In today's competitive landscape, incremental gains are no longer enough. The standard playbooks for efficiency have hit a wall, delivering marginal improvements at best. The key to unlocking a significant reduction in operational costs, often between 30-60%, isn't just working harder; it's working smarter through structured, data-driven improvement cycles. True transformation requires moving beyond abstract theories and into practical application.

This guide provides a tactical blueprint, showcasing detailed, real-world continuous improvement process examples from leading organizations. We will dissect the exact methodologies and AI-powered tools they used to overhaul core business functions, including recruiting, document processing, and supply chain management. The goal is to give you a replicable framework for diagnosing your own operational bottlenecks and implementing intelligent automation effectively.

You will learn not just what these companies did, but precisely how they executed their strategies. Each example breaks down the process from initial discovery and pilot testing to full-scale deployment, highlighting the measurable gains in speed, accuracy, and cost-efficiency achieved along the way. Consider this your roadmap for turning repetitive, error-prone tasks into a sustainable strategic advantage. For those looking to explore more advanced methodologies, you can visit Parakeet AI's blog for continuous improvement insights for deeper analysis and emerging trends.

Get ready to explore concrete case studies that illustrate the power of combining proven frameworks like Lean Six Sigma and Kaizen with modern tools like process mining and RPA, providing actionable insights you can apply immediately.

1. Lean Six Sigma

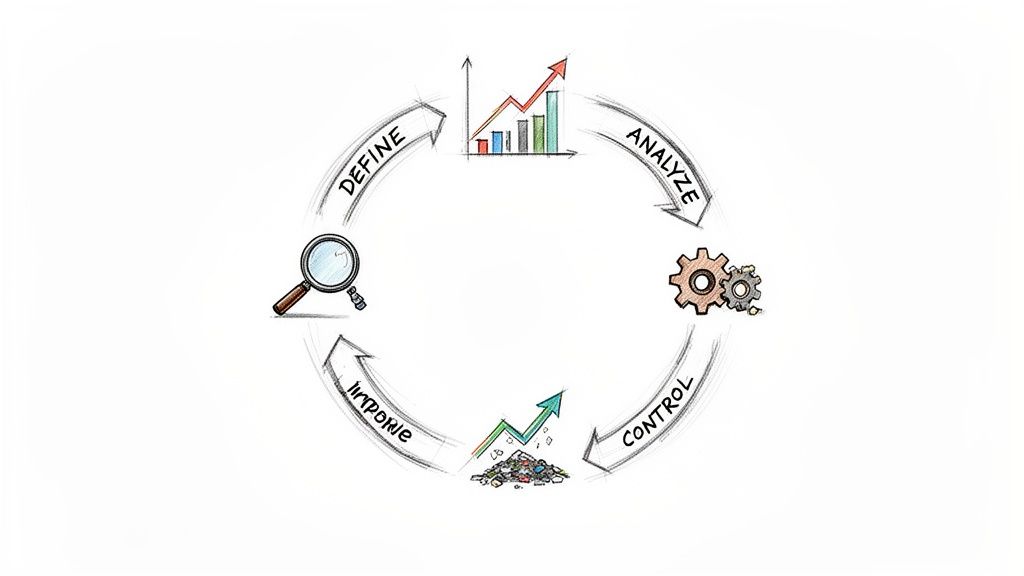

Lean Six Sigma is a powerhouse methodology that merges the waste-elimination focus of Lean with the defect-reduction power of Six Sigma. It provides a structured, data-driven framework called DMAIC (Define, Measure, Analyze, Improve, Control) to systematically root out inefficiency and variation in any business process. This approach is foundational for any organization serious about operational excellence, making it a prime example of a continuous improvement process.

For teams exploring AI and automation, Lean Six Sigma provides the analytical rigor needed to justify investments. It forces you to baseline current performance, quantify the precise cost of inefficiencies (in time, money, or errors), and later, validate the ROI of new technology with hard data.

How Lean Six Sigma Drives Improvement

The strength of Lean Six Sigma lies in its systematic DMAIC cycle. This five-phase approach prevents teams from jumping to solutions before fully understanding the problem. It ensures changes are based on evidence, not assumptions, leading to more sustainable and impactful improvements.

- Define: Clearly articulate the business problem, goals, and scope.

- Measure: Collect baseline data to quantify the current process performance.

