Improving your supply chain is a puzzle with four crucial pieces: diagnosing where you are now, smartly applying technology like AI, running focused pilot programs to prove what works, and then scaling up your wins. When you get this right, your supply chain stops being a cost center and becomes a genuine competitive edge. It’s all about getting ahead of problems instead of constantly reacting to them.

Why Supply Chain Efficiency Is No Longer Optional

The days of treating supply chain management as a quiet, back-office function are long gone. In today's volatile market, efficiency is the engine that drives both profitability and resilience. Even a seemingly small delay, one mismanaged shipment, or a bit of excess inventory can send ripples straight to your bottom line.

Rising operational costs, customers who expect next-day delivery, and unpredictable global events have turned optimization from a "nice-to-have" into a core business imperative. Companies that don't adapt aren't just losing money—they're putting their entire market position at risk.

The Real Cost of Inefficiency

The financial toll of a clunky supply chain is staggering. Recent disruptions have forced companies to swallow financial losses averaging around 8% of their annual revenues. This pressure has, understandably, pushed investment in automation and visibility tools to the top of the priority list.

In fact, 82% of supply chain organizations have boosted their IT spending to get these critical technologies in place. It's a move that's both defensive and a clear play for a competitive advantage.

An inefficient supply chain doesn't just cost money—it erodes customer trust, burns out employees with manual work, and makes it impossible to scale effectively. It's a silent tax on every single part of your business.

This guide is your roadmap to move beyond constantly fighting fires. We'll walk you through how to systematically diagnose your current processes, pinpoint the high-impact opportunities for improvement, and implement changes that deliver real, measurable results.

Moving from Reactive to Proactive

A truly efficient supply chain sees problems coming before they hit. It's about building a system that is both lean and agile—one that can handle disruptions without grinding to a halt. To get a deeper sense of why this is so critical right now, check out this ultimate guide to supply chain evolution. This requires a fundamental shift in mindset, backed by the right data and technology.

This transformation is built on a few core strategic areas. We've outlined them below to give you a quick reference for the journey ahead.

Key Pillars for Improving Supply Chain Efficiency

| Pillar | Objective | Key Actions |

|---|---|---|

| Visibility | Gain a real-time, end-to-end view of your entire operation. | Implement tracking technologies, centralize data, and establish a single source of truth. |

| Automation | Eliminate manual, repetitive tasks that cause errors and delays. | Identify high-ROI automation targets like order processing, inventory updates, and invoicing. |

| Data-Driven Decisions | Use analytics to forecast demand and optimize inventory. | Leverage historical data and predictive analytics to spot trends and identify bottlenecks. |

| Collaboration | Strengthen relationships with suppliers and partners. | Create shared data platforms and transparent communication channels for a more responsive network. |

By focusing on these pillars and following the steps in this guide, you can start building a supply chain that doesn't just save money but actively fuels business growth and keeps your customers happy.

Get Your Hands Dirty with a Practical Supply Chain Health Audit

Before you can even think about improving your supply chain, you need a brutally honest look at how it's running right now. You can't fix what you can't see. A proper health audit is like flipping on the lights in a messy garage—it shows you all the hidden bottlenecks, wasteful steps, and data black holes that are quietly costing you money.

The goal here isn't just to gather a bunch of data. It's about building an airtight case for change. This means mapping your entire operational flow, from the moment an order is placed to the second it lands on the customer's doorstep. Only then can you find exactly where time and money are slipping through the cracks.

Map Your End-to-End Processes

Your first job is to trace every single touchpoint. Forget high-level flowcharts; this needs to be a granular, step-by-step map of what actually happens, not what's supposed to happen. Follow an order through its entire lifecycle and ask the tough questions at each stage. Who touches it? What software is involved? How long does each step really take?

We saw a mid-sized electronics distributor do this recently. They always assumed their procurement approval was fast, but the mapping exercise revealed it added three whole days to their lead times because of manual handoffs between departments. This one bottleneck was chronically delaying restocks of their most popular items, directly leading to lost sales.

That's the kind of insight you'll never find without a detailed map. As part of this, you should also be looking for quick wins. For example, assessing your shipping patterns might reveal opportunities for effective freight consolidation strategies, which can seriously cut down costs on smaller, frequent orders.

