Process automation solutions are simply systems that use technology to handle repetitive, rule-based work so your team doesn't have to. Think of them as a digital workforce that can take on everything from mind-numbing data entry to more complex, multi-step workflows, freeing up your people to focus on work that actually requires a human brain.

What Are Process Automation Solutions?

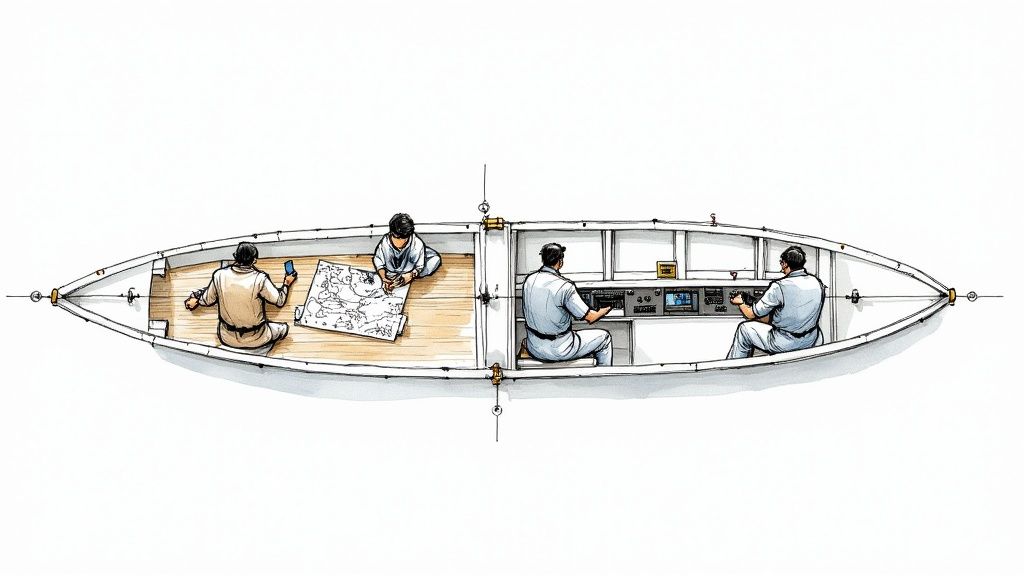

Imagine your company is a ship at sea. Running it with manual processes is like trying to navigate with old paper maps and a compass. It gets the job done, sure, but it's slow, tedious, and things can go wrong fast when a storm hits.

Process automation is your modern GPS and autopilot. It doesn’t just point to the destination; it calculates the fastest route, adjusts for changing weather in real-time, and handles the moment-to-moment steering. This lets your crew—your actual experts—focus on the bigger picture: navigating tricky waters, managing the cargo, and charting the next big voyage. They're no longer bogged down just trying to stay on course.

The Core Purpose of Automation

At its heart, automation is about building a business that runs more efficiently, with fewer errors, and can handle growth without breaking a sweat. When you take the manual grunt work off your team's plate, you accomplish a few critical things:

- Increased Efficiency: Bots and automated systems can execute tasks way faster and more consistently than any human, and they do it 24/7 without needing a coffee break.

- Reduced Errors: By eliminating manual data entry and other human touchpoints, you slash the risk of those small, costly mistakes that always seem to creep in.

- Enhanced Scalability: Your business can suddenly handle a huge spike in orders or customer requests without having to proportionally increase your headcount.

This isn't just a niche idea; it's becoming standard practice. The global process automation market is on track to hit USD 96.33 billion in 2025 and is expected to rocket past USD 170.89 billion by 2035. That kind of growth tells you everything you need to know about where modern business is headed.

Process automation isn’t about replacing people. It’s about augmenting them. It’s about shifting your most valuable asset—your team’s talent—from low-value repetition to high-impact problem-solving where they can truly shine.

From Simple Tasks to Intelligent Workflows

Automation isn't an all-or-nothing game. It exists on a spectrum.

On one end, you have simple, linear tasks. Think copying customer info from a spreadsheet into your CRM. This is where most companies dip their toes in the water, often using straightforward tools. A great starting point is understanding no-code automation, which lets non-technical teams build these workflows themselves.

