Let’s be honest—most companies think they know how their business runs. There are process maps, flowcharts, and established procedures that lay out the “official” way things are supposed to get done. But the reality on the ground? It’s almost always a different story.

Process mining is what bridges that gap. It’s a data-driven discipline that uses the digital footprints left behind in your IT systems to create a living, breathing map of how your business processes actually work. Forget the idealized flowcharts. This is the unvarnished truth, showing every detour, bottleneck, and workaround.

Think of it like having a complete game replay from every player's perspective, instead of just staring at the final scoreboard. You see every move, every fumble, and every brilliant play as it happened.

Uncovering the Reality of Your Operations

The "official" process map might show a clean, straight line from A to B. But in the real world, that path is often a tangled mess of unexpected loops, manual interventions, and frustrating delays that quietly drain your resources.

This is where process mining shines. It digs into your event logs—the digital breadcrumbs left by every single action in systems like your CRM, ERP, or HR platform. By analyzing these timestamps, user IDs, and activity logs, it automatically pieces together a visual, interactive model of your end-to-end operations.

Suddenly, you have a single source of truth that reveals every variation and deviation from the norm, replacing assumptions with cold, hard facts.

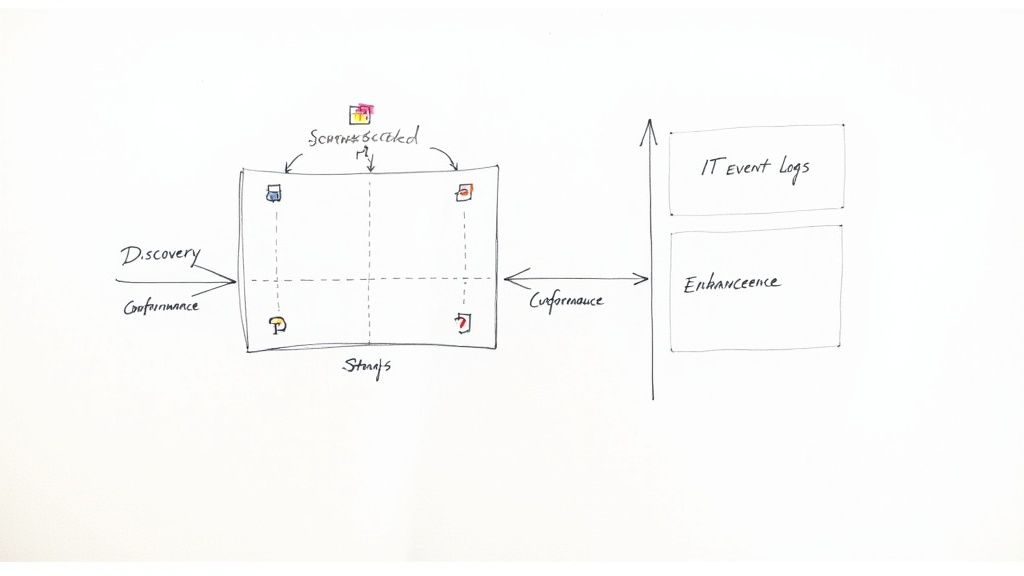

The Three Core Pillars of Process Mining

Process mining technology is built on three fundamental capabilities. Each one addresses a critical question about your operations, moving you from simply seeing what’s wrong to knowing exactly how to fix it. Understanding these pillars is the first step to unlocking its power.

To make this simple, here’s a quick overview of how each pillar functions and the goal it serves.

| Pillar | Primary Goal | Key Question It Answers |

|---|---|---|

| Discovery | Visualize the actual process | "What is really happening in my organization?" |

| Conformance | Compare reality to the ideal | "Are we following the rules and procedures we set?" |

| Enhancement | Identify and act on improvements | "Where can we optimize, automate, or redesign for better results?" |

Together, these three pillars form a continuous improvement loop, allowing you to not only diagnose issues but also to validate the impact of your changes over time.

