Getting a handle on operational efficiency isn’t about just crunching numbers; it’s about creating a clear, repeatable system. I’ve always found it boils down to four core actions: Define the process you're looking at, select the right metrics for your goals, measure your baseline performance, and then optimize based on what the data tells you. This simple loop is what turns guesswork into genuine, data-driven improvements.

What Operational Efficiency Really Means Today

We throw the term "operational efficiency" around a lot, but what does it actually mean in practice?

At its heart, it’s about striking the right balance. You want to minimize the resources you pour into a process—things like time, money, and sheer effort—while maximizing what you get out of it, like better quality, faster delivery, and happier customers. It’s the art of getting more done with what you already have, but without sacrificing quality or burning out your team in the process.

For anyone leading operations, HR, or finance teams today, this idea has moved way beyond a simple cost-cutting exercise. It’s now one of the biggest drivers of business resilience and a real competitive advantage. Companies that get this right can pivot quickly when the market shifts, scale up without their headcount costs exploding, and create a much better experience for everyone involved, from customers to employees.

Shifting from a Task to a Strategy

In the past, measuring efficiency was often a background task—something to glance at in a quarterly report. Not anymore. Today, it’s a strategic must-do.

The real difference between market leaders and everyone else is the ability to turn raw operational data into smart business decisions. This guide is your practical roadmap for doing exactly that. We're going to skip the abstract theories and give you a concrete framework for measuring and improving the workflows that actually run your business.

Think of it as a playbook for making smarter, faster decisions backed by real data.

The goal isn't just to be busy; it's to be effective. True operational efficiency ensures that every action, every process, and every dollar spent directly contributes to strategic objectives and sustainable growth.

A structured approach helps you finally get answers to those nagging questions about your operations:

- Where are our hidden bottlenecks? You can finally pinpoint the friction that’s slowing down critical work.

- Are we putting resources in the right places? It ensures your team’s time and your budget are focused on high-impact activities.

- How do we grow without everything breaking? It’s about building systems that can handle more demand without collapsing.

To give you a clear map of where we’re headed, here’s a quick overview of the framework we’ll be following. It's a simple, logical flow designed to help you measure efficiency the right way.

A Simple Framework for Measuring Efficiency

| Phase | Core Objective | Key Activity |

|---|---|---|

| Define | Clearly identify the process or workflow to measure | Map the process and establish clear start and end points |

| Select | Choose metrics that align with business goals | Identify relevant KPIs like Cycle Time, Throughput, and Error Rate |

| Measure | Gather data to calculate performance baselines | Establish consistent data collection methods and conduct analysis |

| Optimize | Use insights to drive improvements and report on progress | Implement changes, apply automation, and visualize results |

By moving through these phases, you’re not just taking a one-time snapshot. You're building a system that creates a continuous loop of measurement and improvement.

Choosing the Right Metrics for Your Business

Alright, you’ve defined the scope of what you’re trying to fix. Now comes the critical part: picking the right metrics to guide you. It's tempting to track everything, but an endless list of KPIs is just noise. The real trick is to choose a handful of metrics that directly reflect your business goals and give you a balanced view of performance.

A classic mistake I see all the time is getting hyper-focused on just speed or cost. Sure, they’re important, but they don't tell the whole story. For a complete picture, you need to look at four key areas together: speed, quality, cost, and resource utilization. This keeps you from accidentally wrecking one area while trying to improve another—like pushing your team to work so fast that quality nosedives.

Let's dig into some of the most powerful metrics, broken down by the teams who use them most.

Key Metrics for Operations Teams

Operations is where the rubber meets the road. These teams live and breathe efficiency—their world is all about flow, output, and getting rid of friction. The following metrics are the bedrock for understanding how the core of your business is actually running.

-

Throughput: This is your raw output. It measures how many units a process spits out in a given timeframe. Think orders shipped per hour, customer tickets closed per day, or products assembled per shift. It’s your number one indicator of capacity.

