly reroute a driver around a fender-bender, ensuring packages still get there on time and the customer stays happy.

Proactively Identifying Disruptions with Anomaly Detection

Finally, think of anomaly detection models as your supply chain's early warning system. These unsupervised learning models are trained to understand what "normal" looks like across your operations. They keep a constant watch on data streams from IoT sensors, production lines, and logistics systems.

The moment a data point strays from the norm—a sudden temperature spike in a refrigerated truck, an unusual delay at customs—the model flags it as a potential problem. This gives your team a chance to jump on the issue and fix it before it snowballs into a costly, chain-wide disruption.

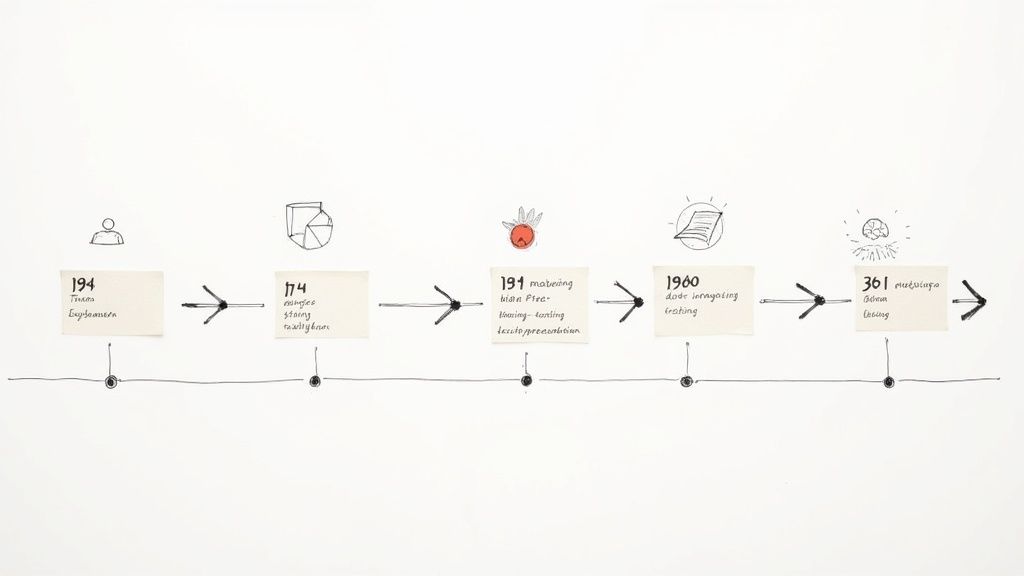

Executing a High-Impact AI Pilot Program

You’ve got a clear problem and a model that looks promising. Now it’s time to get out of the boardroom and into the real world. The single best way to do that is with a focused, high-impact pilot program. A well-run pilot is where you test your assumptions, prove the value of AI for supply chain optimization, and start building the momentum you'll need for a full-scale rollout.

This isn't about boiling the ocean. It’s about securing a quick, tangible win. We recommend a tight, 4-to-6-week timeline. That kind of pressure enforces discipline, keeps the team focused on what truly matters, and quickly shows if you’re on the right track. The goal here is to generate real results and build a killer business case without getting stuck in a multi-year project death march.

Think of the pilot as de-risking the entire initiative. It lets you learn fast, fail small, and iterate before you go asking for a major budget commitment.

Designing Your 4-to-6-Week Pilot Plan

A successful pilot needs a clear roadmap. This week-by-week structure keeps everyone aligned and makes sure you’re hitting the milestones that prove the model’s worth. Be agile, but stay organized.

Week 1: Assemble Your Team and Finalize Scope

Your first week is all about alignment. Kick things off by building a cross-functional "tiger team" with people who have skin in the game.

- Operations: The warehouse or logistics manager who lives and breathes the problem you’re solving.

- IT/Data Engineering: The person who actually knows where the data lives and how to wrestle it out of your systems.

- Data Science: The expert who’ll be building and fine-tuning the AI model.

- Business Leadership: A sponsor who can cut through red tape and champion the pilot to the C-suite.

Once the team is in place, lock down the scope. Revisit the KPIs you defined earlier and get hyper-specific about the dataset and operational slice you’ll target. If you’re piloting an inventory optimization model, maybe you scope it to a single product category in just one distribution center. Keep it small and manageable.

Weeks 2-3: Data Integration and Initial Model Training

This is where the technical work really starts. Your data engineering team will be building the pipelines to pull data from your ERP, WMS, and whatever other systems you’re using. That data then gets cleaned, formatted, and fed into the AI model for its first training runs.

This phase is a huge lift whether you're dealing with "brownfield" projects (integrating with clunky, legacy systems) or "greenfield" ones (building on modern infrastructure). With brownfield setups, expect to spend a lot of time creating workarounds for ancient APIs or manually cleaning messy data from outdated databases.