Focus on KPIs That Actually Matter

You're probably drowning in data, but most of it is just noise. A good audit cuts through the static and zooms in on the handful of Key Performance Indicators (KPIs) that truly signal efficiency. Ditch the vanity metrics and concentrate on the numbers that hit your operations and your bottom line.

Here are the big ones to watch:

- Order Cycle Time: The total clock time from a customer's click to the package arriving. If this number is high, you've got friction somewhere in your order processing, picking, or shipping.

- Inventory Turnover: This tells you how quickly you're selling through your entire stock. A slow turnover is a huge red flag—it often means you have capital tied up in overstocked, obsolete, or slow-moving products.

- On-Time-In-Full (OTIF): What percentage of your orders arrive perfectly? That means the right stuff, in the right quantity, at the right place, at the promised time. A low OTIF score is a direct hit to customer satisfaction and points to deep problems in your fulfillment process.

Tracking these KPIs gives you a hard, quantitative baseline. It turns vague feelings like "we think we're a bit slow" into concrete facts like, "our average order cycle time is 72 hours, which is 48 hours longer than our main competitor."

A proper audit isn't about assigning blame. It's about creating a single source of truth that everyone can agree on. The data you uncover becomes the bedrock for every decision you make next, giving you the proof you need to justify investing in new tools and process changes.

Uncover Hidden Warehouse Inefficiencies

The warehouse is often a goldmine for easy improvements. A consumer packaged goods company we know noticed their pick-and-pack times had nearly doubled over six months. By simply walking the floor and observing, they found the culprit: a terribly organized layout. Their fastest-moving items were stored in the back of the warehouse, forcing pickers to trek unnecessary distances for almost every single order.

This is a classic problem that’s incredibly easy to fix once you spot it. Smart warehouse organization is foundational to an efficient operation. If you want to dig deeper here, our guide on inventory management best practices is packed with practical strategies for optimizing how you store and retrieve your products.

By combining detailed process mapping, sharp KPI analysis, and some old-fashioned, on-the-ground observation, your health audit will give you a clear, data-driven diagnosis of your supply chain’s weak spots. This is the essential first step to making targeted improvements that deliver real impact.

Finding High-Impact AI and Automation Opportunities

You’ve done the hard work of diagnosing your supply chain’s health. Now it’s time to connect those findings to real-world action. This is where we shift from identifying problems to strategically solving them with the right technology.

The goal isn't to chase every shiny new tool. It's about pinpointing the practical AI and automation opportunities that will give you the highest—and fastest—return on your investment.

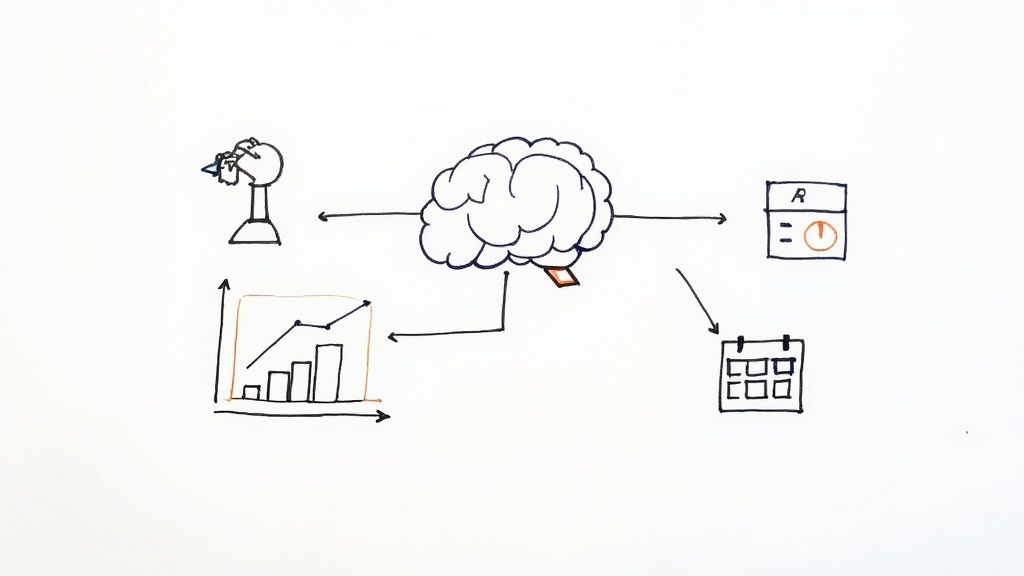

These technologies are so effective because they directly attack the two biggest enemies of an efficient supply chain: uncertainty and repetitive manual work. AI is brilliant at spotting patterns in messy data to reduce uncertainty, while automation is built to handle the tedious, rule-based tasks that bog your team down.