But on the other end of the spectrum, you have truly intelligent workflows that juggle multiple systems and make decisions on their own. For example, an advanced system could grab a vendor invoice from an email, pull out the key data, check it against a PO in your accounting software, approve the payment, and file the document away—all without a single person lifting a finger.

This guide will walk you through the technologies that make this entire range possible, from the simple to the sophisticated.

Understanding Core Automation Technologies

To really see what process automation can do, you have to look under the hood. A great automation solution isn't just one single piece of software; it's a team of specialized technologies working together. Each one has a specific job, and when you combine them, they can solve just about any business problem you throw at them.

Let's break down the four key players in any modern automation toolkit.

Robotic Process Automation: The Digital Workforce

Think of Robotic Process Automation (RPA) as your digital workforce. These are software "bots" built to perfectly copy the repetitive, rule-based tasks a human does on a computer. They click, type, copy, and paste just like a person, only they do it much faster and never get tired or make typos.

RPA is the reliable workhorse of automation, perfect for predictable, high-volume work.

For example, picture an HR assistant spending two hours every morning moving new hire data from a spreadsheet into three different systems: payroll, benefits, and the company directory. An RPA bot can do that entire job in less than five minutes, every single time, without anyone needing to watch over it.

This is where many automation journeys start—handling the grunt work of structured data and straightforward workflows.

Intelligent Document Processing: The Digital Eyes

RPA is great with neat, organized data, but most businesses are drowning in messy documents like invoices, contracts, and purchase orders. This is where Intelligent Document Processing (IDP) steps in. Think of IDP as the "digital eyes" of your automation system.

It uses AI and computer vision to read, understand, and pull specific information from any document, whether it’s a crisp PDF or a scanned, crumpled form. It can find an invoice number, grab the total amount due, and even figure out what kind of document it’s looking at all on its own.

By automating document-heavy processes, companies often slash processing times from days down to minutes. This doesn't just speed things up; it frees up your skilled people to focus on analyzing information and solving problems instead of mind-numbing data entry.

IDP is the essential bridge that turns chaotic, unstructured information into clean, useful data that your other automation tools can work with.

Generative AI and LLMs: The Digital Brain

If RPA gives your system hands and IDP gives it eyes, then Generative AI and Large Language Models (LLMs) give it a brain. These technologies bring the power to understand context, make judgments, and even create new content from scratch.

Unlike an RPA bot that just follows a script, an LLM can handle nuance. It can read a customer email and understand if they’re happy or frustrated, summarize a 50-page legal contract into a few bullet points, or draft a personalized reply to a client’s question. This adds a layer of intelligence that was missing from automation in the past. To see how this works in more detail, check out our guide on what is intelligent automation.

This kind of intelligence is why the process automation market is booming. Valued at USD 15.2 billion in 2024, the market is projected to grow at a CAGR of 14.3% through 2034. It’s clear that businesses are betting big on AI to get more efficient and perform better. You can dig into the numbers on this expanding market and its drivers at gminsights.com.