- Analyze: Use statistical analysis to identify the root cause(s) of defects and variation.

- Improve: Develop, test, and implement solutions to address the root cause(s).

- Control: Establish monitoring systems to sustain the gains and prevent the process from regressing.

Actionable Takeaways for Implementation

To apply Lean Six Sigma effectively, especially as a precursor to automation, focus on a targeted approach.

Strategic Insight: Use the DMAIC framework not just to improve a process, but to build the business case for automation. The 'Measure' and 'Analyze' phases produce the exact data you need to calculate potential ROI and secure stakeholder buy-in for technology investments.

- Start with High-Impact Processes: Target high-volume, repetitive workflows where small variations have a significant financial or customer impact. Think invoice processing, customer onboarding, or inventory management.

- Document the "As-Is" State: Before designing an AI-powered solution, use value stream mapping (a Lean tool) to meticulously document the current process. This uncovers hidden bottlenecks and waste that technology can directly address.

- Instrument Before You Improve: Partner with a firm like Red Brick Labs to establish clear baseline metrics before starting an automation pilot. This ensures you can accurately measure the "before and after" impact on cost, speed, and accuracy.

- Train Cross-Functional Champions: Empower teams from different departments to understand and apply basic Lean Six Sigma principles. This fosters a culture where everyone is equipped to identify improvement opportunities and sustain the gains long-term.

2. Kaizen (Continuous Improvement Culture)

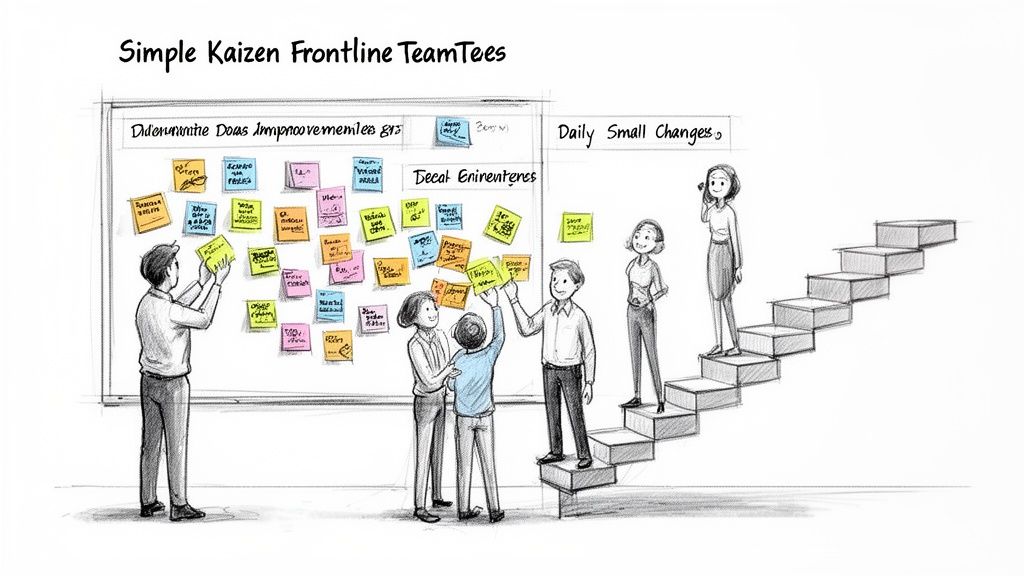

Kaizen is a Japanese philosophy that translates to "change for the better," focusing on continuous, incremental improvements driven by every employee. Unlike top-down overhauls, Kaizen fosters a culture where frontline teams are empowered to identify and solve daily inefficiencies. This grassroots approach makes it one of the most sustainable continuous improvement process examples, building a foundation of operational awareness that is essential for long-term success.

For organizations looking to leverage automation, a Kaizen culture is invaluable. It trains employees to constantly scan for friction, waste, and repetitive tasks, creating a pipeline of well-defined opportunities for AI-powered solutions. Instead of forcing technology onto processes, the demand for automation emerges organically from the teams who know the work best.

How Kaizen Drives Improvement

Kaizen's power comes from its emphasis on small, frequent changes rather than large, disruptive projects. By making improvement a daily habit, it compounds gains over time and embeds a proactive mindset across the organization. This is often facilitated through simple but effective practices that encourage participation from everyone.