Where AI Delivers the Biggest Wins

Forget the buzzwords. At its core, AI is a powerful tool for making smarter predictions. By churning through historical sales data, market trends, and even outside factors like weather patterns, AI models can dramatically improve your ability to see what’s coming.

This is especially game-changing in a couple of key areas:

-

Smarter Demand Forecasting: Traditional forecasting methods often miss the subtle signals that lead to stockouts or expensive overstock. AI models, on the other hand, can anticipate seasonal demand surges with incredible accuracy. I saw a CPG company use an AI model to predict a spike in demand for outdoor products, letting them adjust inventory and cut stockouts by 40% during their peak season.

-

Predictive Maintenance: In manufacturing and logistics, an unexpected equipment failure can grind everything to a halt. AI-powered sensors can monitor machinery health in real time, predicting when a part is about to fail before it actually breaks. This moves you from reactive, costly emergency repairs to planned, proactive maintenance that minimizes downtime.

Early adopters are already seeing massive gains. Recent industry data shows that companies using AI in their supply chain management have cut logistics costs by 15%, slashed inventory levels by 35%, and boosted service efficiency by a staggering 65%.

Unlocking Value with Practical Automation

While AI tackles complex predictions, automation is your go-to for streamlining the high-volume, repetitive tasks that drain your team's time and invite human error. Think of it as building a digital workforce to handle the grunt work, freeing up your people for more strategic thinking.

The best automation targets are tasks that are highly repetitive, rule-based, and involve moving data between different systems. These are your "quick wins" that deliver immediate value and build momentum for larger projects.

Here’s where to start looking for those high-impact opportunities:

-

Warehouse Operations: Automating picking and packing with robotics or even simple guided systems can drastically increase throughput and accuracy. Even a basic software automation can optimize picking routes to cut down on wasted travel time in the warehouse.

-

Administrative Workflows: Mundane jobs like processing invoices, generating shipping labels, and updating inventory records are perfect candidates for Robotic Process Automation (RPA). We worked with a 3PL provider that implemented RPA for its invoicing process. The result? They freed up 20 hours of manual work every single week and completely eliminated data entry errors.

The clues for where to start are right in your audit. Where did you find the most manual handoffs? Where do errors pop up most frequently? Those are your starting points. Our guide on automation in procurement dives deeper into how you can apply these same ideas to your purchasing processes.

By zeroing in on these high-impact areas first, you'll build a solid foundation for a smarter, more efficient supply chain, proving the value of technology one targeted improvement at a time.

Designing and Running an Effective Pilot Program

Jumping headfirst into a massive technology rollout is a classic, and often costly, mistake. A much smarter play is to test the waters with a focused, low-risk pilot program.

Jumping headfirst into a massive technology rollout is a classic, and often costly, mistake. A much smarter play is to test the waters with a focused, low-risk pilot program.