Process mining is a discipline that combines data science with process management to help organizations become more efficient and effective. It's about finding the story behind the data to drive meaningful business improvement.

The incredible value here is why the global process mining market is exploding. Projections show it rocketing from around USD 470.77 million to a staggering USD 9.35 billion by 2032—that’s a compound annual growth rate of roughly 45.3%. This isn't just hype; it reflects a massive shift toward data-driven transparency and optimization.

Process mining is an advanced technique that fits within a broader family of data tools. To see where it fits in the larger picture, check out this comprehensive guide to business intelligence and reporting.

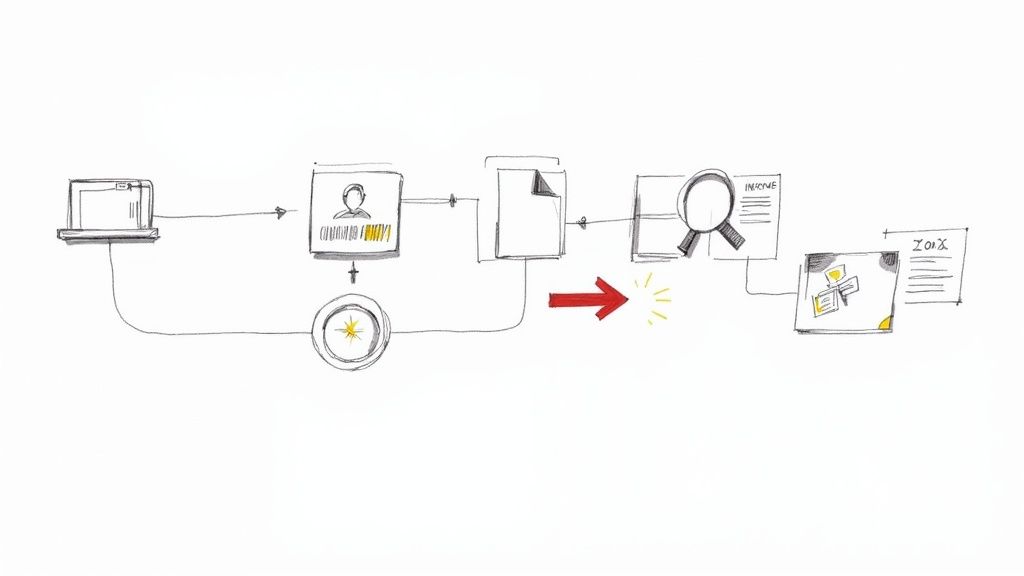

How Process Mining Actually Works

So, how does this technology go from a mountain of raw data to a crystal-clear picture of your business? It’s not magic—it's a surprisingly logical, three-part method that reveals, checks, and improves how work gets done. The entire discipline is built on one simple thing: event logs.

Think of event logs as the digital breadcrumbs that every single action leaves behind in your company's systems. From SAP to Salesforce, every time an employee or system does something, it gets recorded.

Each of these digital footprints contains three key ingredients:

- A unique Case ID (like an invoice number or a customer support ticket).

- An Activity (what happened, like "Invoice Approved").

- A Timestamp (exactly when it happened).

With just these three pieces of information, process mining software stitches together millions of events to give you an unbiased, step-by-step replay of every process in your organization.

To make this real, let’s walk through a classic business scenario: the order-to-cash process. It’s the perfect example because it spans multiple teams and systems, making it a prime spot for hidden delays and costly mistakes.

Step 1: Process Discovery

First up is Process Discovery. This is where the magic starts. The software automatically ingests all those event logs and builds a visual process map. It's like creating a perfect Google Maps traffic view of your operations—you don't just see the main highways you designed, you see every shortcut, traffic jam, and bizarre detour that people actually take.

This isn’t some idealized flowchart drawn on a whiteboard. It’s the ground truth, backed by 100% of your data. It shows you the most common path, sure, but more importantly, it uncovers all the exceptions.