A classic mistake is underestimating the data integration effort. Be realistic. This phase almost always uncovers hidden data quality nightmares that you have to fix before the model can produce anything reliable.

By the end of this phase, you should have a baseline model spitting out its first set of predictions or recommendations.

Validating the Model and Building the Business Case

With an initial model up and running, the focus shifts from building to testing. This is where you prove, with hard numbers, that the AI approach is better than what you’re doing today.

Weeks 4-5: Testing and Validation Against Your Baseline

It's time to put the model through its paces. The best approach here is often a "shadow" test. Let your current processes run exactly as they are, but have the AI model run in parallel, making its own decisions.

For a demand forecasting pilot, you'd compare the model’s predictions for last week against your actual sales. For a route optimization pilot, you'd compare the AI’s suggested routes against the ones your drivers actually took, then calculate the difference in mileage, time, and fuel costs.

This side-by-side comparison against your baseline is everything. It gives you the cold, hard data needed to show a clear improvement, like a 20% reduction in forecast error or a 10% drop in miles driven.

Week 6: Analyzing Results and Presenting the Case

The final week is all about telling a compelling story with data. Consolidate your results and translate the pilot’s performance into a business case that executives can understand. Frame every outcome in terms of business value.

- Instead of: "The model's Mean Absolute Error was reduced."

- Say: "Our new forecasting model improved accuracy by 18%, which would have prevented $50,000 in stockouts last month alone."

Package these findings into a sharp, concise presentation for your stakeholders. Your goal is to get the green light for the next stage: a full-scale deployment. A successful pilot with a measurable ROI is the most powerful weapon you have for turning skeptics into champions and unlocking the budget for a company-wide initiative.

Scaling Your AI Solution and Proving ROI

A successful pilot is a huge win, but it’s really just the beginning. The true value of AI for supply chain optimization only shows up when your solution goes from a promising experiment to an essential part of your daily operations. This is the scaling phase—and it’s just as much about people and process as it is about technology.

Moving from a controlled pilot to a full-scale deployment isn’t as simple as flipping a switch. You’re fundamentally changing how your teams make critical decisions about inventory, logistics, and forecasting. Getting this right is how you turn a pilot’s initial success into sustained, long-term business impact.

Choosing Your Deployment Pattern

How you weave the AI into your existing workflows is a make-or-break decision. There’s no single right answer here; the best approach depends on your technical maturity, the problem's complexity, and frankly, how much automation your team is ready to handle.

Here are the most common deployment models we see in the field:

- API-Based Integration: The AI model operates as a standalone service, talking to your current systems (like an ERP or WMS) through an Application Programming Interface (API). This gives you incredible flexibility. It’s perfect for feeding AI-generated demand forecasts directly into your inventory software without having to rip everything out and start over.

- Human-in-the-Loop System: In this setup, the AI acts more like a co-pilot. It suggests an optimized delivery route or a recommended purchase order, but a human operator has the final say. This is a fantastic way to build trust and ease teams into new processes, especially when the stakes are high.

- Fully Automated Decision System: This is the most advanced pattern, where the AI is trusted to make and execute certain decisions on its own, within carefully defined guardrails. For instance, an AI could automatically reorder low-priority items once they hit a dynamically calculated threshold, freeing up your team to handle more strategic work.

Start with a less disruptive pattern, like a human-in-the-loop system, to build confidence. As your team sees the AI's reliability firsthand, you can gradually dial up the level of automation.

Mastering Change Management and Building Trust

Let's be honest: the technology is often the easy part. The people are the hard part. Your team, from planners to warehouse staff, might be skeptical or even resistant to AI-driven recommendations. If they don't trust the tool, they won’t use it, and your investment goes down the drain. This makes proactive change management non-negotiable.

Your focus should be on building trust through transparency and training. Your team needs to understand why the AI is suggesting something, not just what the suggestion is. This is where "explainable AI" (XAI) is so critical. Instead of a black box, a good system will show its work, highlighting the key factors—like a sudden spike in social media mentions or a competitor's promotion—that influenced its forecast.

A solid change management plan always includes:

- Targeted Training Sessions: Go beyond just showing them how to click buttons. Explain the "why" behind the new workflow and how it makes their job easier and more strategic.

- Creating AI Champions: Find the early adopters on your teams who are genuinely excited about the technology. Give them the support to become internal advocates and peer trainers.

- Establishing Feedback Loops: Create a simple, clear channel for users to report issues, ask questions, and suggest improvements. Acting on their feedback shows the team they're part of the solution's evolution, not just subject to it.

A Framework for Measuring True ROI

To get the green light for scaling your AI solution, you need to prove its financial impact with cold, hard numbers. The KPIs from your pilot are a great start, but to build a bulletproof business case, you have to connect those operational wins directly to the bottom line.