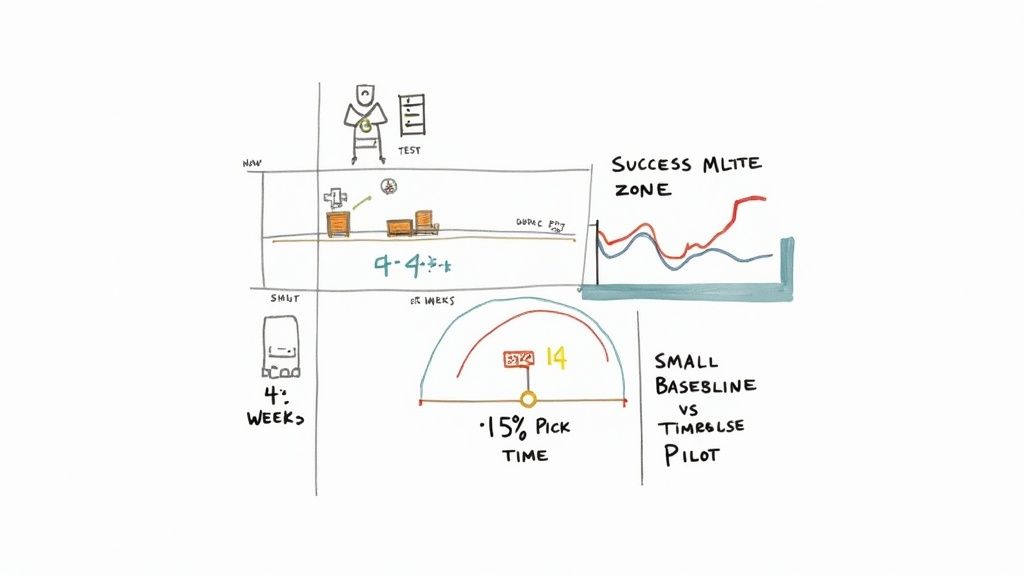

Think of it as a small-scale laboratory for your supply chain. This approach lets you prove the value of a new process or tool in a controlled environment, gather hard data, and iron out the kinks before you commit to a major investment. It’s not about boiling the ocean; it’s about isolating one specific problem and testing one potential solution without disrupting your entire operation.

Define a Narrow and Measurable Scope

The secret to a successful pilot? A laser-focused scope. Instead of trying to automate your entire warehouse, pick one high-friction area and go deep. This keeps the project manageable and gives you a clean, apples-to-apples comparison against your baseline performance.

Your scope should be tight enough to be completed within a 4–6 week sprint. This creates a healthy sense of urgency and ensures you get actionable results fast.

Here are a few examples of a well-defined pilot scope:

- Warehouse Automation: Forget the whole facility. Implement an automated picking system in one zone—specifically, the one responsible for your top 20 fastest-moving SKUs.

- Forecasting AI: Don’t overhaul your entire demand planning process. Apply a new AI forecasting model to a single, notoriously unpredictable product category, like seasonal apparel or promotional items.

- Supplier Collaboration: Instead of a mass onboarding, bring just three of your most critical suppliers onto a new real-time communication platform to track raw material shipments.

For each of these, the "before" and "after" is crystal clear. You can track performance against your existing KPIs and see the real-world impact of your targeted change.

Set Crystal-Clear Success Metrics

Before you kick things off, you have to define what a “win” looks like in cold, hard numbers. Vague goals like “improve efficiency” are useless here. You need concrete, measurable targets that leave zero room for interpretation.

Your success metrics should be directly tied to the pain points you uncovered in your initial audit.

Your pilot isn’t just a test of the technology—it’s a test of your hypothesis. Your hypothesis might be, "By automating picking in Zone A, we can reduce average pick time by 15%." The pilot is designed to prove or disprove this with data.

Here’s how you can structure your success metrics:

| Pilot Focus | Primary KPI | Success Target |

|---|---|---|

| Automated Picking | Pick-to-Ship Cycle Time | Reduce by 15% |

| AI Forecasting | Stockout Rate | Decrease by 25% |

| Order Processing RPA | Cost Per Order | Lower by $0.50 |

| Invoicing Automation | Manual Processing Time | Cut by 80% |

This level of clarity is non-negotiable. It’s what allows you to objectively evaluate the pilot and build an undeniable business case for a wider rollout.

Track Performance and Measure the True Impact

Once your pilot is live, meticulous tracking is everything. You need to collect data on your chosen KPIs daily. This isn't just about the final report; it's about seeing the day-to-day fluctuations and spotting unexpected challenges as they pop up.

For example, your picking zone automation might be hitting its time-reduction goals, but you notice it's creating a new bottleneck at the packing station. That’s an invaluable insight you would’ve completely missed without close monitoring. For a closer look at how focused data analysis can drive these kinds of operational gains, this case study on Supply Chain Sense shows the power of connecting the right data points to solve specific problems.

By the end of your 4–6 week sprint, you won't have an opinion—you'll have proof. You’ll have a data-backed story that shows what works, what doesn't, and what the real ROI is. And that’s exactly what you need to get the buy-in for what comes next.

Building the Business Case for a Full Rollout

A successful pilot doesn't just improve a process—it gives you a story, backed by undeniable proof. Now it’s time to turn those hard-won results into a compelling business case that gets the C-suite on board. This isn't about dumping a spreadsheet on their desk. It's about crafting a clear narrative that connects your pilot’s success directly to the company's bottom line.

