In a competitive landscape where operational efficiency is paramount, understanding your workflows is no longer optional-it's the foundation of growth. Ambiguous processes lead to wasted resources, frustrated teams, and missed opportunities. This is where business process mapping techniques come in. They are the essential tools that transform tangled, invisible workflows into clear, actionable diagrams, providing the blueprint for sustainable scaling and strategic optimization.

By visualizing how work actually gets done, you can pinpoint bottlenecks, eliminate redundancies, and-most importantly-identify prime candidates for intelligent automation. A well-executed map serves as a single source of truth, aligning stakeholders from operations and finance to HR and IT. This clarity is the first step in any successful digital transformation, ensuring that technology investments target the most impactful areas of the business.

This guide moves beyond theory, offering a practical roundup of 10 distinct business process mapping techniques. For each method, we'll break down not just what it is, but how to use it step-by-step, its specific pros and cons, and crucial indicators that signal a process is ripe for automation. Understanding how to effectively manage process improvement initiatives is crucial for translating your mapped processes into tangible results, and this article provides the foundational knowledge to begin that journey.

We will explore a range of powerful visualization tools, from the universally recognized Flowchart to the highly specialized Value Stream Map and the rigorous BPMN standard. You'll gain actionable insights to select the right technique for your specific challenge, whether you're streamlining a high-volume document workflow or optimizing an entire supply chain. Let’s start turning your operational complexities into a strategic advantage.

1. Flowchart Mapping

Flowchart mapping is the quintessential and most widely recognized of all business process mapping techniques. It provides a simple yet powerful visual representation of a process from start to finish. Using a standardized set of symbols, it illustrates the sequence of steps, decision points, and the overall flow of work, making it an excellent starting point for any process analysis initiative.

This technique, popularized by pioneers like Frank Gilbreth and W. Edwards Deming, uses basic shapes connected by arrows to create a clear, linear path. A rectangle typically represents a task or activity, a diamond signifies a decision point (usually with "yes" or "no" branches), and an oval indicates the start or end of the process. This simplicity is its greatest strength, offering an intuitive way to document and understand workflows.

Key Characteristics & Benefits

- Simplicity and Clarity: Flowcharts are easy for anyone, regardless of technical background, to create and understand. This universal accessibility makes them ideal for training, onboarding, and cross-departmental communication.

- Problem Identification: By visualizing each step, teams can quickly spot redundancies, bottlenecks, or logical gaps in a process. For example, a customer onboarding flowchart at a major bank might reveal multiple, unnecessary data entry points.

- Standardization Foundation: It serves as a foundational tool for standardizing procedures, ensuring everyone follows the same steps for consistent outcomes, a practice perfected in manufacturing by companies like Toyota.

Expert Insight: The true power of a flowchart isn't just in the final diagram, but in the collaborative process of creating it. It forces stakeholders to discuss and agree upon each step, uncovering hidden assumptions and misalignments along the way.

Automation Readiness Indicators

A process documented with a flowchart is a strong candidate for automation if it exhibits:

- High Frequency of Decision Diamonds: Multiple, rule-based decision points (e.g., "Is the invoice amount over $500?") are perfect for automation software to handle.

- Sequential, Repetitive Steps: A long chain of rectangular process boxes with few deviations indicates a routine, manual task ripe for optimization.

- Clear Start and End Points: Well-defined triggers and outcomes make it easier to integrate an automated solution. A software development workflow at a company like Microsoft might use a flowchart to map a code deployment process, where the "commit code" step (start) and "deploy to production" (end) are clear automation boundaries.