- Formula:

Total Units Produced / Total Time - Real-World Scenario: An e-commerce warehouse has a goal to ship 500 orders a day. They measure their actual throughput and find they’re only hitting 420. That gap immediately tells them to look for a bottleneck, maybe in the packing or shipping stations.

- Formula:

-

Cycle Time: This metric follows a single unit of work from the very beginning of a process to the absolute end. It's a fantastic tool for sniffing out delays and really understanding what your customer experiences.

- Formula:

Process End Time - Process Start Time - Real-World Scenario: A software team starts tracking the cycle time for fixing bugs, from the moment a ticket is created to when the fix is deployed. They discover that tickets are stuck waiting for code review for a staggering 60% of the total cycle time. Boom—they’ve found their biggest bottleneck. For more specific examples, looking at industry standards like warehouse efficiency metrics can be incredibly helpful.

- Formula:

Essential Metrics for HR and People Ops

In HR, efficiency isn't just about pushing paperwork faster. It has a direct line to employee experience and your ability to bring in—and keep—great people. For People Ops, the most telling metrics often revolve around the time and money spent during the employee lifecycle.

- Time to Hire: This is a classic for a reason. It tracks the number of days between a job posting going live and a candidate signing on the dotted line. If this number gets too high, you're likely losing your best candidates to faster-moving competitors.

- Formula:

Offer Acceptance Date - Job Posting Date - Real-World Scenario: An HR team notices their average time-to-hire has ballooned to 60 days. They dig into the data and realize that manual resume screening is eating up over two weeks. That insight alone is enough to justify investing in a tool to automate that first pass.

- Formula:

Quality metrics are non-negotiable for HR and other service-focused departments. Pushing for speed without checks and balances leads to mistakes and costly rework. A balanced view ensures speed doesn't sabotage accuracy.

- First-Time Approval (FTA) Rate: This is a pure quality metric. It tracks the percentage of processes—like payroll runs or expense reports—that sail through on the first try without needing any corrections. A low FTA rate is a red flag for friction, errors, and wasted hours. The Global Payroll Efficiency Index 2025 found a worldwide FTA of just 72.61%, meaning nearly a third of all processes need to be redone.

Critical Metrics for Finance and Administration

For finance teams, efficiency is all about accuracy, compliance, and keeping costs in check. Their metrics are laser-focused on reducing the effort and expense of transactional work while maintaining airtight quality.

-

Cost Per Unit: This one is simple but powerful. It calculates the total cost to complete one unit of work, like processing a single invoice or onboarding a new vendor. It’s a direct measurement of how financially efficient a process is.

- Formula:

Total Process Cost / Total Number of Units - Real-World Scenario: A finance team finds their cost per invoice processed is $15, mostly because of all the manual data entry. They implement an automated workflow to extract the data, and that cost plummets to under $5 per invoice. Now the team has time for actual financial analysis instead of just keying in numbers.

- Formula:

-

Resource Utilization: This metric asks a simple question: are your resources—whether people, software, or equipment—actually being used effectively? For a finance team, it could mean tracking the percentage of time accountants spend on high-value analysis versus mind-numbing data entry. Our guide on optimizing resource allocation offers deeper strategies here. Keeping an eye on utilization ensures you’re getting the most bang for your buck.

Getting the Full Picture with Overall Equipment Effectiveness

While metrics like cycle time and throughput give you focused snapshots of your operation, Overall Equipment Effectiveness (OEE) delivers the panoramic view. It's the gold standard for a reason.

Originally born on the factory floor, OEE is now a powerhouse metric for almost any business process, from digital workflows to human-led services. It works so well because it boils down three critical aspects of performance into a single, brutally honest score.

At its heart, OEE asks three simple but profound questions about your process:

- Availability: Was the process even running when it was supposed to be?

- Performance: When it was running, was it moving as fast as it possibly could?

- Quality: Of the work it completed, how much of it was actually done right the first time?

Multiply the scores for those three components, and you get a holistic measure of your true productive time. It's not just about what you produced; it's about what you could have produced if everything ran perfectly.