You’ve done the hard work and generated the data. The next step is to present that data through a financial lens. Leadership needs to see more than just a process getting faster; they need to understand how that speed translates into dollars saved or revenue gained.

Quantifying the Success of Your Pilot

To build a powerful case, you have to anchor your report in tangible financial outcomes. Vague statements won't secure a budget, but concrete numbers will. Frame your results around the metrics that actually matter to senior leadership. It's time to move beyond operational jargon and speak their language: cost, revenue, and risk.

Your analysis should spotlight a few key areas of financial impact:

- Reduced Labor Costs: Calculate the exact number of manual hours the new process eliminated. For instance, if your pilot automated invoicing for one product line and saved 15 hours per week, you can easily extrapolate that to show a potential $30,000 annual saving when scaled across all lines.

- Faster Fulfillment Cycles: Connect shorter cycle times to better cash flow. Shaving even 24 hours off your order-to-cash cycle means the company gets paid faster. That’s a huge win for the finance department and an easy concept for anyone to grasp.

- Lower Inventory Carrying Costs: Show how better forecasting or streamlined logistics from your pilot reduced the capital tied up in excess stock. Even a modest 5% reduction in safety stock can translate into substantial savings that catch an executive's eye.

- Improved Customer Satisfaction: Draw a direct line from higher On-Time-In-Full (OTIF) rates to customer retention. An increase in your OTIF score from 85% to 98% in the pilot group means fewer costly re-shipments and happier, more loyal customers.

This approach transforms your pilot from a simple operational test into a proven strategy for improving the company's financial health.

A strong business case doesn't just show what you achieved in the pilot. It projects those wins across the entire organization to paint a clear picture of the full-scale opportunity.

Creating a Clear ROI Calculation

To make the investment decision as easy as possible, present a straightforward Return on Investment (ROI) calculation. Sometimes, the most effective tool is a simple table that lays out the value proposition at a glance. It's an honest comparison of your costs versus the tangible financial benefits your pilot delivered.

Here’s a simple framework to show how you can calculate the ROI from a pilot program.

Pilot Program ROI Calculation Framework

This table breaks down the financial impact by comparing key metrics before and after the pilot, then annualizing the savings to show the bigger picture.

| Metric | Baseline (Pre-Pilot) | Result (Post-Pilot) | Financial Impact ($) |

|---|---|---|---|

| Labor Cost Per Order | $4.50 | $2.75 | $17,500 (Annualized) |

| Inventory Carrying Cost | $120,000 (Annual) | $105,000 (Projected) | $15,000 (Annualized) |

| Expedited Freight Costs | $8,000 (Monthly) | $3,500 (Monthly) | $54,000 (Annualized) |

| Total Annualized Savings | $86,500 |

A clean, simple framework like this instantly shows the direct financial gains and provides a rock-solid foundation for justifying the resources needed for a full rollout.

Analyzing and Presenting Lessons Learned

Finally, a credible business case is always a transparent one. Don't be afraid to be candid about what worked, what didn’t, and what needs a little tweaking. Did the software integration take longer than you planned? Did employees need more training than you first anticipated?

Addressing these challenges head-on shows foresight and builds trust. It proves you’re not just celebrating a win but that you have a realistic, battle-tested plan for a smooth and successful organization-wide implementation. This kind of honesty is what gives you the undeniable proof needed to secure the resources and scale your initiative.

Scaling Your Success and Managing Organizational Change

You’ve run a successful pilot. The numbers look great, the tech works, and you’ve proven the concept. Congratulations. Now comes the hard part.

Scaling a pilot program is less about the technology and more about the people. The real challenge isn’t just rolling out new software; it’s embedding a new way of working across the entire organization. This is where most initiatives either succeed spectacularly or quietly fizzle out.

Simply handing teams new tools and expecting them to adapt is a recipe for failure. You need a deliberate strategy to get everyone on board, handle the inevitable friction of new workflows, and ensure the data fueling your shiny new systems is clean and reliable.

Communicating the Why and Training for the How

The first rule of managing change is to over-communicate. Your teams don’t just need to know what is changing; they need to understand why it matters to them personally. Frame the rollout around the direct benefits to their daily work—less tedious data entry, fewer mistakes to chase down, and more time for tasks that actually require their brainpower.