2. Swimlane Diagram (Cross-Functional Flowchart)

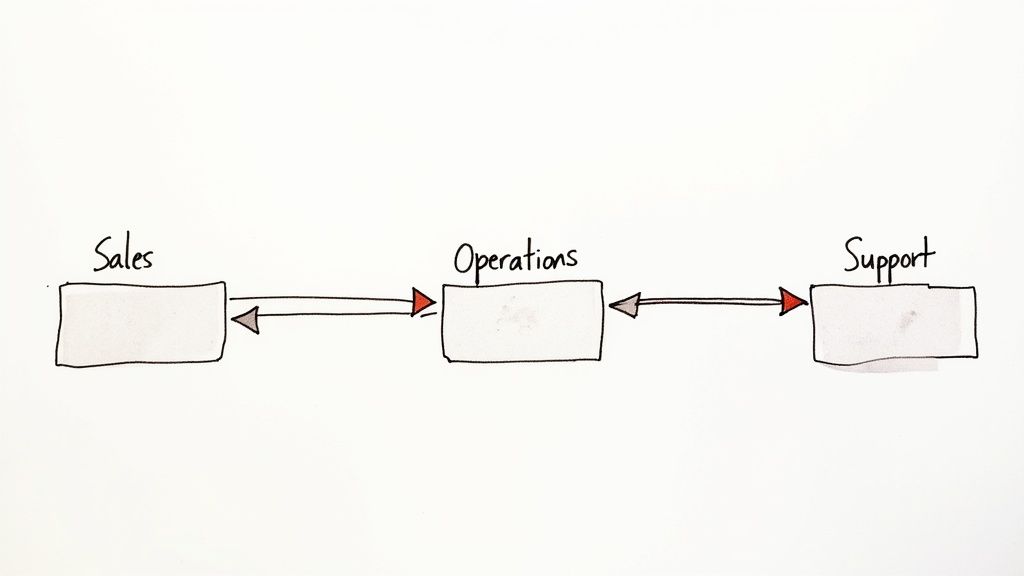

The Swimlane Diagram, also known as a cross-functional flowchart, is one of the most effective business process mapping techniques for visualizing how work moves between different people, teams, or departments. It enhances the standard flowchart by organizing process steps into horizontal or vertical "lanes," with each lane representing a distinct actor or functional area. This structure provides immediate clarity on who is responsible for each task.

Pioneered by consultants like Geary Rummler and Alan Brache to improve organizational performance, this method excels at highlighting handoffs between teams. Each time a process arrow crosses a line from one lane to another, it represents a transfer of responsibility. This visual cue is invaluable for identifying communication gaps, delays, and potential points of failure in complex, multi-stakeholder workflows.

Key Characteristics & Benefits

- Clarity of Responsibility: Swimlanes eliminate ambiguity by clearly assigning ownership for every step of the process. This helps prevent tasks from being dropped and fosters accountability.

- Handoff Visualization: The diagram makes it easy to see the number and complexity of handoffs. An insurance claim processing workflow, for example, can instantly show the back-and-forth between the claims adjuster, fraud department, and payment processing teams.

- Cross-Functional Improvement: By bringing representatives from each "lane" together to map the process, organizations can identify inter-departmental bottlenecks and collaboratively streamline the entire workflow, not just one siloed part.

Expert Insight: The most revealing part of a swimlane diagram is often the "white space" - the time a task waits between handoffs. Mapping these delays explicitly can uncover massive opportunities for process acceleration that are otherwise invisible.

Automation Readiness Indicators

A process mapped with a swimlane diagram is a prime candidate for automation when it displays:

- Frequent Lane Crossings: A high volume of handoffs between departments (e.g., Sales to Legal to Finance) for approvals or data entry often signifies manual, time-consuming coordination that can be automated.

- Repetitive Tasks Within a Single Lane: If one lane, such as "Accounts Payable," contains a sequence of routine steps like "Receive Invoice," "Enter Data," and "Match PO," that specific function is ready for automation.

- Role-Based Decision Points: Processes with rules based on roles (e.g., "If request from VP, approve automatically") are easily translated into an automation workflow. A loan approval process in a financial institution is a classic example where handoffs between loan officers, underwriters, and compliance are automated based on predefined rules.