- Gemba Walks: Managers go to the "real place" where work happens to observe processes firsthand and engage with frontline staff.

- Suggestion Systems: Formal channels are created for employees to submit improvement ideas, with clear feedback and reward mechanisms.

- Daily Huddles: Short, standing meetings where teams discuss daily goals, identify immediate roadblocks, and flag small opportunities for improvement.

- PDCA Cycle (Plan-Do-Check-Act): A simple, iterative four-step method for testing and implementing changes in a controlled way.

Actionable Takeaways for Implementation

To build a Kaizen culture that fuels your automation strategy, focus on empowering teams and creating feedback loops that surface high-value opportunities.

Strategic Insight: A mature Kaizen culture transforms your workforce into a distributed process discovery engine. Instead of relying solely on analysts, your frontline teams become the primary source for identifying high-ROI automation candidates, ensuring solutions address real-world pain points.

- Launch an "Automation Idea" Challenge: Create a simple system (like a shared document or Slack channel) where any employee can submit a repetitive task they believe could be automated. This builds a backlog of vetted use cases.

- Empower with "No-Code" Tools: Provide teams with user-friendly automation platforms. This allows them to build simple bots for their own tasks, fostering a sense of ownership and demystifying AI technology.

- Incorporate Kaizen into Post-Deployment: After an AI solution goes live, use Kaizen principles to gather feedback. Host regular check-ins with users to identify small ways to refine the bot’s logic, improve its accuracy, or expand its capabilities.

- Recognize and Reward Process Pioneers: Publicly celebrate employees and teams who identify significant improvement opportunities or successfully implement small-scale automations. This reinforces the value of a continuous improvement mindset.

3. Business Process Management (BPM) with RPA Integration

Business Process Management (BPM) is a systematic discipline that involves modeling, analyzing, measuring, improving, and optimizing business processes. It provides the architectural blueprint for how work gets done. When combined with Robotic Process Automation (RPA), BPM acts as the strategic brain that directs automation efforts, making it a powerful example of a continuous improvement process. BPM maps the entire workflow, identifies bottlenecks, and establishes performance metrics, while RPA automates the high-volume, repetitive tasks within that framework.

This combination is crucial for scaling automation intelligently. BPM provides the governance and oversight needed to ensure you’re automating the right processes for the right reasons. It prevents the common pitfall of deploying bots to broken or inefficient workflows, which only accelerates poor outcomes.

How BPM with RPA Integration Drives Improvement

The synergy between BPM and RPA creates a structured, end-to-end improvement cycle. BPM platforms model the "as-is" state of a process, use data to pinpoint inefficiencies, and then define an optimized "to-be" state. RPA is the tactical tool used to execute the automation component of that future state, handling the rule-based tasks identified by the BPM analysis.

- Model & Analyze: Use BPM software to create detailed visual maps of existing workflows, such as invoice processing or employee onboarding. This reveals the actual process flow versus the documented one.

- Identify Automation Candidates: The process maps highlight repetitive, rule-based tasks that are prime candidates for RPA.

- Optimize & Automate: Redesign the overall process for maximum efficiency, then deploy RPA bots to execute the automated steps.

- Monitor & Control: Use the BPM system’s dashboards to track KPIs (e.g., cycle time, error rate) before and after automation to quantify the impact and identify new areas for improvement.

Actionable Takeaways for Implementation

To successfully integrate BPM and RPA, start with a clear understanding of your current processes before bringing in technology.

Strategic Insight: Treat BPM as the discovery phase for automation. Use process mining tools (a subset of BPM) to uncover the real, often messy, path that work takes through your organization. This data provides an undeniable business case for targeted RPA deployment.

- Map Before You Automate: Use BPM tools like Signavio or Celonis to create a detailed process inventory. This crucial first step provides the visibility needed to prioritize automation projects based on potential ROI.

- Target Rule-Based Bottlenecks: Focus initial RPA efforts on tasks that are high-volume, highly standardized, and prone to human error. Examples include data entry between systems, generating standard reports, or initial resume screening.

- Establish Baselines First: Before deploying a single bot, use your BPM analysis to establish clear baseline metrics for cost per transaction, cycle time, and error rates. This is essential for proving the value of your intelligent process automation solutions.