For instance, when introducing an automated invoicing system, don't just talk about corporate cost savings. Emphasize that it will eliminate 10-15 hours of manual data entry per week for the finance team, freeing them up for strategic analysis. This reframes the change from a top-down mandate to a shared improvement.

Once the "why" is clear, you need a robust plan for the "how."

- Tailor the Training: Warehouse staff need hands-on practice with new scanners, not a lecture on forecasting algorithms. Planners need a deep dive into the new dashboard's nuances. One-size-fits-all training doesn’t work.

- Anoint "Super Users": In every department, you'll find a few people who just get it faster than others. Identify these enthusiastic team members, give them extra training, and empower them as internal champions. They provide invaluable peer-to-peer support and build momentum from the ground up.

- Offer Ongoing Support: A single training session is never enough. You need to establish clear, accessible channels for help, whether it's a dedicated helpdesk, weekly Q&A sessions, or an internal library of quick video tutorials.

Managing organizational change is all about building trust. When your people see you've invested time and resources into making their transition smooth and supported, they're far more likely to embrace the new way of working.

Getting Serious About Data Governance

As you scale automation and AI, the quality of your data shifts from being important to being non-negotiable. These intelligent systems are powerful, but they’re only as smart as the information you feed them. The old adage, "garbage in, garbage out," has never been more true.

This is where data governance comes in. It's not the most glamorous topic, but it’s the bedrock of any successful digital transformation. Think of it as the framework of rules, processes, and responsibilities that keeps your data consistent, trustworthy, and secure.

Your new automation engine is a high-performance race car. Data governance is the pit crew ensuring it’s always filled with the highest-quality fuel. A solid plan will clearly define:

- Data Ownership: Who is ultimately responsible for the accuracy of customer addresses? Who maintains product SKU information? Assigning clear ownership is the first step.

- Data Standards: What are the uniform formats for entering data across all systems? Simple things like standardizing date formats or state abbreviations prevent countless errors down the line.

- Access Controls: Who has permission to view, create, or modify different types of data? This is critical for both security and data integrity.

By pairing a human-first approach to change management with a disciplined strategy for data governance, you create an environment where your supply chain improvements can actually take root and grow. This dual focus ensures your solution doesn't just work on launch day but continues to deliver value for years to come.

Common Questions and How to Sidestep Project Killers

When we talk to leaders about overhauling their supply chain, the same questions always come up. People are excited about the potential but rightly cautious about the execution. Here are a few of the most common ones we hear, along with some hard-won advice.

"What's the single best first step we can take?"

Everyone wants to jump straight to the sexy new AI tool, but the only right answer is a thorough, honest audit of your current processes. You simply cannot improve what you don't measure.

Establishing clear baseline KPIs is the non-negotiable starting point. Without it, you're just guessing.

"How long until we actually see a return on this?"

This is a two-part answer. A well-scoped pilot program, focused on a specific high-pain, high-ROI area, can show positive results in as little as 4–6 weeks. Getting that quick win is crucial for building momentum and getting skeptics on board.

However, realizing true, enterprise-level ROI is a longer journey. Depending on the complexity of the rollout and how deeply integrated the changes are, most companies begin to see significant, widespread financial benefits within 12–18 months.

What Are the Biggest Project Risks?

Understanding what can go wrong is just as important as having a great plan. Over the years, we've seen three pitfalls that consistently derail these kinds of initiatives.

-

Garbage In, Garbage Out. This old saying is truer than ever with AI. Poor data quality will undermine even the most advanced tools. Inaccurate, inconsistent, or incomplete data is a recipe for failure. The fix? Establish strong data governance rules before you even think about implementation.

-

Your Team Fights It. If your people on the ground see new technology as a threat rather than a tool to make their jobs easier, they will resist it. Sometimes actively, sometimes passively. Both are deadly to a project. Proactive communication, clear "what's-in-it-for-me" messaging, and hands-on training are non-negotiable.

-

The "Solution" Doesn't Fit the Problem. It’s easy to get wowed by a slick sales demo. But choosing a tool that doesn't fit your specific, real-world workflow is a fantastically expensive mistake. Always, always start with a focused pilot to validate a solution's fit for your unique operational needs before you sign a massive contract.

Ready to move beyond pilots and build scalable AI workflows that deliver measurable ROI? Red Brick Labs designs and implements custom automation that eliminates manual work and optimizes your operations. Start your process discovery with us today.