3. Value Stream Mapping (VSM)

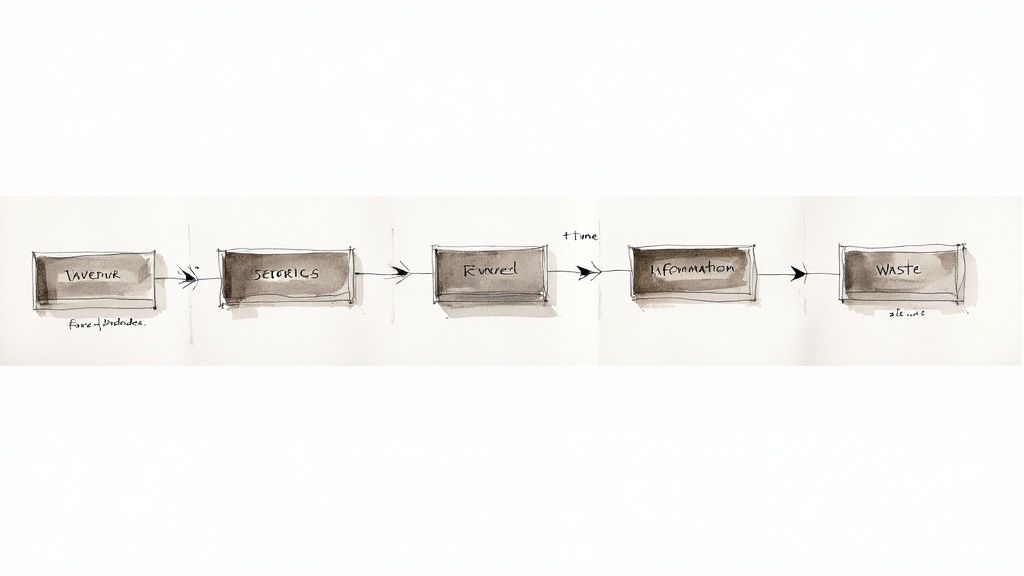

Value Stream Mapping (VSM) is a cornerstone of lean methodology and one of the most powerful business process mapping techniques for identifying and eliminating waste. Unlike a simple flowchart, VSM visualizes the entire flow of materials and information required to bring a product or service from its origin to the customer. It meticulously tracks metrics like cycle time, lead time, and inventory levels to distinguish between value-adding and non-value-adding activities.

This technique, refined within the Toyota Production System, goes beyond just mapping steps; it quantifies the process. By creating a "current state" map, organizations can see exactly where delays, excess inventory, and unnecessary movements occur. The ultimate goal is to design a "future state" map that represents a leaner, more efficient process, a strategy famously used by companies like Harley-Davidson to overhaul their manufacturing lines.

Key Characteristics & Benefits

- Waste Identification: VSM is specifically designed to expose the eight wastes of lean (e.g., waiting, overproduction, defects). This focus makes it highly effective for targeted process improvement initiatives.

- Holistic System View: It connects material flow with information flow, providing a comprehensive picture of the entire value stream, not just isolated tasks. This is crucial for improving workflow efficiency across departments.

- Data-Driven Decisions: The map is rich with performance metrics, allowing teams to base improvement decisions on quantitative data rather than assumptions. Virginia Mason Medical Center successfully applied this to reduce patient wait times and improve care delivery.

Expert Insight: A VSM is not a "one and done" exercise. The most successful organizations treat their value stream maps as living documents, continuously updating them as they implement improvements and as market demands change. The future state map of today becomes the current state map of tomorrow.

Automation Readiness Indicators

A process documented with a VSM is a strong candidate for automation if it shows:

- High Wait Times Between Steps: Significant delays in the timeline at the bottom of the map indicate information or material handoffs that can be accelerated with automated triggers and data transfers.

- Information Flow Loops: If the information flow arrows show data moving back and forth between manual systems (e.g., re-keying information from email to a CRM), it signals a prime opportunity for system integration.

- High Inventory or Backlog: Piles of work-in-progress (represented by the triangle symbol) often point to manual bottlenecks that automation can clear, such as document processing or approval queues.

4. Business Process Model and Notation (BPMN)

Business Process Model and Notation (BPMN) is a highly standardized graphical language among business process mapping techniques, designed to bridge the communication gap between business and IT. Maintained by the Object Management Group (OMG), it provides a rich, formal notation that allows for the creation of precise, executable process models that can be understood by all stakeholders, from business analysts to software developers.

Unlike a simple flowchart, BPMN uses a comprehensive and specific set of symbols to represent complex process logic. It details events (circles), activities (rounded rectangles), and gateways (diamonds) that control the flow of the process. This level of detail makes BPMN the gold standard for projects where precision, compliance, and direct translation into automated workflows are critical, such as in large-scale enterprise resource planning (ERP) implementations at companies like SAP.

Key Characteristics & Benefits

- Precision and Standardization: BPMN's formal notation eliminates ambiguity, ensuring that processes are interpreted consistently across the organization. This is crucial for regulated industries like banking and healthcare for documenting operations.