- Create a Center of Excellence (CoE): Establish a cross-functional team responsible for governing your BPM and RPA initiatives. This CoE ensures that automation efforts align with broader business goals, maintains standards, and manages the bot lifecycle.

4. Agile Operations & Iterative Deployment

Agile Operations borrows principles from software development-like sprints, continuous feedback, and rapid deployment-and applies them to operational processes. Instead of architecting a perfect, all-encompassing automation solution from the start, this approach delivers value incrementally. It allows teams to launch a minimum viable product (MVP) for an automated workflow, validate assumptions with real-world usage, and adapt based on direct user feedback.

This iterative model is a powerful continuous improvement process example because it minimizes upfront risk and accelerates time-to-value. It is particularly well-suited for AI and automation projects where the full complexity of a workflow often only becomes clear after the initial deployment. E-commerce companies, for instance, use this method to rapidly deploy recruitment automation in two-week sprints, adjusting the AI's candidate screening criteria based on real hiring outcomes.

How Agile Operations Drives Improvement

Agile Operations breaks down large, monolithic automation projects into small, manageable, and value-driven cycles. This prevents analysis paralysis and ensures that each development sprint delivers a tangible improvement to the business. The core of this method is its cyclical nature: build, measure, and learn.

- Iterative Sprints: Work is organized into short, time-boxed sprints (typically 2-4 weeks), each with a specific improvement goal.

- Continuous Feedback: Frontline users are integrated into the process, providing candid feedback during sprint reviews to guide the next iteration.

- Incremental Deployment: Solutions are deployed piece by piece, allowing the team to test, learn, and refine the automation without disrupting the entire operation.

- Adaptive Planning: The plan evolves. Metrics from each sprint directly inform the priorities and goals for the next one, ensuring resources are always focused on the highest-impact changes.

Actionable Takeaways for Implementation

To implement Agile Operations, shift your mindset from "big bang" launches to a series of small, validated steps. This approach builds momentum and ensures the final solution truly meets the needs of its users. For organizations adopting an iterative deployment model, embracing comprehensive Agile methodology best practices is fundamental to successful continuous improvement.

Strategic Insight: Use a pilot-centric model, like Red Brick Labs' 4-6 week pilot, to de-risk your first automation project. This allows you to validate the technology's effectiveness, gather essential user feedback, and build a data-backed business case for a full-scale rollout-all within a fixed, predictable timeframe.

- Define a Pilot Scope: Select a narrow, high-impact slice of a larger workflow for your first sprint. For document processing, this could mean automating the extraction of just three key fields from one specific document type.

- Measure Sprint-Level Metrics: Don't wait for the project's end to measure success. Track metrics like processing time, accuracy, or user satisfaction at the end of each sprint to make data-driven decisions for the next cycle.

- Involve End-Users Early and Often: Include the people who will actually use the automation in sprint planning and review meetings. Their ground-level insights are invaluable for identifying edge cases and usability issues.

- Plan for Multiple Iterations: Set the expectation that the first deployment is not the last. Budget and plan for 2-3 iterative cycles to refine the workflow, address feedback, and achieve the desired level of automation and efficiency.

5. Total Quality Management (TQM) & Process Standardization

Total Quality Management (TQM) is a management philosophy where every employee, from the C-suite to the front line, is committed to maintaining high standards of work in every aspect of a company's operations. It focuses on long-term success through customer satisfaction, achieved by standardizing processes, using statistical control, and fostering a culture of continuous improvement. This makes TQM a powerful foundational example of a continuous improvement process.

For organizations preparing for AI and automation, TQM is indispensable. It forces the creation of documented standard operating procedures (SOPs), quality metrics, and control points that establish a stable, predictable environment. Automation built on a standardized, high-quality process is far more reliable and effective than one layered over chaotic, inconsistent workflows.

How TQM Drives Improvement

TQM's strength comes from its holistic, organization-wide approach. It shifts the responsibility for quality from a single department to every individual, ensuring that improvement efforts are integrated and sustained across the entire value chain. The focus is on preventing defects rather than just detecting them.

- Customer Focus: All decisions and improvements are driven by the goal of increasing customer satisfaction.

- Total Employee Involvement: Every employee is empowered and trained to identify and solve quality-related problems within their sphere of influence.

- Process-Centered: TQM treats activities as processes that can be defined, measured, controlled, and improved.