For our order-to-cash example, discovery might reveal that 25% of all orders get stuck in a rework loop where the finance team has to manually fix data entry errors. That’s a bottleneck nobody even knew existed because it wasn’t in any official documentation. This objective view is the foundation for everything that follows.

Step 2: Conformance Checking

Once you have that real-world map, you move on to Conformance Checking. Think of this as an automated audit. It takes the process map you just discovered and compares it against your ideal, "by-the-book" process model. This is where you measure reality against the rules.

You feed the software your official workflow—the way things should happen—and it instantly highlights every single deviation. Every skipped step, policy violation, and compliance breach gets flagged.

Conformance checking finally answers the question, "Are we actually following our own procedures?" It turns compliance from a manual spot-check into a continuous, data-driven activity.

Looking at our order-to-cash process, conformance checking might expose some serious issues:

- Skipped Approvals: It might show sales reps are bypassing the mandatory credit check for big clients to close deals faster, exposing the company to financial risk.

- Sequence Errors: The data could reveal that goods are frequently shipped before payment is confirmed, directly violating company policy.

- Unauthorized Discounts: It could flag every instance where a discount over the approved limit was given without the required manager sign-off.

Each of these deviations is a risk, a hidden cost, or a revenue leak that was completely invisible before.

Step 3: Process Enhancement

The final step, Enhancement, is where you turn all these insights into action. Armed with the "what" from discovery and the "why" from conformance checking, you can now fix the root cause of the problems.

This isn't about guesswork. Modern process mining tools use the data to pinpoint the highest-impact improvements. You can model potential changes—like automating a specific step—and simulate the outcome to see the projected ROI before you commit a single dollar or developer hour.

Based on our order-to-cash findings, the enhancement phase would deliver a clear action plan:

- Automate Credit Checks: The data proves manual checks are a bottleneck. The system would recommend automating approvals for all orders under $5,000.

- Redesign the Order Form: To eliminate the rework loop, the tool might suggest adding mandatory fields to the order entry screen, ensuring all data is correct from the start.

- Trigger Real-Time Alerts: To stop unauthorized discounts, the software could recommend setting up an automated alert that notifies a manager the moment a rep enters a non-compliant discount.

This three-step cycle of discovery, conformance, and enhancement creates a powerful engine for continuous improvement. You finally get the clarity to see what's really happening, the evidence to understand why, and the roadmap to fix it for good.