- Business-IT Alignment: It serves as a common language, enabling business stakeholders to model processes in a way that technical teams can directly use for implementation and automation.

- Executable Models: BPMN diagrams are not just visual aids; they can be directly imported into Business Process Management (BPM) software like Camunda or Bizagi to create executable process applications.

Expert Insight: The real advantage of BPMN is its ability to model exceptions and complex event-driven logic. While a flowchart shows the "happy path," BPMN excels at mapping out all the potential deviations, error handling, and parallel flows that occur in real-world business operations.

Automation Readiness Indicators

A process documented with BPMN is inherently designed for automation. Key indicators include:

- Use of Message and Timer Events: The presence of event symbols (like an envelope for a message or a clock for a timer) explicitly defines triggers for automated actions.

- Complex Gateways: Exclusive, parallel, or inclusive gateways (diamonds with internal markers) define sophisticated, rule-based logic that is ideal for workflow engines to execute.

- Service Tasks and Script Tasks: BPMN includes specific task types meant to call an automated service or execute a script, making the intention to automate business processes clear within the model itself. A government agency standardizing its permit approval workflow would use these to define automated system checks and notifications.

5. Data Flow Diagram (DFD)

A Data Flow Diagram (DFD) is one of the more technical business process mapping techniques, focusing specifically on how information moves through a system or process. Instead of mapping tasks, a DFD illustrates the journey of data: where it comes from, how it gets processed, where it is stored, and where it goes. It provides a high-level, graphical view of a system's data-handling requirements.

Pioneered by structured analysis proponents like Tom DeMarco and Ed Yourdon, this technique uses four core symbols: circles for processes that transform data, arrows for data flows, open-ended rectangles for data stores (like databases), and squares for external entities that produce or consume data. This focus makes DFDs invaluable for systems analysis and software development, especially when designing new information systems or auditing existing ones.

Key Characteristics & Benefits

- System Scope Definition: DFDs excel at defining system boundaries by clearly showing interactions with external entities. A CRM system DFD, for instance, would show how customer data enters from a web form and flows to a sales database.

- Data-Centric Analysis: It shifts the focus from procedural steps to the information itself, helping teams understand and improve data integrity, storage, and access. This is critical for designing robust e-commerce platforms or secure banking systems.

- Layered Detail (Decomposition): DFDs can be created in layers, from a high-level "Context Diagram" (Level 0) down to more detailed lower-level diagrams. This allows stakeholders to engage at their preferred level of complexity.

Expert Insight: A common mistake is to confuse a DFD with a flowchart. A flowchart shows the sequence of control or the order of operations, while a DFD shows the movement of data. They answer different questions: "What happens next?" versus "Where does the information go?"

Automation Readiness Indicators

A system documented with a DFD is a prime candidate for automation when it reveals:

- High-Volume Data Flows: Arrows representing frequent, large-scale data transfers between processes or systems (e.g., "customer order details") suggest a need for automated data pipelines.

- Multiple Manual Transformations: A series of process circles representing manual data entry, validation, or formatting is a clear signal for automation.

- Data Bottlenecks at Stores: If data flows consistently get stuck waiting for manual updates or retrievals from a data store, it indicates a need for an automated integration or data synchronization tool. A healthcare information system DFD might show a delay in patient data moving from the registration process to the electronic health record store, highlighting a key automation opportunity.

6. Fishbone Diagram (Ishikawa Diagram)

While many business process mapping techniques focus on the sequence of steps, the Fishbone Diagram, or Ishikawa Diagram, is a powerful tool for root cause analysis. It visually organizes and explores the potential causes of a specific problem or effect, helping teams look beyond symptoms to find the underlying issues impacting a process. Its unique structure resembles a fish skeleton, with the "head" representing the problem and the "bones" branching out into categories of potential causes.

Developed by quality control pioneer Kaoru Ishikawa, this technique is a cornerstone of problem-solving methodologies like Six Sigma and Lean. The main "bones" typically represent the 6Ms of manufacturing: Manpower, Method, Machine, Material, Measurement, and Milieu (Environment). These categories provide a structured framework for brainstorming sessions, ensuring a comprehensive exploration of all factors that could contribute to a process failure, such as a high defect rate in an automotive plant or a recurring bug in a software development cycle.