- Continuous Improvement: The philosophy is built on the idea that processes can always be made better, fostering an ongoing cycle of incremental enhancements.

Actionable Takeaways for Implementation

To use TQM as a launchpad for successful automation, focus on creating a stable and documented operational foundation.

Strategic Insight: Treat process standardization as the essential "pre-flight check" before launching any automation initiative. Standardized workflows with clear quality metrics provide the perfect training data and operational rules for AI systems, dramatically reducing implementation risks and accelerating time-to-value.

- Document 'Best Practice' SOPs: Before writing a single line of code, collaborate with high-performing teams to document their most effective workflows. This creates a "golden standard" that can be used as the blueprint for both company-wide standardization and automation design.

- Define Quality at the SOP Level: Embed specific quality metrics directly into your SOPs. For a legal firm standardizing contract reviews, this could mean defining metrics for accuracy (e.g., <1% error rate in clause identification) and cycle time (e.g., <24-hour turnaround).

- Establish Clear Exception Handling: No process is perfect. Standardize the procedure for handling exceptions and edge cases. This documented protocol becomes a critical input for developers designing the logic for how an AI or automation tool should manage non-standard events.

- Use Standards as Automation Blueprints: Provide your documented SOPs and quality metrics to your automation partner or development team. This clarity ensures the automated solution accurately mimics the desired high-quality process from day one.

6. Process Mining & Data-Driven Discovery

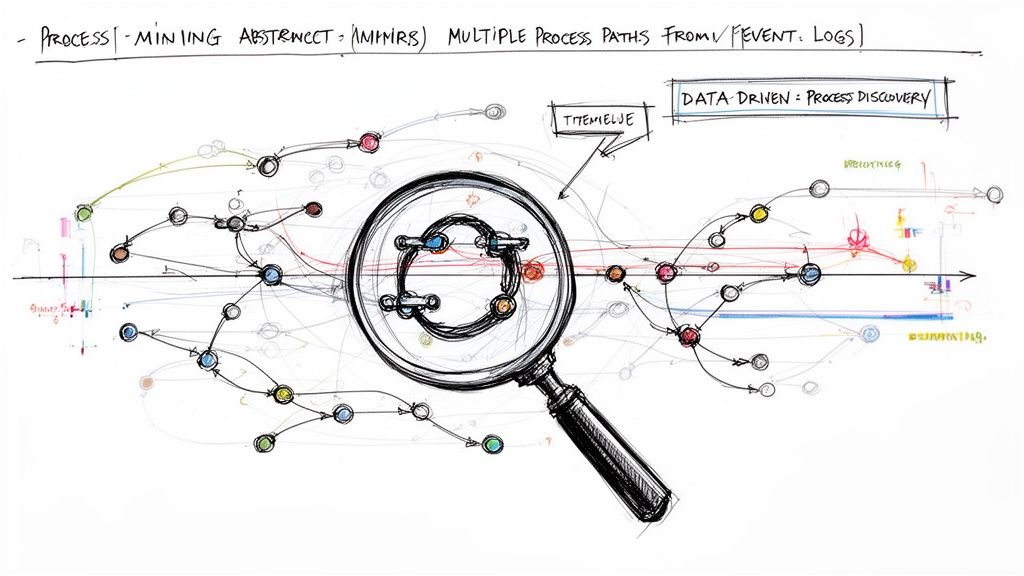

Process mining is a data science technique that acts like an X-ray for your business operations. It uses event log data from your enterprise systems (like an ERP or CRM) to automatically create a visual map of how your processes actually run, not just how you think they run. This data-driven approach moves beyond subjective interviews and static flowcharts, revealing the hidden bottlenecks, rework loops, and costly deviations that manual analysis often misses, making it an essential tool for modern continuous improvement.

For organizations looking to automate, process mining provides an objective, evidence-based starting point. It pinpoints the exact process variations and inefficiencies that are prime candidates for AI-powered solutions, ensuring you focus your automation budget on the areas with the highest potential return. Platforms like Celonis have used this to help enterprises uncover millions in savings across their procure-to-pay and order-to-cash cycles.

How Process Mining Drives Improvement

The power of process mining is its ability to reveal the "unhappy path" - the many variations and exceptions that plague a standard workflow. By visualizing every step, timestamp, and resource involved, it provides an unparalleled level of transparency into operational performance. This clarity is a cornerstone of any effective continuous improvement process.