AI Agents: The Digital Conductor

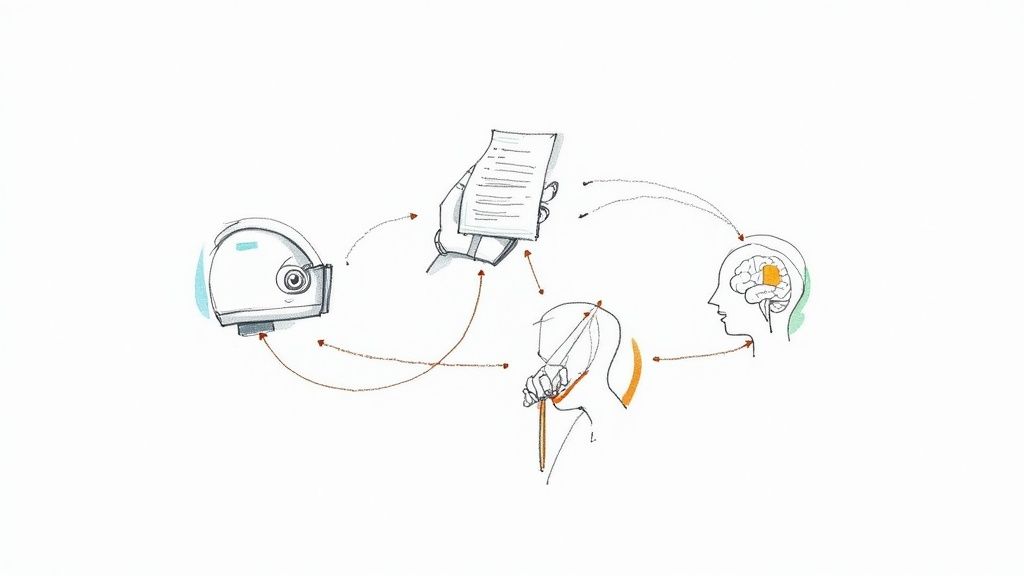

Finally, AI Agents are the conductors that orchestrate the entire symphony. An agent is a smart, autonomous system that can use all the other tools—RPA, IDP, and LLMs—to carry out complex, end-to-end processes. It can think, plan, and act to hit a specific goal.

Instead of just doing one task, an AI agent can manage a whole workflow.

Let's see how it all comes together in a real-world supply chain scenario. An AI agent is given the goal: "Resolve supplier shipment delays."

- It starts by using an LLM to read and understand an email from a supplier about a shipping delay.

- Then, it uses IDP to scan an attached packing slip and extract the purchase order number.

- Next, it calls on an RPA bot to log into the ERP system, find the order, and check current inventory levels for that product.

- Finally, the agent uses the LLM again to write a reply to the supplier and an internal alert for the logistics team, outlining a plan to manage the shortage.

This ability to coordinate different tools is what makes modern automation so powerful. It’s not about just automating single clicks anymore; it’s about giving an entire business function an intelligent, autonomous assistant.

To make these concepts even clearer, here’s a quick comparison of how each technology fits into the bigger picture.

Comparison of Core Automation Technologies

| Technology | Primary Function | Example Use Case | Complexity Level |

|---|---|---|---|

| Robotic Process Automation (RPA) | Mimics human actions to execute rule-based tasks on a computer. | Copying data from a spreadsheet and pasting it into a CRM system. | Low to Medium |

| Intelligent Document Processing (IDP) | Extracts and classifies data from structured and unstructured documents. | Reading invoices to extract vendor names, dates, and line items. | Medium |

| Generative AI & LLMs | Understands, summarizes, and generates human-like text and content. | Drafting personalized email responses to customer support tickets. | High |

| AI Agents | Orchestrates multiple tools (RPA, IDP, LLMs) to manage complex workflows. | Managing the entire accounts payable process, from invoice receipt to payment. | Very High |

As you can see, each technology has a distinct role. While powerful on their own, their true potential is unlocked when they work together as part of a comprehensive process automation solution.

How to Measure the Real Impact of Automation

So, you’ve implemented new process automation solutions. That’s great. But how do you actually prove they’re working? The real key is moving past vague feelings of improvement and getting down to the hard numbers. You need to measure the tangible business outcomes.

This means looking at both the financial figures on your balance sheet and the operational gains in your day-to-day work. A solid measurement framework does more than just justify the initial spend—it builds an undeniable case for expanding automation across the company.

Calculating Your Return on Investment

Let’s start with the one metric every CFO wants to see: Return on Investment (ROI). It’s the ultimate proof that your automation efforts are creating more value than they cost. And calculating it doesn’t have to be a complicated affair.

Think of it as a straightforward cost-benefit analysis. On one side, you have your total investment—software licenses, implementation fees, and any internal hours spent on the project. On the other, you have the value you’ve gained, which almost always starts with reclaimed employee hours.

Here’s a simple way to break it down:

- Calculate Reclaimed Hours: Figure out how many hours a week a specific manual process eats up.

- Assign a Value: Multiply those hours by the fully-loaded hourly cost of the employee doing that task.

- Project Annual Savings: Take that weekly savings number and multiply it by 52.

When you stack those annual savings up against your initial and ongoing costs, you get a crystal-clear picture of your ROI. This simple math turns an abstract idea like "time savings" into a concrete dollar amount that speaks directly to the bottom line.