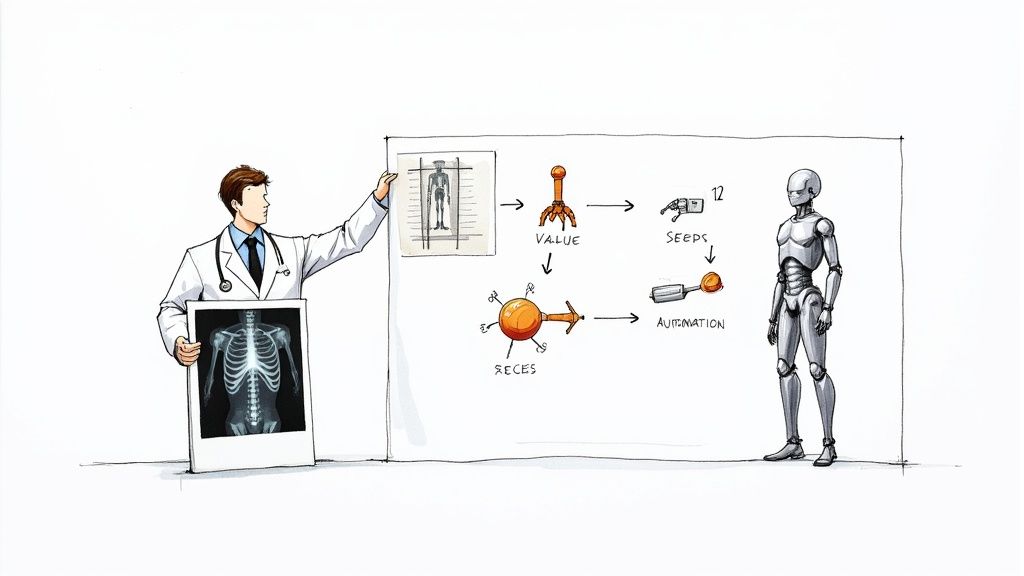

The Power of Process Mining in Intelligent Automation

Trying to automate your business without first understanding your processes is like a surgeon operating without an X-ray. You might have a vague idea of where the problem is, but you're missing the detailed, data-driven picture needed to actually fix it. This is exactly why process mining is the critical first step for any serious automation initiative.

It gives you the real blueprint, showing how your workflows actually run day-to-day—not just how they look on a tidy flowchart. Automating a process without this insight is a massive gamble. You risk pouring money and time into making a broken, inefficient, or redundant workflow run faster, which only magnifies the original problem.

Process mining flips this on its head. It turns a speculative bet on automation into a strategic, measurable project grounded in hard data.

Identifying High-Value Automation Opportunities

One of the biggest questions in any automation program is simply, "Where do we start?" Process mining takes the guesswork out of the equation. It shines a spotlight on the most repetitive, time-consuming, and rule-based tasks that are perfect candidates for automation.

By digging into event logs, the software can quantify the real impact of manual work and bottlenecks. For example, it might uncover that the accounts payable team spends 40% of its time just manually matching invoice details with purchase orders. This isn't a hunch from a manager; it's a hard metric you can bring to the leadership team.

These data-backed insights let you prioritize automation projects based on their potential for the highest return on investment (ROI). You can focus your efforts where they’ll make the biggest impact, a core concept we explore in our guide on what is intelligent automation.

Predicting and Measuring Automation ROI

Before you even deploy a single bot, process mining lets you simulate the impact of automation. You can create a model that shows what would happen to a workflow if a specific task were automated, giving you a clear forecast of the expected benefits.

This simulation might predict that automating invoice matching could:

- Slash the average invoice processing time from 5 days to just 4 hours.

- Cut down on manual errors by an incredible 95%.

- Free up 25 hours per week for the finance team to focus on more strategic work.

By providing a data-driven business case, process mining helps secure stakeholder buy-in and sets clear expectations for success. It shifts the conversation from "we think this will help" to "our data shows this will save X amount of dollars and Y amount of hours."

And it doesn't stop there. Once automation is live, process mining continues to monitor performance. It keeps an eye on how your digital workers are interacting with systems, making sure they’re performing as expected and delivering the promised ROI. This creates a powerful, continuous feedback loop for ongoing optimization.

A Foundation for Scalable Automation

As companies grow, so does the complexity of their processes. Integrating process mining with AI and machine learning is making it even better at handling this complexity through predictive analytics and real-time monitoring. This combination is essential for organizations that need strict audit trails and want to drive down operational costs—which is why it's seeing huge adoption in finance, manufacturing, and other industries.

Tools like the Freshservice Workflow Automator are built to streamline IT processes, and they benefit immensely when process mining is used first to ensure automation is applied where it's needed most. By building on a clear, data-verified understanding of your current workflows, process mining provides the solid ground you need to build a successful and scalable intelligent automation program across your entire organization.