Key Characteristics & Benefits

- Structured Brainstorming: The diagram provides a clear, categorized structure that prevents brainstorming sessions from becoming disorganized. It prompts teams to consider a wide range of potential causes systematically.

- Root Cause Focus: It forces a shift from blaming individuals to analyzing the system and process. By digging into sub-causes (the smaller bones), teams can uncover the fundamental reasons for a problem, like an out-of-date procedure (Method) causing data entry errors (Problem).

- Cross-Functional Collaboration: The visual and comprehensive nature of the Fishbone Diagram makes it an excellent tool for involving diverse teams. It helps build a shared understanding of a complex problem, combining perspectives from operations, engineering, and customer service.

Expert Insight: The Ishikawa Diagram is most effective when used as a live, collaborative tool. Its value comes from the discussion it generates, forcing a team to ask "Why?" multiple times to drill down from a high-level cause to a specific, actionable root cause.

Automation Readiness Indicators

A process problem analyzed with a Fishbone Diagram points toward automation opportunities when the causes are:

- Concentrated in "Manpower" and "Method": If many root causes are related to human error, inconsistent training, or complex manual procedures, it signals a high potential for automation to standardize the workflow and reduce variability.

- Linked to "Measurement" and Data Handling: Causes stemming from manual data collection, transcription errors, or slow measurement processes are clear indicators for automated data capture and analysis tools.

- Repetitive and Rule-Based: If a cause analysis in a healthcare setting reveals that adverse events are linked to staff repeatedly failing to follow a complex, rule-based checklist, that checklist process is an ideal candidate for an automated workflow.

7. Process Activity Mapping

Process Activity Mapping is one of the more analytical business process mapping techniques, moving beyond simply documenting steps to critically evaluating their worth. It categorizes each activity into one of three distinct types: value-added, business-necessary, or non-value-added. This framework provides a powerful lens for identifying and eliminating waste directly from a workflow.

Popularized by Lean and Kaizen continuous improvement advocates, this method forces teams to scrutinize the purpose behind every action. A "value-added" activity is something the customer is willing to pay for. "Business-necessary" activities don't add customer value but are required for regulatory, legal, or operational reasons. "Non-value-added" activities are pure waste and should be eliminated. This granular analysis is crucial for true process optimization.

Key Characteristics & Benefits

- Waste Elimination: Its primary benefit is the systematic identification of non-value-added steps like unnecessary handoffs, delays, or rework. A supply chain analysis using this technique might reveal redundant quality checks that can be consolidated.

- Customer-Centric Focus: By defining value from the customer's perspective, it aligns process improvement efforts with what truly matters, enhancing satisfaction and loyalty.

- Resource Optimization: It ensures that time, money, and personnel are focused on activities that either generate customer value or are essential for business operations, improving overall efficiency.

Expert Insight: The most challenging yet rewarding part of Process Activity Mapping is collectively defining what "value" means. This conversation often unearths deep-seated assumptions about why things are done a certain way, paving the path for transformative change rather than just incremental tweaks.

Automation Readiness Indicators

A process documented with activity mapping is a strong candidate for automation if it shows:

- High Volume of Business-Necessary Tasks: Activities like data validation, compliance checks, or report generation are essential but don't add direct customer value. Automating these frees up human talent for value-added work.

- Identified Non-Value-Added Steps: If a non-value-added step like data re-entry cannot be eliminated, it is a prime target for automation to minimize its resource drain.

- Clear Categorization: When activities can be easily and consistently sorted into the three categories, it signifies a rule-based process. This structure is ideal for an RPA bot or workflow automation platform to execute, such as in an HR onboarding process where form-filling is automated.

8. Service Blueprint

A Service Blueprint is a highly specialized business process mapping technique that visualizes a service experience from the customer's perspective. It goes beyond a standard process map by layering the customer's journey with the corresponding employee actions and support systems, both visible and invisible to the customer. This holistic view connects what the customer experiences directly to the internal processes required to deliver that experience.

Developed by service marketing pioneer G. Lynn Shostack, this technique is essential for industries where customer interaction is paramount. It meticulously charts the customer's steps, the physical evidence they encounter, the actions of front-stage (customer-facing) employees, the activities of back-stage (non-customer-facing) employees, and the underlying support processes. This comprehensive diagram reveals the intricate web of dependencies that shape the service quality.