Moving Beyond ROI with Key Performance Indicators

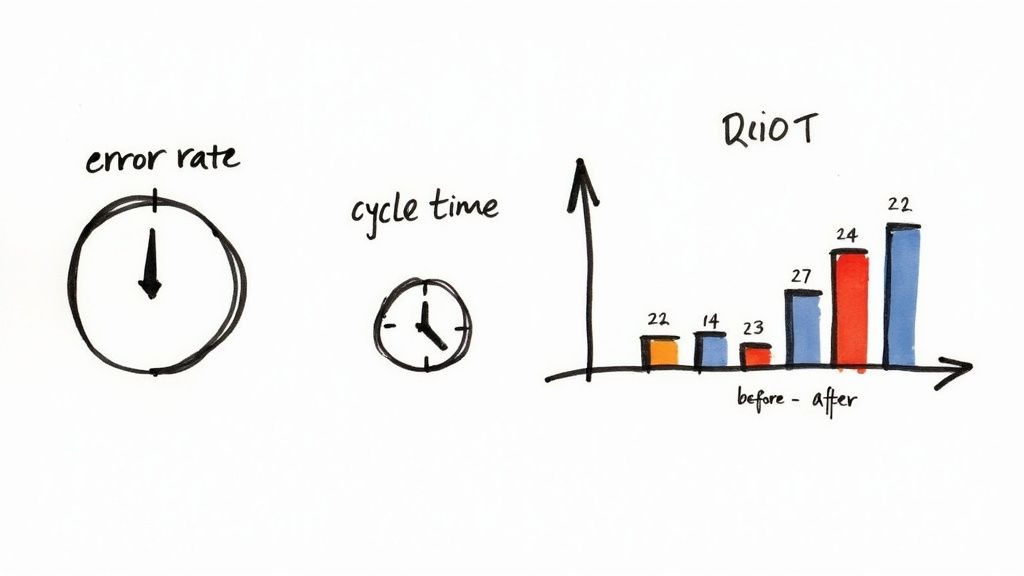

While ROI is non-negotiable, it doesn't paint the full picture. The true value of process automation solutions goes far beyond just saving money. To capture this, you need to track specific Key Performance Indicators (KPIs) that show how your operations have fundamentally improved.

These KPIs give you a clean before-and-after snapshot, proving that your processes aren't just cheaper—they're better, faster, and more reliable.

Tracking KPIs like cycle time and error rates provides undeniable proof that automation is improving the quality and speed of your operations. This data transforms the conversation from a cost-saving exercise into a strategic advantage.

Let’s dig into the most impactful KPIs you should be watching.

Critical Operational KPIs to Track

To get a complete view of automation’s impact, focus on these three core metrics. Each one shines a light on a different aspect of operational improvement, giving you a well-rounded story of your success.

- Process Cycle Time: How long does it take to get something done from start to finish? For example, how much time passes between receiving a vendor invoice and cutting the check? Automation can slash this from days to hours, or even minutes, giving your entire business a massive agility boost.

- Error Rate Reduction: Let's face it, manual work leads to human error. Typos, missed steps, and bad data entry are inevitable. Track the percentage of tasks that require rework before you automate. Once your solution is live, you’ll often see this number drop to nearly zero. That means higher quality work, better compliance, and happier customers.

- Employee Engagement and Satisfaction: This one might feel softer, but it’s just as critical. Survey your team before and after you roll out a new automation. Ask them how they feel about their daily grind and how much time they spend on high-value strategic work versus mind-numbing repetition. Freeing them from monotony almost always leads to a jump in morale and a drop in turnover.

This intense focus on operational excellence is why adoption is skyrocketing. In the United States alone, the market for process automation and instrumentation is projected to grow from USD 0.4 billion in 2025 to USD 0.6 billion by 2035. This growth underscores how companies are using automation to work smarter, not just harder. You can find more insights about this market growth on futuremarketinsights.com.

By combining hard ROI calculations with these vital KPIs, you can build a complete and compelling picture of how process automation solutions are delivering real, measurable value to your organization.

Process Automation Solutions in the Real World

Theory is great, but the real test for any business solution is how it performs out in the wild. This is where process automation stops being an abstract concept and becomes a tangible tool that solves persistent, everyday headaches across different departments.

Let's look at how these solutions are actually being used in key business functions, turning frustrating manual work into efficient, automated workflows.

Transforming Finance and Accounting

The finance department is often buried under a mountain of paperwork, from invoices to expense reports. This makes it a perfect candidate for automation, which can bring speed and precision to processes that have always been slow and painstaking.