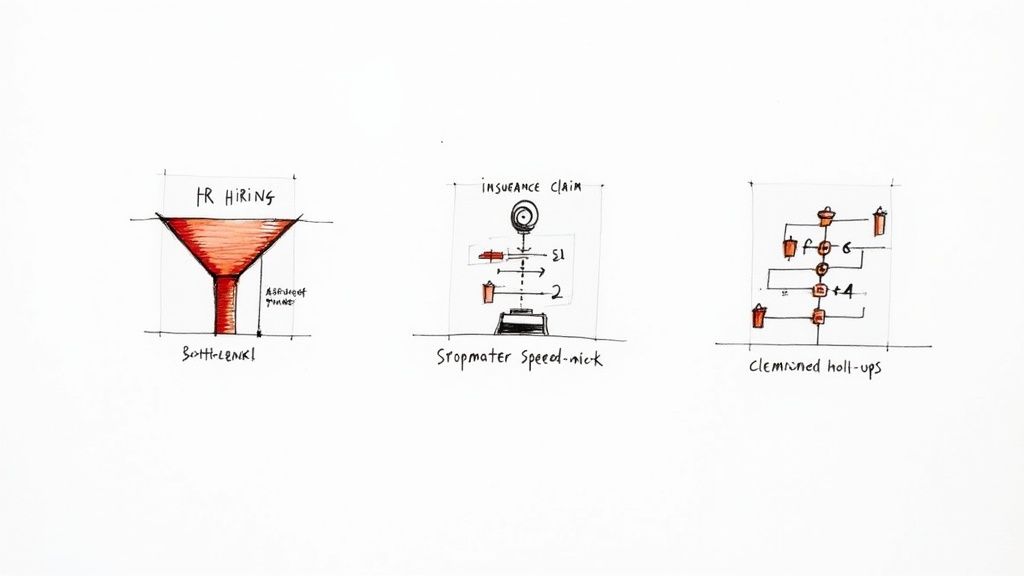

Real World Process Mining Use Cases

Theory is great, but seeing how process mining solves real, tangible business problems is where the rubber meets the road. This isn't just about generating fancy diagrams; it's about delivering measurable results that cut costs, delight customers, and make your teams more effective.

Let's move past the abstract and dive into a few stories of how companies used process mining to diagnose and fix critical operational headaches. Each example is a mini case study: the problem they were stuck with, the "aha!" moment they found in the data, and the powerful results they achieved.

These are the kinds of transformations that happen when you stop guessing and start seeing what's really going on inside your business.

Streamlining HR and Recruiting Pipelines

A fast-growing tech company had a serious problem: they were losing top talent during the hiring process. On paper, their workflow looked fine, but candidates were dropping out left and right. The HR team had a hunch it was slow manager approvals, but they were relying on gut feelings and anecdotes.

So, they connected process mining software to their Applicant Tracking System (ATS) and let the data tell the real story. The insights were immediate and completely unexpected. The problem wasn't the managers at all.

- The Black Hole of Screening: The process map revealed that applications from top job boards were sitting untouched for an average of seven days before a recruiter even looked at them. In a competitive market, that’s an eternity. The best candidates were already accepting other offers.

- The Scheduling Nightmare: Another massive bottleneck popped up during interview scheduling. The endless email chains between recruiters, candidates, and hiring managers created an average scheduling delay of nine days. It was a terrible experience for everyone involved.

Armed with this objective data, the company made a couple of smart, targeted changes. They automated alerts for recruiters when high-priority applications landed and rolled out a scheduling tool that let candidates book slots directly. Simple, right? But the impact was huge.

Outcome: The company slashed its average time-to-hire by 40%, dropping from 45 days to just 27. Even better, their offer acceptance rate for top candidates shot up by 25% the very next quarter, giving them a massive leg up in the talent war.

Optimizing Insurance Claims Processing

An established insurance carrier was getting squeezed by rising operational costs and sinking customer satisfaction scores. Their claims process was a complete black box, bogged down by manual handoffs and endless rework. They knew things were broken but couldn't see exactly where or why.

By applying process mining to their claims management system, they mapped out every single step, from the first notice of loss to the final payment. The visual map instantly lit up several huge areas of waste that went against their own official policies.

- Needless Manual Reviews: The data showed that a shocking 30% of all low-value claims (under $1,000) were being manually reviewed by three different adjusters, even though company policy only required one. This one deviation was costing them thousands of work hours every year.

- The "Ping-Pong" Effect: The analysis also uncovered that adjusters were repeatedly sending requests for the same information back to customers. This constant back-and-forth was driving customers crazy and was the number one source of complaints.