Key Characteristics & Benefits

- Customer-Centric View: Unlike internally focused maps, it anchors every process to a specific customer action or touchpoint, ensuring that operational improvements directly enhance the customer experience.

- Identifies Fail Points: By linking front-stage and back-stage actions, it clearly shows where a breakdown in an internal process can lead to a poor customer outcome. A hotel blueprint might reveal that a slow laundry service (back-stage) directly causes delays in room availability (customer experience fail point).

- Cross-Functional Alignment: It provides a shared understanding of the service delivery ecosystem, helping different departments (like sales, support, and operations) see how their roles interconnect to serve the customer.

Expert Insight: The most valuable part of a service blueprint is its ability to highlight the "line of visibility." Understanding precisely what the customer sees versus what happens behind the scenes is critical for managing perceptions and designing moments that delight.

Automation Readiness Indicators

A service documented with a blueprint is a strong candidate for automation where it shows:

- High-Volume Back-Stage Tasks: Repetitive, non-customer-facing activities like data entry, system updates, or report generation are ideal for automation to free up staff for more valuable, customer-facing work.

- Critical Support Processes: A slow or error-prone manual support process (e.g., credit check, inventory verification) that frequently causes delays for front-stage employees and customers can be automated for speed and reliability.

- Standardized Customer Communications: Trigger-based notifications, appointment reminders, or status updates mapped in the customer journey can be easily automated, as seen in airline and logistics companies like FedEx to enhance customer communication.

9. Deployment Flowchart

A Deployment Flowchart, also known as a cross-functional flowchart, is a specialized variant of business process mapping techniques that visualizes not just the steps of a process but also who is responsible for them. It organizes activities into parallel "swimlanes" representing different departments, roles, or even physical locations, making it exceptionally clear how work is handed off between teams.

Pioneered within Six Sigma methodologies at companies like Motorola and General Electric, this technique extends the basic flowchart by adding a layer of accountability. Each step is placed within the lane of the responsible party, immediately highlighting inter-departmental dependencies, communication gaps, and potential delays during handoffs. This focus on ownership makes it invaluable for improving collaborative, multi-stage workflows.

Key Characteristics & Benefits

- Clarifies Roles & Responsibilities: Its primary benefit is eliminating ambiguity. By mapping tasks to specific functional lanes (e.g., Sales, Finance, Operations), it becomes instantly clear who does what, preventing tasks from being dropped or duplicated.

- Highlights Handoff Inefficiencies: The visual movement of the process flow from one lane to another pinpoints every handoff. This allows teams to analyze these critical points for delays, miscommunication, or bottlenecks, such as a multi-location service process at a retail chain.

- Improves Cross-Functional Collaboration: By visualizing the end-to-end process across departments, it fosters a shared understanding and encourages teams to see how their work impacts others, breaking down organizational silos.

Expert Insight: The most revealing moments when creating a Deployment Flowchart occur when arrows cross between lanes. These handoffs are the process's weakest points and the biggest opportunities for improvement and automation.

Automation Readiness Indicators

A process documented with a Deployment Flowchart is a strong candidate for automation if it exhibits:

- High Volume of Lane Crossings: Frequent handoffs between departments, especially for simple approvals or data transfers, signal a need for an automated workflow or integration.

- Repetitive Tasks Within a Single Lane: If a specific role's swimlane contains a sequence of routine, manual steps, these are prime targets for Robotic Process Automation (RPA).

- Time Delays Between Lanes: If the map includes metrics showing significant wait times at handoff points, automation can be used to trigger the next step instantly. A manufacturing plant might use this to automate quality control notifications between the production line and the QA team.

10. Spaghetti Diagram

A Spaghetti Diagram is one of the most visual and visceral business process mapping techniques, focusing specifically on the physical movement of people, materials, or information within a workspace. Originating from Lean manufacturing principles, it traces the literal path taken to complete a process, resulting in a diagram that often looks like a tangled plate of spaghetti, hence its name. This powerful visualization immediately exposes inefficient layouts, excessive travel, and wasted motion.

Popularized by the Toyota Production System, this technique involves drawing a to-scale layout of a work area and then tracing the actual path of an employee or a part as it moves through the process. The resulting lines quickly reveal opportunities for layout optimization, from reorganizing a manufacturing cell to redesigning a hospital emergency room to minimize the steps nurses have to take. It's a purely physical and observational mapping method.