- Discover: Automatically reconstruct and visualize the end-to-end process flow from raw event log data.

- Analyze: Use variant analysis to compare different process paths, identifying the most common, most efficient, and most problematic routes.

- Enhance: Identify root causes of delays, non-compliant steps, and rework to target specific improvements or automation opportunities.

- Monitor: Continuously track process performance against KPIs and benchmarks to ensure improvements are sustained over time.

Actionable Takeaways for Implementation

To leverage process mining for targeted automation, you must treat it as a diagnostic tool that informs your strategy.

Strategic Insight: Use process mining to replace guesswork with data. Instead of automating the "ideal" process map, automate the real-world process variations that cause the most friction and cost. This ensures your AI solution solves actual business problems from day one.

- Start with Data-Rich Processes: Target high-volume, transactional processes where your systems (ERP, CRM) already capture rich event logs. Finance (order-to-cash) and supply chain (order-to-delivery) are classic starting points.

- Focus on Conformance Checking: Use process mining to compare your actual workflows against the documented, "should-be" process. The gaps you find are immediate opportunities for targeted training, standardization, or automation.

- Combine Mining with Qualitative Discovery: While process mining shows you what is happening, it doesn't always explain why. Pair the data-driven insights from mining with a Red Brick Labs discovery process to understand the human context and design more effective automation solutions. To get a deeper understanding, explore what process mining is and how it fits into a broader improvement strategy.

- Turn Insights into Automated Actions: Connect your process mining platform to automation tools like UiPath or Automation Anywhere. This allows you to create triggers that automatically launch a bot when a specific deviation or bottleneck is detected, enabling a self-optimizing process.

7. Cycle Time Reduction & Operational Efficiency Metrics

Cycle time reduction is a continuous improvement method focused on one critical question: how can we deliver value faster? It measures the total elapsed time from the start of a process to its completion. By systematically shrinking this duration, organizations boost customer satisfaction, reduce operational costs, and increase overall throughput, making it a powerful example of a continuous improvement process.

This metric is particularly relevant for AI and automation initiatives. Technology excels at collapsing the delays inherent in manual work, such as handoffs, wait times, and data entry. Tracking cycle time provides a direct, quantifiable measure of an automation solution's impact on business velocity.

How Cycle Time Reduction Drives Improvement

Focusing on cycle time forces a holistic view of a process, exposing the hidden delays and bottlenecks that erode efficiency. Instead of optimizing individual tasks in isolation, this approach targets the entire value stream, leading to more significant and sustainable gains.

- Initiation: The moment a request is made or a task is triggered (e.g., a job application is received, a loan application is submitted).

- Processing: The "touch time" where work is actively being performed, including all manual and automated steps.

- Wait States: The idle time between steps where a task is waiting for approval, information, or resources. This is often the largest component of total cycle time.

- Completion: The final delivery of the outcome to the customer or next process step (e.g., an offer letter is sent, a loan is approved).

Actionable Takeaways for Implementation

To use cycle time as a lever for improvement, especially with automation, you must first dissect the process to find where time is truly spent.

Strategic Insight: The most significant opportunities for cycle time reduction are rarely in the "active work" phases. Instead, target the "wait states" between handoffs. AI automation is uniquely suited to eliminate these delays by instantly routing information, performing checks, and triggering the next step without human intervention.

- Map the Timeline: Use process mapping to document every step and, critically, measure the time elapsed between each one. This will visually highlight the bottlenecks and wait states where automation can have the most significant impact.

- Set Aggressive Targets: Aim for ambitious but realistic cycle time reduction goals, such as a 30-60% improvement. A financial services firm, for example, could target reducing its loan approval process from 10 days to under 48 hours.

- Track Leading and Lagging Indicators: Monitor both the end-to-end cycle time (a lagging indicator) and the smaller, contributing metrics like tasks completed per hour (a leading indicator). For more insights, you can learn how to measure operational efficiency with the right KPIs.

- Automate the Handoffs: Focus automation efforts on the points where work is passed between people or systems. An AI-powered workflow can screen a candidate's resume and automatically schedule an interview with a recruiter, eliminating days of manual coordination and delay.