Breaking Down the OEE Formula

To really get value out of OEE, you need to understand its parts. Let's ditch the manufacturing jargon and use a real-world example: an e-commerce fulfillment center scrambling to get online orders out the door.

-

Availability Score: This is all about uptime. It measures how much time your process was actually operational versus its planned production time. Every system crash, unexpected team huddle, or tool failure hits this number.

- Calculation:

(Actual Run Time / Planned Production Time) - Example: The fulfillment center is scheduled to run for 8 hours (480 minutes). But a server outage brings everything to a halt for 60 minutes. Their actual run time is only 420 minutes. The Availability score? 87.5% (420 / 480).

- Calculation:

-

Performance Score: This component gets at speed. It compares what you actually produced against what you should have produced during the time you were running. It's where slow work, minor hiccups, and inefficient tooling show their ugly faces.

- Calculation:

(Actual Output / Potential Output During Run Time) - Example: In their 420 minutes of run time, the team can ideally pack 5 orders per minute, giving them a potential of 2,100 orders. But thanks to slow label printers, they only managed 1,800. Their Performance score is just 85.7% (1800 / 2100).

- Calculation:

-

Quality Score: This one is straightforward—it’s your first-pass yield. It measures the percentage of work that was done perfectly, with no defects or rework needed. It catches everything from incorrect shipping labels to damaged products.

- Calculation:

(Good Units / Total Units Produced) - Example: Out of the 1,800 orders they packed, 90 had the wrong items or bad addresses and had to be redone. That means their Quality score is 95% (1710 / 1800).

- Calculation:

To get the final OEE score, you just multiply the three percentages: 0.875 (Availability) * 0.857 (Performance) * 0.95 (Quality) = 71.2%.

That single number tells the operations manager something crucial: 28.8% of their planned production time is vanishing into thin air due to a mix of downtime, slow performance, and errors.

Why OEE Matters Way Beyond the Factory Floor

The real power of OEE is its diagnostic capability. A low score doesn't just tell you you're inefficient; it points you directly to why. If Availability is in the gutter, you've got a reliability problem. If Performance is lagging, you need to fix your speed and flow. If Quality is tanking, your process controls aren't working.

By measuring Availability, Performance, and Quality in unison, OEE stops you from making a classic operational blunder: improving one metric at the expense of another. You can't just tell your team to work faster to boost your Performance score, because if they start making more mistakes, your Quality score will plummet, dragging down your overall OEE with it.

It’s one of the most reliable ways to get a handle on your true efficiency. In manufacturing and supply chain operations, world-class OEE is considered to be around 85%, but the average across most industries is a sluggish 60%.

Just look at Tesla's Gigafactories. Between 2020 and 2024, they leaned heavily into robotics, IoT, and AI for predictive maintenance, slashing production costs per vehicle by 30% and boosting efficiency by a staggering 40%. You can dig deeper into these kinds of stats in the OECD Compendium of Productivity Indicators 2025.

The good news? You don't need a Gigafactory budget. Today, AI-powered monitoring can automate OEE tracking, moving you from clunky spreadsheets to real-time dashboards that can spot bottlenecks before they ever hurt your bottom line.

Building Your Measurement System from the Ground Up

Knowing what to measure is the easy part. Actually building the system to do it consistently is where the real work begins. Creating a reliable measurement framework isn't about buying the fanciest software—it's about methodically connecting your processes to the data they produce so you can finally trust the numbers you see.