Key Characteristics & Benefits

- Waste Identification: It excels at highlighting the "waste of motion," one of the seven key wastes (Muda) in Lean methodology. By visualizing unnecessary walking, backtracking, or searching, teams can quantify the impact and prioritize improvements.

- Improved Ergonomics and Safety: Simplifying movement paths not only boosts efficiency but also reduces physical strain on employees, leading to a safer and more ergonomic work environment. This is a common application in warehouse and distribution centers.

- Data-Driven Layout Design: The diagram provides concrete evidence to justify facility reorganizations. For example, a retail store might use it to optimize its layout, placing high-traffic items closer together to improve customer flow and employee restocking efficiency.

Expert Insight: The most effective spaghetti diagrams are created by directly observing and involving the people who do the work. Their participation ensures the map is accurate and builds immediate buy-in for the layout changes that will ultimately make their jobs easier and more productive.

Automation Readiness Indicators

While spaghetti diagrams map physical movement, they can point toward automation opportunities by identifying:

- High-Volume, Repetitive Paths: A dense cluster of lines between two specific points indicates a frequent and predictable movement. This could be a prime candidate for a conveyor belt, an Automated Guided Vehicle (AGV), or a robotic arm.

- Material Transport Inefficiencies: If a significant portion of the "spaghetti" is related to moving materials from storage to a workstation, it signals a need for automated inventory retrieval systems.

- Time-Consuming Travel: When employees spend more time walking than performing value-added tasks, it justifies exploring automation to bring the work to the worker. Analyzing these paths is a key first step to reduce operational costs through smarter facility design.

Top 10 Business Process Mapping Techniques Comparison

| Technique | Implementation complexity | Resource requirements | Expected outcomes | Ideal use cases | Key advantages |

|---|---|---|---|---|---|

| Flowchart Mapping | Low–Medium — simple to create, grows with branching | Minimal: basic drawing tools and stakeholder input | Clear sequential process visualization; bottleneck identification | Simple to moderately complex sequential processes (onboarding, manufacturing steps) | Universally understood; easy to create and modify; minimal training |

| Swimlane Diagram (Cross-Functional) | Medium — added complexity from lanes and handoffs | Cross-functional input, mapping tools, role information | Clear ownership and handoff visualization; dependency discovery | Multi-departmental processes requiring role clarity (claims, order-to-delivery) | Clarifies responsibilities; reveals communication bottlenecks; improves alignment |

| Value Stream Mapping (VSM) | High — detailed metrics and timeline focus | Significant: gemba data collection, training, time for measurement | Identifies waste, quantifies cycle times, roadmap for improvement | Manufacturing/operations focused on waste elimination and lead-time reduction | Highlights value vs waste; quantifies improvements; aligns with lean |

| BPMN (Business Process Model and Notation) | High — steep learning curve for detailed/executable models | Specialized software, training, business+IT collaboration | Executable, scalable models; enables automation and simulation | Complex enterprise processes needing automation and integration | Standards-based; bridges business and technical teams; supports execution |

| Data Flow Diagram (DFD) | Medium — requires system understanding and decomposition | Systems analysts, documentation tools, knowledge of data sources | Clear depiction of data flows, stores, and system boundaries | System design, data requirements analysis, IT implementation | Emphasizes data interactions; useful for compliance and system design |

| Fishbone Diagram (Ishikawa) | Low — simple structure for facilitated sessions | Facilitated team workshops, subject-matter participants | Structured list of potential causes to investigate | Root cause analysis and quality problem-solving | Encourages broad brainstorming; easy to understand and apply |

| Process Activity Mapping | Medium — needs consensus on value definitions and timing | Stakeholder workshops, timing/resource data, simple tools | Categorizes activities by value; identifies non-value steps for elimination | Operational process waste identification (finance, HR, supply chain) | Distinguishes value vs waste; supports data-driven redesign |

| Service Blueprint | High — multi-layer mapping and customer research needed | Customer research, service design expertise, cross-functional input | Holistic service view: customer journey, frontstage/backstage, failure points | Service industry CX design (hotels, healthcare, banking branches) | Aligns processes with customer experience; identifies hidden failure points |

| Deployment Flowchart | Medium–High — combines swimlane visuals with Six Sigma metrics | Six Sigma training, quantitative data, cross-location coordination | Standardized processes across locations; highlights variation sources | Multi-location standardization and Six Sigma improvement projects | Integrates visual mapping with performance data; supports standardization |

| Spaghetti Diagram | Low — simple to draw but needs on‑site observation | Facility access, floor plans, observation or video capture | Visual identification of inefficient physical movement and backtracking | Facility layout optimization and movement waste reduction (warehouses, hospitals) | Immediately reveals travel inefficiencies; simple and highly visual |