With indisputable proof of where the process was failing, the insurer took decisive action. They automated the approval for all claims under a certain dollar amount and redesigned their customer communication templates to make sure they got all the required info on the first try.

Fixing Supply Chain and Payment Delays

A large manufacturer was damaging key supplier relationships because of chronic late payments. Their procure-to-pay process was a tangled mess, spread across procurement software, their ERP, and other systems, making it impossible to get a clear end-to-end view.

Process mining was the key to stitching all that disparate data together into one unified picture. And what it revealed completely debunked the finance team's long-held belief that suppliers were just submitting invoices wrong.

The real culprit was a hidden bottleneck buried deep inside their own operations. The data clearly showed that invoices were getting stuck waiting for a "goods receipt" confirmation from the warehouse team. This step was supposed to be instant, but it was often delayed by days, freezing the entire payment workflow.

This insight allowed them to fix the actual root cause. They equipped the warehouse with a mobile scanning system to log deliveries in real-time. This simple change ensured the goods receipt was confirmed instantly, which unlocked the invoice for immediate processing by accounts payable. The result? They dramatically improved their on-time payment rate, repaired supplier relationships, and even managed to negotiate better terms.

Your Roadmap to Implementing Process Mining

So, you're ready to get started with process mining? It can feel like a massive undertaking, but the secret is to treat it like any other major business initiative: start small, prove the value, and then build on your success.

Think of it this way—you wouldn't try to renovate an entire house at once. You’d start with one room, get it right, and use that win to fuel the rest of the project. The same logic applies here. We’re going to walk through a roadmap that turns a complex idea into a series of clear, manageable steps.

Start With a High-Impact Pilot Project

Everything hinges on the success of your first project. Forget boiling the ocean. Your goal is to run a tight, focused pilot that solves a real, painful problem and gets people excited about what’s possible.

Look for a process that’s both critical to the business and notoriously clunky. Great candidates are often found in areas like order-to-cash, procure-to-pay, or even IT service management because they are usually rich with data and their inefficiencies are felt across the company.

Don't move forward without a rock-solid business case. You need to frame the problem with specifics. Instead of saying, "We want to improve procurement," say, "Our goal is to reduce late supplier payments by 50%." This gives you a clear target and makes it easy to measure success.

Your first project should run in a tight, 4–6 week cycle. This isn't an arbitrary timeline. It creates urgency, delivers tangible results before anyone loses interest, and shows executive sponsors a quick return on their support.

Select the Right Tools and Partners

With a pilot project defined, it's time to find the right software. The market is crowded, but you can cut through the noise by focusing on what your team actually needs. How easily can the tool plug into your core systems, like SAP or Salesforce? Is the interface intuitive enough for a business analyst, or does it require a data scientist to make sense of it?

But remember, you're not just buying software; you're investing in a partnership. A great vendor will do more than just sell you a license. They'll act as a guide, sharing best practices from hundreds of other implementations and helping you sidestep common roadblocks. The best tools bridge the gap between insight and action, which is the cornerstone of any successful process automation solution.

To help you navigate this, here are the key criteria to keep in mind when talking to vendors.

Process Mining Vendor Evaluation Checklist

Choosing the right partner is critical. This checklist breaks down what to look for beyond just the features list, focusing on what will actually drive success in your organization.

| Evaluation Criteria | Why It Matters | Questions to Ask |

|---|---|---|

| Data Connectivity | If the tool can't easily access your data, the project is dead on arrival. | What pre-built connectors do you have for our key systems (SAP, Oracle, Salesforce)? How complex is it to connect to custom or legacy systems? |

| User Experience (UX) | The tool should empower business users, not just data scientists. | Can we get a live demo with our own data? How intuitive is the process mapping and analysis interface for a non-technical user? |

| Actionability & Integration | Insights are useless without a clear path to action. | How does your platform help us move from analysis to improvement? Can it trigger automated workflows or integrate with RPA/BPM tools? |