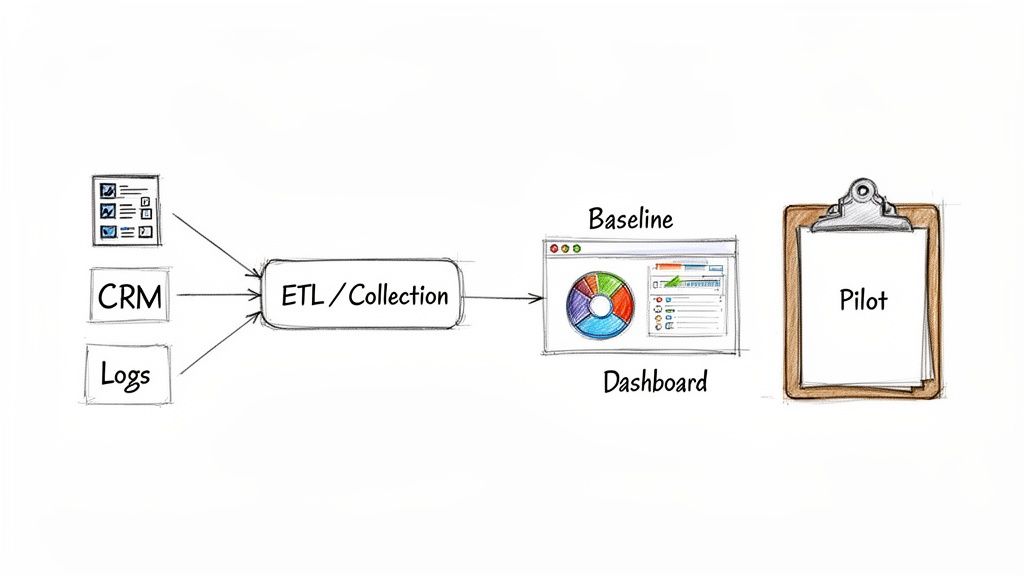

Your first job is to figure out where your data actually lives. It’s almost always scattered across more places than you'd think. Your key data sources will likely include:

- Enterprise Resource Planning (ERP) systems: These are goldmines for production numbers, inventory levels, and financial transaction data.

- Customer Relationship Management (CRM) software: Your CRM holds critical info on sales cycle times, customer interactions, and support ticket resolutions.

- Human Resources Information Systems (HRIS): This is where you’ll find the raw data for metrics like time-to-hire and employee turnover.

- Simple logs and spreadsheets: Never overlook the basics. Plenty of teams still track crucial steps in shared files, which can be a fantastic starting point.

Once you’ve located the information, you need a plan to collect it. This can be as simple as manual entry or as complex as automated API pulls, which are perfect for getting real-time data from modern software. The key isn't perfection; it's consistency. Whatever method you choose, stick with it so your data is comparable over time.

Establishing Your Baseline and Data Integrity

Before you can claim any improvements, you have to know where you're starting from. This is your baseline—a brutally honest snapshot of your current performance. This initial measurement becomes your single source of truth, the benchmark against which every future effort will be judged.

But a baseline is only as good as the data it’s built on. You have to prioritize data integrity. This just means making sure the information you're collecting is accurate, complete, and consistently formatted. If one team logs cycle time in hours and another uses days, your entire analysis is worthless. Establishing clear data entry rules from day one is non-negotiable.

Your measurement system is like the foundation of a house. If it’s built on messy, inconsistent data, everything you try to build on top of it will eventually crumble. Take the time to clean your data and standardize your collection methods upfront.

For a deeper dive into systematically analyzing your operations, it's worth understanding the core concepts of process mining. Learning about what is process mining can give you a powerful framework for turning raw event logs from your systems into a visual map of your actual workflows, exposing bottlenecks you never knew existed.

Launching a Pilot Measurement Project

Theory is great, but the best way to figure this out is to just do it. Running a small, focused pilot project is the perfect way to test your system, work out the kinks, and demonstrate value quickly.

Let's walk through a common scenario: an HR team wants to automate its candidate screening process to slash its Time to Hire metric.

Scenario: The HR Candidate Screening Pilot

The team’s goal is to see if an AI tool can screen resumes faster and more accurately than a human, freeing up recruiters for high-value work like interviews and outreach.

- Define the Scope: The pilot will only focus on the initial screening stage for a single high-volume role, like "Customer Support Representative." The clock starts when an application is received and stops when the candidate is either rejected or passed to a hiring manager.