Turn Your Process Maps into Automation ROI

You've journeyed through ten distinct and powerful business process mapping techniques, from the foundational simplicity of Flowcharts to the strategic depth of Value Stream Mapping and the technical precision of BPMN. Each method offers a unique lens through which to view your organization's inner workings, revealing hidden inefficiencies, communication gaps, and opportunities for profound transformation. The key takeaway is that no single technique is universally superior; the optimal choice depends entirely on your specific goal, whether it's clarifying roles with a Swimlane Diagram, pinpointing root causes with a Fishbone Diagram, or optimizing physical movement with a Spaghetti Diagram.

Mastering these visual languages is more than an academic exercise. It's the foundational step toward building a more resilient, efficient, and competitive organization. A well-executed process map is not just a static document; it is a dynamic blueprint for action. It transforms abstract operational challenges into a concrete, shared understanding that aligns stakeholders from the C-suite to the front lines. This clarity is the catalyst for meaningful change, enabling teams to make data-driven decisions rather than relying on institutional knowledge or guesswork.

From Blueprint to Bottom-Line Impact

The true power of business process mapping is unlocked when it moves from documentation to implementation. Your maps are the diagnostic tools that identify the prime candidates for optimization and automation. By using techniques like VSM or Process Activity Mapping, you can precisely quantify the time, cost, and resources consumed by manual, repetitive tasks. These are the bottlenecks that drain productivity and stifle growth, and they represent the most fertile ground for intelligent automation.

Once you have identified these high-impact opportunities, the next step is to translate your insights into a tangible return on investment. This involves selecting the right technology stack to execute the improvements your maps have highlighted. To effectively turn your process maps into tangible returns, exploring the landscape of available solutions is crucial. For a comprehensive overview of your options, consider reviewing a guide to the best business process automation tools to find platforms that align with your specific needs.

Key Insight: A process map is not the final product. It is the first, essential step in a continuous cycle of analysis, improvement, and automation that drives measurable business value. Don't let your analysis end with the diagram; use it as the starting point for strategic action.

Activating Your Automation Strategy

The ultimate goal is to create a seamless operational flow where human talent is focused on high-value strategic work, while technology handles the rule-based, repetitive processes. Your process maps serve as the definitive guide for this transition. They provide the detailed specifications needed to design, build, and deploy custom automation solutions that address your unique challenges.

Consider the following actionable steps to bridge the gap between mapping and automation:

- Prioritize with Data: Use the metrics gathered during your mapping (e.g., cycle time from VSM, handoff delays from Swimlanes) to create a priority list of processes for automation. Target the ones that promise the highest ROI in terms of time saved, error reduction, or cost avoidance.

- Develop a Pilot Program: Select a single, well-defined process from your priority list for a pilot automation project. This allows you to demonstrate value quickly, learn from the experience, and build momentum for broader initiatives.

- Engage an Expert Partner: Translating a process map into a robust, AI-driven workflow requires specialized expertise. Partnering with specialists can accelerate development, mitigate risks, and ensure the final solution is scalable, secure, and perfectly aligned with your business objectives.

Ultimately, the diverse array of business process mapping techniques are your tools for discovery. They empower you to see your organization with unprecedented clarity, diagnose its weaknesses, and design its future. By embracing these methods not as a one-time project but as an ongoing discipline, you build a powerful engine for continuous improvement and innovation, ensuring your business is not just surviving, but thriving in an increasingly complex world.

Ready to turn your process insights into a competitive advantage? At Red Brick Labs, we specialize in transforming your process maps into custom AI-powered automation solutions that deliver measurable ROI in weeks, not years. Book a discovery call to see how we can help you build the efficient, scalable operations of the future.