8. Pilot-to-Scale Model with Continuous Optimization

The Pilot-to-Scale model is a pragmatic and powerful approach to implementing significant change, such as automation, with minimized risk. It begins with a focused, small-scale pilot project on a specific process to test assumptions, validate technology, and measure impact in a controlled environment. Based on the pilot's success, the solution is systematically scaled across the organization, incorporating lessons learned for continuous optimization. This structured rollout is a hallmark example of an iterative continuous improvement process.

This method is crucial for AI and automation initiatives, as it allows organizations to prove value and build internal confidence before committing to a massive, company-wide investment. It transforms a potentially disruptive overhaul into a managed, evidence-based evolution, ensuring each phase of expansion is more effective than the last.

How the Pilot-to-Scale Model Drives Improvement

The strength of this model lies in its de-risked, iterative nature. It avoids the "big bang" implementation failures that often plague large-scale technology projects. By starting small and learning fast, teams can refine the solution, adapt to unforeseen challenges, and build momentum for broader adoption.

- Pilot: A specific, high-impact workflow is chosen for a short-term (e.g., 4-6 week) pilot. The goal is to prove the concept and gather real-world performance data.

- Analyze & Refine: The pilot's outcomes, user feedback, and discovered process exceptions are meticulously analyzed to refine the automation logic and implementation plan.

- Scale: The proven solution is rolled out in planned phases to other teams or departments, incorporating the refinements from the pilot stage.

- Optimize: A dedicated team continuously monitors the scaled solution's performance, identifying new opportunities for enhancement and ensuring sustained gains.

Actionable Takeaways for Implementation

Adopting a Pilot-to-Scale approach requires strategic planning to ensure the initial test sets the stage for a successful enterprise-wide rollout.

Strategic Insight: Treat the pilot not just as a technology test but as a change management test. Use it to identify internal champions, understand user friction, and refine training materials. The feedback on human factors is just as valuable as the performance metrics.

- Select a Visible and Viable Pilot: Choose a pilot process with a clear ROI, engaged stakeholders, and high visibility. An early win in a respected department builds critical momentum for future phases.

- Define Clear Go/No-Go Criteria: Before starting, establish specific, measurable success metrics for the pilot. This creates an objective framework for deciding whether to scale, refine, or stop the project.

- Embrace a Structured Methodology: Partner with specialists who use a proven pilot-to-scale framework. For instance, Red Brick Labs utilizes a discovery → 4-6 week pilot → full deployment model that codifies this best practice.

- Plan the Scale in Phased Waves: Don't go from one pilot team to the entire company at once. Plan the rollout in 3-4 logical phases, allowing for transition periods and incorporating feedback from each new group of users.

8-Point Comparison of Continuous Improvement Processes

| Approach | Implementation complexity | Resource requirements | Expected outcomes | Ideal use cases | Key advantages |

|---|---|---|---|---|---|

| Lean Six Sigma | High — structured DMAIC, statistical rigor | Trained belts, analytics tools, time for projects | Quantifiable variation reduction and documented ROI | High-volume, variable processes needing statistical validation | Rigorous, measurable, scalable improvements |

| Kaizen (Continuous Improvement) | Low–Medium — cultural change and ongoing effort | Frontline engagement, leadership support, minimal tooling | Incremental, cumulative process improvements and higher engagement | Day-to-day operational frictions; grassroots automation ideas | Low-cost, builds ownership and sustainment |

| BPM with RPA Integration | Medium–High — modeling + integration work | BPM platform, RPA tools, governance and specialists | End-to-end workflow automation with monitoring and compliance | Complex workflows, legacy systems, regulated processes | Clear visualization, governance, systematic scaling |

| Agile Operations & Iterative Deployment | Medium — sprint cadence and cross-functional teams | Cross-functional teams, product owner, rapid prototyping tools | Faster time-to-value through incremental pilots and adaptation | Uncertain requirements; need for fast learning and MVPs | Rapid feedback, reduced risk, adaptable solutions |

| TQM & Process Standardization | Medium — documentation and culture adoption | SOPs, quality teams, ongoing management discipline | Consistent, standardized processes suitable for reliable automation | Regulated environments or where consistency is critical | Ensures reliable inputs for automated systems |

| Process Mining & Data-Driven Discovery | Medium–High — data extraction and analysis | Process-mining tools, clean event logs, data engineering | Objective discovery of actual flows, bottlenecks, and automation targets | Multi-system processes with available event logs | Data-driven identification of high-impact opportunities |