| Scalability & Performance | Your pilot may be small, but your ambition isn't. The platform must handle enterprise-level data volumes. | What is the largest data set one of your clients is currently analyzing? How does the performance hold up with billions of events? |

| Vendor Support & Expertise | A good partner accelerates your learning curve and helps you avoid common mistakes. | What does your onboarding process look like? Do you offer strategic consulting or just technical support? Can we speak to a current customer in our industry? |

| Total Cost of Ownership | Look beyond the license fee to understand the full investment required. | What is your pricing model (per user, per process, data volume)? Are training, support, and implementation services included or extra? |

Using a structured evaluation like this ensures you pick a partner that fits not just your pilot project, but your long-term vision for a more efficient, data-driven enterprise.

Execute and Scale Your Initiative

Once you’ve knocked your pilot project out of the park and demonstrated a clear ROI, it’s time to scale. This is the crucial leap from running a cool project to building a true organizational capability. The most effective way to do this is by establishing a Center of Excellence (CoE).

Think of the CoE as the central nervous system for all things process improvement. This dedicated team is responsible for:

- Standardizing Best Practices: They create the playbook. This ensures every department uses a consistent, effective approach for data extraction, analysis, and project management.

- Training and Enablement: They’re the internal evangelists, equipping business teams with the skills to use process mining tools themselves. This fosters a culture where everyone is empowered to improve their own workflows.

- Managing a Portfolio of Projects: The CoE maintains a pipeline of potential initiatives, prioritizing them based on strategic value and ensuring resources are always aimed at the biggest opportunities.

By building this internal muscle, process mining stops being a niche tool for a handful of analysts. It becomes the standard way your organization understands, measures, and refines how work gets done, driving continuous improvement long after that first pilot is a distant memory.

Navigating Challenges and Measuring Your Success

Bringing any new technology into a business has its share of speed bumps, and process mining is no exception. A successful launch isn't just about picking the right software; it’s about having a smart plan to handle common obstacles and a laser focus on showing real, measurable results that get leadership's attention.

The journey usually starts with a couple of familiar challenges. First, getting clean, trustworthy data out of different IT systems can be a real headache. Then there’s the human element—you have to get everyone from department heads to the people on the front lines excited about a new way of working. Managing that change is every bit as crucial as the tech itself.

Overcoming Common Process Mining Hurdles

The best way to deal with these challenges is to see them coming. If you're proactive, you can turn what might have been a major roadblock into a minor detour on your way to success.

Here are a few practical ways to handle the most common issues:

- Poor Data Quality: Don't try to boil the ocean. For your pilot project, pick a single process with a reliable data source. Instead of connecting everything at once, find one area where the data is relatively clean. This helps you build momentum and show value fast.

- Lack of Stakeholder Buy-In: Nobody gets excited about "process mining." They get excited about solving their problems. Frame it in their terms. Show the finance team how you can cut down on late payment fees. Help the sales team see exactly what’s holding up customer orders.

- Resistance to Change: Get employees involved from day one. This isn't about pointing fingers or finding fault. Position process mining as a tool to get rid of frustrating, repetitive tasks and make everyone's job a little bit easier.

The goal is to build a coalition of supporters who see process mining as an essential tool for operational efficiency improvement. When people understand how it helps them win, they become your biggest champions. You can explore more strategies in our guide to improving operational efficiency.

Measuring What Matters: Key Performance Indicators

Once you’re up and running, the game shifts to proving the project's worth. Leadership needs to see a clear return on investment (ROI), and that means you have to track the right Key Performance Indicators (KPIs). The great thing about process mining is that it makes measuring this impact incredibly direct.

You’ll want a mix of hard numbers and those all-important qualitative wins.

Quantitative KPIs (Hard Metrics):

- Cycle Time Reduction: This is a big one. Measure the drop in the average time it takes to get something done, like going from a customer's order to cash in the bank. A 15% reduction in cycle time is a result that gets noticed.