A classic example is intelligent invoice processing. We've all seen accounts payable teams spend countless hours manually typing data from vendor invoices into accounting software. That work isn't just tedious; it's a breeding ground for human error, leading to incorrect payments and strained supplier relationships.

With process automation, an intelligent system can take over completely:

- Ingest Invoices: AI agents monitor a dedicated inbox, instantly grabbing new invoices the moment they arrive.

- Extract Data: Using Intelligent Document Processing (IDP), the system reads each invoice and accurately pulls key details like vendor name, invoice number, line items, and the total amount due.

- Validate Information: The extracted data is then cross-referenced with purchase orders in the ERP system to make sure everything lines up.

- Route for Approval: Once validated, the invoice is automatically sent to the right manager for approval, with polite nudges if a response is delayed.

This single automated workflow can shrink invoice processing time from days to mere minutes. It dramatically speeds up payment cycles and, more importantly, frees up the finance team to focus on strategic financial analysis instead of mind-numbing data entry. For a deeper dive into similar applications, you can explore these real-world business process automation examples.

Redefining Recruiting and HR

Talent acquisition is another area begging for an upgrade. Recruiters often spend the bulk of their day on administrative chores—sifting through hundreds of resumes, coordinating schedules, and sending follow-up emails—instead of actually engaging with top candidates.

AI-powered process automation acts as a recruiter's most valuable assistant. An AI agent can handle the entire top-of-funnel process, from the initial application all the way to a scheduled first interview.

By automating repetitive administrative tasks, recruiters can reclaim up to 60% of their time. This lets them shift from low-value screening to high-impact activities, like building relationships with promising candidates and acting as true talent advisors to hiring managers.

Imagine a workflow where an AI agent screens every single incoming resume against the job description. It shortlists the top 10% of candidates and then automatically reaches out to them to schedule an initial screening call. The agent can even sync with the candidate's calendar to find a time that works for everyone, all without a human lifting a finger. This ensures no great candidate ever slips through the cracks and dramatically shortens the time-to-hire.

Optimizing the Supply Chain

In logistics and supply chain management, accuracy and timing are everything. One small error in a purchase order or a delay in tracking a shipment can ripple through the entire system, messing up inventory levels and leaving customers unhappy.

Process automation brings much-needed reliability and visibility to these critical operations. Take the process of creating purchase orders (POs) and tracking shipments. An automated system can monitor inventory levels in real-time. When stock for an item dips below a set threshold, the system can:

- Automatically generate a purchase order with the correct item numbers, quantities, and supplier details.

- Route the PO for internal sign-off.

- Send the approved PO directly to the vendor's system.

- Once the vendor ships, the system tracks the delivery and gives the logistics team real-time updates.

This end-to-end automation doesn't just eliminate manual data entry mistakes; it ensures the supply chain runs like a well-oiled machine, preventing stockouts and making the entire operation more resilient.

Real-World Success Stories

To see the direct impact, let’s look at two mini-case studies reflecting the kind of results Red Brick Labs delivers.

Case Study 1: A Finance Team Reclaims Its Month-End

A mid-sized e-commerce company was drowning in a chaotic month-end closing process that took over eight business days. Their finance team was manually reconciling thousands of transactions from multiple payment gateways—a job that was both painfully slow and full of errors.

By implementing an automated reconciliation workflow, the company connected its sales platforms directly to its accounting software. An AI agent now pulls transaction data daily, matches it against bank statements, and flags any discrepancies for a human to review. The result? They slashed their month-end closing time by 50%, bringing it down to just four days and freeing up the team for higher-value financial planning.

Case Study 2: Achieving Near-Perfect Order Accuracy

A logistics provider was struggling with order fulfillment accuracy, which hovered around 97%. While that sounds high, the 3% error rate was leading to costly returns and frustrated customers. The root cause was simple: manual data entry from customer order forms into their warehouse management system.

They deployed an intelligent document processing solution to automate the entire order entry process. The system now reads incoming orders, extracts all the data with 99.9% accuracy, and populates it directly into the warehouse system. Within three months, their order accuracy hit 99.8%, drastically cutting operational costs and boosting customer loyalty.