| Cycle Time Reduction & Efficiency Metrics | Medium — requires measurement and process changes | Timing/analytics tools, process owners, monitoring | Reduced end-to-end times, improved throughput and customer experience | Time-sensitive processes (recruitment, loan approval, order fulfillment) | Clear executive KPI; direct business impact |

| Pilot-to-Scale Model with Continuous Optimization | Medium — phased rollout and coordination | Pilot budget, change management, optimization team | Validated pilots, repeatable scaling, continuous improvement | Enterprise rollouts that must be de-risked before scaling | Minimizes risk, builds capability, enables phased scaling |

From Theory to Tangible ROI: Your Next Step in Automation

The journey through these real-world continuous improvement process examples reveals a powerful, unifying narrative. From streamlining talent acquisition with AI-powered candidate screening to automating complex financial compliance checks, the most successful initiatives share a core philosophy: they transform abstract principles into tangible, measurable business value. The era of treating continuous improvement as a theoretical exercise confined to whiteboards and strategy decks is over.

We've seen how established frameworks like Lean Six Sigma provide the statistical rigor to pinpoint waste, while a Kaizen culture empowers every team member to contribute to incremental gains. We've also explored how modern tools like Process Mining offer an unprecedented, data-backed view of how work actually gets done, moving beyond assumptions to reveal hidden bottlenecks and opportunities. These methodologies are not mutually exclusive; they are complementary tools in a modern operational leader’s arsenal.

The critical lesson is that the framework is the starting point, not the destination. True, sustainable improvement is achieved when these analytical insights are paired with intelligent automation. This is the bridge from identification to execution.

Key Strategic Takeaways for Your Organization

Reflecting on the diverse examples presented, from supply chain optimization to customer operations, several key takeaways emerge that are universally applicable for any team aiming to replicate this success:

- Start with the Problem, Not the Technology: The most impactful projects began with a clear, quantifiable business problem: "Our time-to-hire is too long," or "Document processing errors are costing us X dollars." Technology, whether RPA or a custom AI model, was the solution, not the starting point.

- Embrace the Pilot-to-Scale Model: Not a single successful example involved a massive, big-bang rollout. They all started with a well-defined pilot program focused on a specific workflow. This approach de-risks investment, proves ROI on a smaller scale, and builds internal momentum and stakeholder buy-in for broader deployment.

- Data is Your North Star: Guesswork has no place in modern continuous improvement. The consistent theme across all examples was a reliance on metrics. From establishing a baseline with process discovery to measuring outcomes like cycle time reduction and accuracy improvements, data-driven decision-making is non-negotiable.

Strategic Insight: The most advanced organizations no longer see continuous improvement and automation as separate functions. Instead, they view them as a single, integrated "improvement engine" where data from automated processes continuously feeds back into the discovery loop, creating a virtuous cycle of optimization.

Your Actionable Path Forward

Moving from inspiration to implementation is the most crucial step. The examples in this article provide a blueprint, but your organization's journey will be unique. The path forward involves a clear, methodical approach that mirrors the successes we've analyzed.

- Identify Your Top Candidate Process: Which manual, repetitive, or error-prone process causes the most friction for your team or customers? Use the frameworks discussed, like Value Stream Mapping or Process Mining, to identify a high-impact, low-complexity starting point.

- Quantify the Opportunity: Before building anything, define what success looks like. Calculate the current cost in terms of employee hours, error rates, or delays. This baseline is essential for proving the ROI of your future pilot program.

- Launch a Focused Pilot: Partner with a specialized team to design and deploy a small-scale automation pilot. The goal is not perfection but to quickly validate the solution's potential and gather real-world data within a matter of weeks, not months.

Mastering this cycle of discovery, piloting, and scaling is no longer a competitive advantage; it is a fundamental requirement for operational excellence and sustainable growth in today's fast-paced digital landscape.

Ready to turn your continuous improvement goals into a concrete, ROI-driven project? The experts at Red Brick Labs specialize in rapidly identifying high-value automation opportunities and building custom AI-powered pilot programs in just 4-6 weeks. Schedule a discovery call to map your process and build a business case for intelligent automation today. Learn more at Red Brick Labs.