- Establish the Baseline: For two weeks, the team manually tracks their existing process. They log the exact time spent on each resume and count how many "qualified" candidates they find versus how many are later rejected by the hiring manager.

- Calculate Baseline Metrics:

- Average Cycle Time per Application: They discover it takes an average of 8 minutes to manually review a single resume.

- Throughput: One recruiter can screen roughly 60 applications per day.

- Quality Rate: Hiring managers report that a frustrating 25% of the candidates passed to them don't actually meet the basic job requirements.

- Set Improvement Targets: With a clear baseline, they set realistic goals for the automation. They aim to reduce cycle time to under 1 minute per application and improve the quality rate so that fewer than 10% of candidates are rejected by managers at the next stage.

By running this pilot, the team isn't just testing a tool. They're proving the value of measurement itself and building a bulletproof business case for a wider rollout—backed by hard numbers. This focused approach gives you the data-driven story you need to get buy-in for bigger efficiency projects down the road.

Driving Real Improvement with AI and Automation

Once you have clear, reliable numbers in front of you, the real work—and the real fun—begins. This is the moment you shift from being a spectator of your own operations to an active driver of change. AI-powered automation is the engine that turns insights from your KPIs into tangible, bottom-line improvements.

Think about it. Instead of just knowing your Cost Per Unit is too high, you can deploy AI to actively fix it. This isn't about some fuzzy, far-off potential; it's about taking targeted action. When you know which metrics are lagging, you can point specific automation solutions directly at the problem, creating a powerful cycle of continuous optimization.

The beauty of this approach is its precision. You’re no longer making broad, hopeful changes and crossing your fingers. You're performing surgical strikes on your biggest bottlenecks with tools designed for the job.

From Insight to Action Across Departments

Automation directly impacts the core metrics we've discussed, but its application looks a little different depending on the department. The key is to connect the right type of AI to the specific KPI you want to improve. This creates a clear cause-and-effect relationship, making it incredibly easy to calculate your return on investment.

Here are a few practical examples of how this plays out in the real world:

-

Finance Teams Tackling High Costs: A finance department is getting buried under a high Cost Per Invoice and a painful Error Rate. They can implement a document intelligence workflow. This AI can rip through thousands of invoices in minutes, extracting data and all but eliminating manual entry—the very thing driving up costs and causing mistakes. The result is a direct, measurable drop in two of their most critical KPIs.

-

HR Teams Slashing Cycle Times: An HR team is dealing with a painfully long Time to Hire. They can bring in recruitment automation. An AI agent can screen thousands of resumes against job criteria overnight, flagging top candidates and even scheduling the first round of interviews. This directly attacks the biggest bottleneck in their hiring pipeline, cutting the Cycle Time from weeks down to just a few days.

-

Research Teams Boosting Throughput: A competitive intelligence team is limited by how many reports they can manually review. By deploying an intelligent research agent, they can monitor hundreds of sources at once, summarizing key findings and boosting their Throughput of actionable insights by an order of magnitude.

The Financial Case for Intelligent Automation

Connecting AI implementation to a measurable ROI is straightforward once you’ve done the hard work of baselining your KPIs. The productivity gains aren't just a vague promise; they become a clear, forward-looking measure of efficiency, quantified by cost reductions and output boosts you can see right after implementation.

In fact, recent industry data shows AI adopters are slashing logistics costs by 15%, trimming inventory by 35%, and surging service efficiency by a whopping 65%. With supply chain disruptions hitting revenues hard, it's no wonder that 93% of executives rank efficiency as a top priority. And 62% see AI as "very effective" in getting them there.

Automation isn't just about doing the same things faster. It's about fundamentally redesigning workflows to eliminate the root causes of error, delay, and waste. The result is a far more resilient and scalable operation.

This creates a powerful, self-reinforcing loop. The data generated by your newly automated processes becomes the input for the next round of analysis. The AI doesn’t just perform the task; it also provides perfect, structured data about its own performance. Cycle times, error rates, and throughput are all tracked automatically. This information feeds right back into your dashboards, revealing new opportunities for optimization.