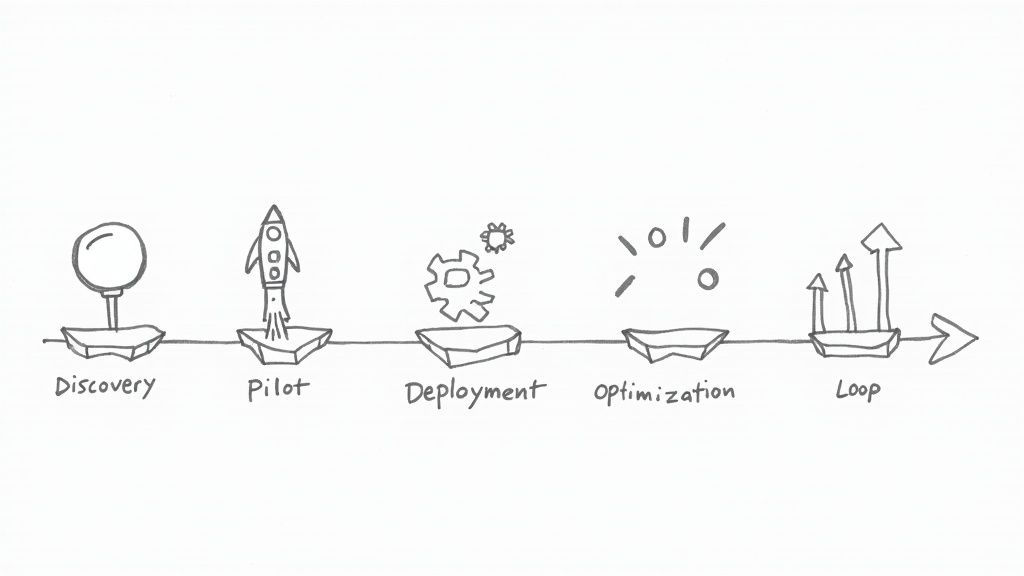

Your Step-By-Step Implementation Roadmap

So, where do you start? Bringing process automation into your business isn’t like flipping a switch. It’s a journey, and the best way to get there is by following a clear map. A phased approach is your best bet for getting real results, winning over your team, and dodging the usual headaches.

Think of it like building a house. You wouldn’t just show up with a hammer and start swinging. You'd start with a blueprint, pour a solid foundation, frame the structure, and only then add the finishing touches. Each step has to build on the last to make sure the final result is strong and reliable.

Stage 1: Discovery And Prioritization

First things first, you need to figure out where automation will give you the biggest bang for your buck. This is the discovery phase—hunting for those processes that are practically begging for an upgrade. You’re looking for the stuff that’s repetitive, high-volume, rules-based, and a magnet for human error.

Get leaders from different departments in a room and have them map out their day-to-day workflows. Ask them straight up: "What’s your biggest bottleneck? What task makes your team groan?"

The best candidates for automation usually share these traits:

- High Volume and Frequency: The task happens over and over, all day, every day.

- Clear, Standardized Rules: The steps are predictable, with very few curveballs.

- Prone to Human Error: Things like manual data entry are causing mistakes.

- Multiple Systems Involved: The work requires jumping between different software or screens.

Once you’ve got a list, rank them. Pit the potential impact against how hard it’ll be to implement. Your first target should be an easy win—something that delivers clear value without being a massive, complex project.

Stage 2: The Pilot Program

Before you go all-in with a company-wide rollout, you need to prove the concept. A pilot program is your small-scale, controlled test run. The goal is simple: confirm your idea works, show its value quickly, and iron out the kinks in a low-risk setting.

A successful pilot program is your most powerful tool for building momentum. It turns automation from a theoretical idea into a tangible success story that gets the rest of the organization excited and on board.

Pick one well-defined process from your priority list for the pilot. The perfect project should wrap up in 4–6 weeks and produce obvious metrics, like a 30% reduction in processing time. Nailing this pilot builds the business case you need to justify more investment. Our guide on how to automate business processes dives deeper into picking and structuring these crucial first projects.

Stage 3: Deployment And Scaling

With a successful pilot in the bag, it’s go-time. This stage is all about rolling out the automation solution to the entire team or department. The secret to success here is managing the change carefully.