The 2025 Stanford AI Index backs this up, highlighting that investments in AI for supply chain optimization deliver some of the highest returns across all business functions. With 78% of organizations now using AI in some form, its application in supply chain and inventory management consistently shows a superior financial impact. You can learn more about these AI investment findings.

Here’s a look at the kind of metrics you should be tracking before and after your AI implementation to make your case.

Key Metrics for Measuring AI ROI in Supply Chain

| Metric Category | Specific KPI | Before AI (Baseline) | After AI (Target) |

|---|---|---|---|

| Inventory Management | Inventory Carrying Costs | $2.5M / year | <$2.0M / year |

| Stockout Rate (Top SKUs) | 12% | <4% | |

| Logistics & Fulfillment | Cost Per Delivery | $18.50 | $16.00 |

| On-Time, In-Full (OTIF) Rate | 89% | >96% | |

| Forecasting & Planning | Forecast Accuracy (MAPE) | 25% | <15% |

| Planner Intervention Rate | 30% of forecasts | <10% of forecasts |

By tracking these metrics diligently, you build a powerful story. You can walk into any boardroom and state with confidence: "Our AI initiative cut carrying costs by $500,000, improved our delivery performance, and freed up our planners to focus on strategic growth."

To see how these principles are applied in the real world, check out this case study on the Supply Chain Sense project, which breaks down a practical application of AI for operational intelligence.

Common Questions About AI in Supply Chain

Even with a solid plan, you're going to have questions. That's a given with any major tech initiative. When it comes to AI for supply chain optimization, we see the same concerns pop up over and over again. Let's tackle them head-on to clear up the confusion and give you the confidence to move forward.

Here are the direct, practical answers to the questions we hear most from operations leaders.

What's the Biggest Challenge of AI Implementation?

Surprisingly, it’s almost never the AI technology itself. The real hurdles are data quality and organizational change management. It’s a classic two-headed problem. Most companies are sitting on a goldmine of data, but it’s often scattered across different systems, incomplete, or just plain inconsistent.

AI models live and breathe data. If you feed them garbage, you'll get garbage out—no matter how sophisticated the algorithm is. Getting your data house in order isn't just a recommendation; it's a non-negotiable prerequisite.

Then there's the human element, which is just as critical. Your team might be skeptical of AI-driven recommendations, fearing their jobs are at risk or simply not trusting a "black box." A successful project needs a dual focus: invest in a rock-solid data foundation while building a serious plan to train, support, and empower your people to work with the new tools, not against them.

The real win isn’t just plugging in a smart algorithm. It’s building a culture where data-driven insights are trusted and acted upon. That takes just as much focus on people as it does on platforms.

Should We Build or Buy an AI Solution?

The "build vs. buy" debate is a classic for a reason. There’s no single right answer—it all comes down to your company's resources, in-house expertise, and what you're trying to achieve long-term.

Here’s how the paths usually break down:

- Building In-House: This route gives you ultimate control and a perfectly customized solution. It’s a good fit for massive enterprises with truly unique, thorny problems and the deep pockets needed to hire and keep a dedicated team of data scientists and engineers. Just be ready for a hefty upfront investment and continuous maintenance costs.

- Buying a Third-Party Platform: Going with an off-the-shelf SaaS solution is almost always faster and more cost-effective to get started. You get the benefit of the vendor's deep expertise and constant updates without having to manage the tech stack yourself. This is an excellent path for solving common problems like demand forecasting or route planning.

There's also a popular hybrid approach. You buy a core platform to handle 80% of the work, then use your internal team to build smaller, custom models that plug into it via APIs. This can give you a great balance of speed and tailored functionality, letting you focus your best people on the problems that are unique to your business.

How Do We Ensure Security and Compliance?

Security and compliance can't be an afterthought—they have to be baked into your AI strategy from the very beginning. When AI models are influencing major operational and financial decisions, you absolutely have to protect the data and the integrity of the system.

First, conduct a thorough risk assessment of the data you'll be using, especially any sensitive customer or supplier information. From there, you need to establish clear data governance policies that spell out who can access what, how it can be used, and where it's stored.

When you're looking at third-party vendors, do your homework. Dig into their security credentials, like ISO 27001 or SOC 2 certifications, and read their data privacy policies carefully. Make sure they comply with regulations like GDPR or CCPA that apply to your business.

If you're building models in-house, your development process must include dedicated security checks and ethical AI reviews. These steps are crucial for preventing data leaks, rooting out algorithmic bias, and making sure the model behaves predictably. And it doesn't stop at launch—regular audits and ongoing monitoring are essential to stay compliant and defend your newly intelligent supply chain from threats.

At Red Brick Labs, we specialize in designing and building custom AI automation that integrates seamlessly into your existing workflows. We handle the technical complexity so you can focus on the results—like cutting operational costs and boosting efficiency. Discover how we can architect an intelligent automation solution for your supply chain.