To see how you can apply these technologies to future-proof your workflows, it’s worth exploring how to implement smart warehouse automation design for even greater gains.

This continuous feedback loop is what drives lasting change. For leaders looking to get more from their operations, our guide on operational efficiency improvement strategies offers more frameworks to consider. By pairing measurement with automation, you build an operational engine that not only runs smoothly but actually gets smarter and more efficient over time.

Common Questions About Measuring Operational Efficiency

Diving into a new measurement framework always kicks up a few practical questions. As you start trying to quantify your operational efficiency, you're going to hit situations that feel unique to your business. Let's walk through some of the most common questions I hear from leaders when they start this journey.

Where Do We Start if We Have No Existing Measurements?

Starting from scratch feels daunting, but it’s actually a golden opportunity to build your system the right way from the ground up. The secret is to avoid trying to boil the ocean. Don't attempt to measure every single process across the company all at once.

Instead, pick one high-impact, high-pain process and start there. Find a workflow that everyone knows is slow, expensive, or a magnet for errors. Things like customer onboarding, vendor payments, or invoice approvals are often perfect candidates.

Then, pull the team together to map out that single process and choose just two or three simple metrics to track. You don't need anything fancy—total cycle time and error rate are incredibly powerful starting points. You can even track this data in a spreadsheet for a few weeks to get a baseline. This focused effort gives you the hard data you need to justify investing in better tools and automation down the road.

How Can We Measure Efficiency for Creative or Non-Repetitive Work?

This is a great question. Measuring knowledge work is definitely different than clocking an assembly line, but it's absolutely possible. You just have to shift your focus from the volume of output to its value and impact.

Instead of trying to track "units per hour," you look for friction points in the creative or strategic process.

- Project Milestone Completion Rate: Are projects hitting their key deadlines, or are they constantly getting bogged down?

- Ratio of Planned vs. Unplanned Work: How much of the team's time is spent on strategic goals versus putting out unexpected fires?

- Time on Value-Adding Tasks: How much of a designer’s day is actually spent designing versus hunting for information or sitting in meetings that could have been an email?

Qualitative feedback is huge here, too. For instance, a creative team could track how many internal requests they nail on the first pass without needing major revisions. The goal isn’t to put a stopwatch on creativity; it's about finding and clearing the operational roadblocks that get in the way of great work.

What Is the Biggest Mistake Companies Make When Measuring Efficiency?

The single most common trap I see is focusing only on speed or cost-cutting while completely ignoring quality. It's a recipe for disaster. When you push a customer support team to just reduce call times, you get rushed answers, unresolved problems, and furious customers.

A balanced scorecard is non-negotiable. Efficiency gains that come at the expense of quality aren't real gains—they are deferred problems that will pop up somewhere else, usually with a much higher price tag.

Always pair a "speed" metric with a "quality" metric. If you start measuring "invoices processed per hour," you absolutely must also track the "invoice accuracy rate." This simple check and balance ensures your gains are both real and sustainable.

How Often Should We Review Our Operational Efficiency Metrics?

The right cadence depends entirely on the natural rhythm of the process you’re measuring. There’s no single answer here.

For high-volume, fast-moving workflows like e-commerce fulfillment or IT support tickets, you should be looking at the data in real-time or daily. For longer-cycle processes, like a B2B sales pipeline or a software development sprint, a bi-weekly or monthly review makes more sense. Broader, strategic metrics can be reviewed quarterly alongside other key business results.

The key is to find a rhythm that helps you spot negative trends early enough to do something about them, without micromanaging the normal, everyday ups and downs of the business.

At Red Brick Labs, we design and build the custom AI workflows that turn your efficiency metrics into measurable ROI. We architect intelligent automation that eliminates manual work, reduces costs by 30-60%, and helps you scale without limits. See how we can transform your operations by visiting us at https://redbricklabs.io.