Be crystal clear with the teams involved. Tell them what's changing, why it’s changing, and—most importantly—how it will make their jobs better. Good training is non-negotiable; everyone needs to be comfortable working alongside their new digital teammates.

Scaling is about taking what you learned from the pilot and applying it to other areas of the business. You can now confidently take on more complex workflows, building a whole portfolio of automations that deliver compounding value over time.

Stage 4: Optimization And Governance

Automation is never a "set it and forget it" deal. The final stage is a continuous loop of monitoring, tweaking, and governing your new automated world. You’ll need a solid governance framework to manage your growing army of bots and workflows, keeping everything secure and compliant.

Check in on the performance of your process automation solutions regularly. Are they hitting the KPIs you set? Could the workflow be even faster or smarter? Your business is always evolving, and your automations need to evolve with it to keep delivering maximum value for years to come.

Common Questions About Process Automation

Even with a clear plan, diving into process automation solutions can feel like a massive leap. It’s completely natural to have questions. I’ve seen countless business leaders wrestle with the same concerns: Where do we even start? What roadblocks should we expect? And how is this going to affect our people?

The best way to build confidence and set your project up for success is to tackle these questions head-on. Let's dig into some of the most common ones.

How Do We Identify The Best Processes To Automate First?

The temptation to automate everything at once is real, but the smartest move is to be picky. You're looking for the "low-hanging fruit"—those processes where automation delivers a quick, visible, and high-impact win. Nailing that first project builds serious momentum and makes a rock-solid case for future investment.

So, where do you find these golden opportunities? Look for tasks that check most of these boxes:

- High Volume: It’s something that happens over and over, maybe hundreds of times a day.

- Rules-Based: The process follows a clear, predictable "if this, then that" logic with very few exceptions.

- Prone to Human Error: It’s loaded with manual data entry or copying and pasting between systems—a perfect recipe for typos.

- Time-Consuming but Low-Value: The task chews up a ton of employee hours but doesn't require an ounce of critical thinking or creativity.

A simple way to prioritize is the Impact vs. Effort Matrix. Just plot your potential projects on a four-quadrant grid. That top-left square—High Impact, Low Effort—is your starting line. A perfect first project could be something like automatically generating weekly sales reports or processing standard employee expense claims.

What Are The Biggest Implementation Challenges?

Rolling out any new technology has its hurdles, and automation is no different. The key is anticipating these challenges so they don’t derail your project. And while technical glitches can happen, the biggest obstacles are almost always about people.

The two I see most often are:

- Resistance to Change: This is a big one. Employees might worry that automation is coming for their jobs or just feel uneasy about new ways of working. Open communication is your best friend here. Frame automation as a digital assistant that handles the grunt work, freeing them up for more interesting, strategic tasks. Better yet, get them involved in the discovery process to help pinpoint the very tasks they find most mind-numbing.

- Poor Data Quality: Automation is completely dependent on data. If your source data is a messy, inconsistent, or incomplete disaster, your automated processes will either fail or spit out garbage. Before you write a single line of code, do a data audit. Make sure your systems have clean, structured information. It’s the foundation for everything else.

Overcoming implementation roadblocks is less about the tech and more about the people and the process. Proactive change management and a real commitment to data hygiene will solve 90% of your problems before they even start.

Will Automation Replace Our Employees?

This is probably the most critical and emotionally loaded question of them all. The short answer? No.

The goal of automation isn't to replace people; it’s to augment them. It's about elevating their contribution to the business by shifting their focus from low-value, repetitive work to high-value, creative problem-solving.

Think about what happens when you automate invoice processing. Your accounts payable specialist stops being a data entry clerk. Suddenly, they have the time to become a financial analyst who manages vendor relationships, negotiates better payment terms, and investigates complex billing issues. Their role becomes more strategic and infinitely more valuable.

Automation handles the what so your team can focus on the why and the what’s next. It empowers them to apply their expertise, creativity, and critical thinking to challenges that software could never solve. By taking the robot out of the human, you unlock a whole new level of performance and job satisfaction across your organization.

Ready to get answers for your specific questions and find those high-impact automation opportunities? Red Brick Labs specializes in designing and building custom AI workflows that eliminate manual work and deliver measurable ROI. Schedule a discovery call with us today to see how we can help you scale.