- Cost Savings: Tally up the money saved by cutting out manual rework, getting rid of pointless steps, or grabbing early payment discounts you used to miss.

- Automation Rate: Keep track of the percentage of tasks or cases that can now run entirely on their own, without anyone having to touch them.

Qualitative KPIs (Soft Wins):

- Compliance Improvement: Show a clear reduction in policy violations, like skipped approval steps that used to be common.

- Employee Satisfaction: Check in with the teams. Has removing those frustrating bottlenecks made their day-to-day work better? A quick survey can tell you a lot.

- Customer Satisfaction (CSAT): Connect the dots between faster processing times and happier customers. Higher CSAT scores are a powerful indicator of success.

This balanced approach lets you tell the full story of your success and makes the case for future investment. And that kind of transparency is exactly why the process mining software market is projected to hit an incredible USD 71.41 billion by 2033. You can dig into the numbers in the full process mining software market report.

By getting ahead of those initial hurdles and zeroing in on these critical metrics, you can turn process mining from a promising idea into a proven engine for business value.

Frequently Asked questions about process mining

Even with a clear plan, a few questions always pop up. Let's tackle some of the most common ones we hear from leaders who are just starting to explore process mining.

How Is Process Mining Different From Business Intelligence?

This is a fantastic and very common question. Think of it this way: Business Intelligence (BI) gives you the scoreboard, while process mining gives you the game tape.

Business Intelligence (BI) is all about the 'what'. Your BI dashboards are great at tracking high-level metrics and KPIs. For instance, a BI report might tell you that your on-time delivery rate dropped to 85% last month. It flags the problem, but it doesn't tell you why it happened.

Process mining, on the other hand, digs into the 'how' and 'why'. It doesn't just show you the final score; it replays every single move that led to it. A process mining tool would visualize every step in your delivery process and pinpoint the exact reason for the drop. You might discover that 30% of orders are getting stuck in manual credit checks, creating a bottleneck that delays every subsequent step.

BI shows you the symptom. Process mining diagnoses the root cause.

What Skills Does My Team Need for Process Mining?

You don't need to go out and hire a team of data scientists to get this off the ground. Modern process mining platforms are built for business users, with visual, intuitive interfaces that don't require a PhD in statistics to understand.

The most effective teams we've seen have a powerful combination of two key roles:

- A business process expert—someone who lives and breathes the workflow, like a senior accounts payable clerk or a seasoned HR manager.

- A data-savvy analyst—someone who is comfortable navigating IT systems and knows how to pull the required event logs.

This pairing is magic. The process expert provides the real-world context to make sense of what the software reveals, while the analyst ensures the data feeding it is clean and accurate. Together, they can turn digital insights into a concrete action plan.

Can I Use Process Mining for Any Business Process?

Process mining is incredibly versatile, but it does have one non-negotiable requirement: the process must leave a digital footprint.

If your workflow runs entirely on sticky notes, hallway conversations, and gut feelings, there won't be any event log data to analyze.

Luckily, almost every critical business process today runs through one or more digital systems. This makes process mining a perfect fit for digging into and improving a huge range of operations. We often see it applied to:

- Order-to-Cash (O2C): Following the entire journey from the moment a customer places an order until the cash is in the bank.

- Procure-to-Pay (P2P): Analyzing everything from a purchase request all the way to the final supplier payment.

- IT Service Management (ITSM): Visualizing the complete lifecycle of support tickets to slash resolution times.

- Recruiting and Onboarding: Mapping the entire candidate journey to find and eliminate the bottlenecks that are costing you top talent.

The rule of thumb is simple: if the steps are recorded in your ERP, CRM, or another core business application, you can almost certainly use process mining to make it faster, cheaper, and more efficient.

Ready to stop guessing and start seeing exactly how your business runs? At Red Brick Labs, we design and build AI-powered automation solutions that turn insights into measurable results. Schedule a free consultation to discover your highest-impact automation opportunities.