When we talk about AI in supply chain optimization, we’re really talking about using artificial intelligence to predict, analyze, and automate decisions. It's what turns a reactive, fire-fighting supply chain into a proactive, resilient network.

This isn't just a minor tweak. It's a fundamental shift that allows a business to stop just responding to disruptions and start anticipating them. The result? Significant cost savings and much happier customers.

Why AI Is the New Engine for Supply Chain Resilience

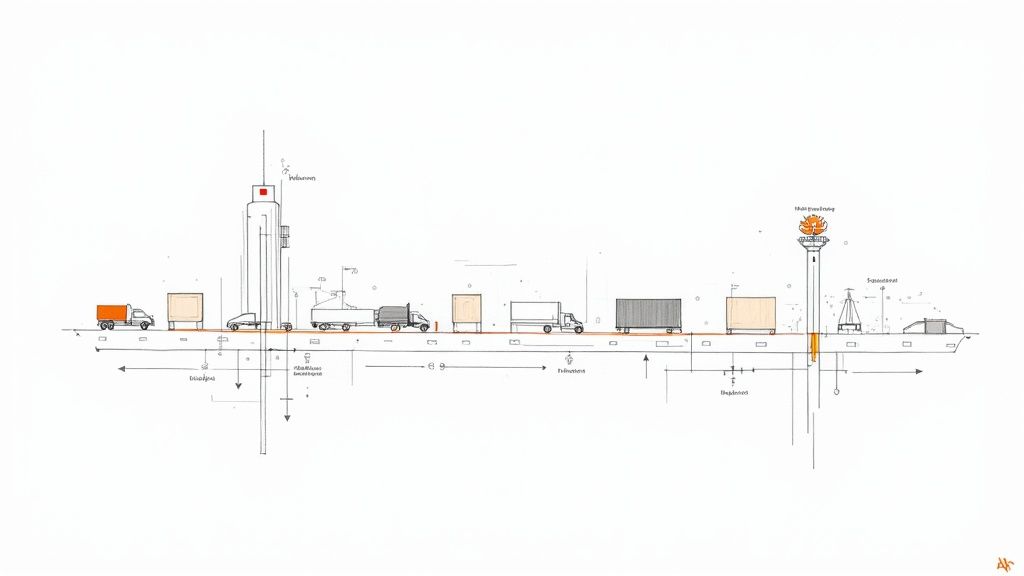

Picture a traditional supply chain as a basic highway map. Managers see a problem—a traffic jam, a closed bridge—and react to it only after it’s already causing delays. This reactive approach leads to costly express shipping fees, bloated safety stock, and blown delivery windows.

Think about it. A sudden port closure or an unexpected spike in demand can create bottlenecks that ripple through the entire system for weeks. You're always one step behind.

AI completely changes the game. It’s like upgrading from that paper map to an intelligent, real-time traffic control center for your entire logistics network. This system becomes the central nervous system, constantly processing massive amounts of data.

Instead of just seeing the traffic jam, the AI predicts it by analyzing weather forecasts, shipping lane congestion, and even social media trends. It can then proactively reroute shipments or adjust inventory levels at nearby warehouses long before a problem ever grinds things to a halt.

Shifting from Reactive to Predictive Management

This is the core of what AI in supply chain optimization really means. It’s about finally moving beyond spreadsheets and gut-feel adjustments to a system that actually learns, adapts, and makes smart recommendations on its own.

This predictive stance is absolutely critical for building resilience in today's volatile global market. To make this work, companies also need to adopt modern supply chain risk management strategies that can harness AI's predictive power.

The benefits here aren't just theoretical; they hit the bottom line directly:

- Reduced Operational Costs: AI helps you slash waste from overstocking, cut fuel consumption with smarter routes, and prevent expensive downtime with predictive maintenance alerts.

- Faster, More Reliable Deliveries: By seeing disruptions before they happen, AI ensures products get where they need to go on time, which is a massive driver for customer loyalty.

- Enhanced Decision-Making: It gives your team the data-driven insights they need, freeing them from tedious analysis so they can focus on bigger strategic problems.

AI isn't just another tool; it's a foundational shift in how supply chains operate. It enables a level of foresight and agility that was previously unattainable, turning potential crises into manageable adjustments.

Ultimately, integrating AI is no longer a futuristic concept—it’s a competitive necessity. This guide will give you a clear roadmap for putting AI to work, showing you how to improve supply chain efficiency and get results you can actually measure.

Core AI Applications Transforming Logistics

![]()

It’s easy to talk about the benefits of AI in the abstract. But where does the rubber actually meet the road? The real value of AI in supply chain optimization becomes clear when you see how it tackles the specific, nagging problems that logistics managers have wrestled with for decades.

These aren’t futuristic concepts from a research lab; they are practical tools delivering measurable results right now. Each one turns a process once dominated by guesswork and spreadsheets into a system driven by data and intelligence.

To understand how AI is changing the game, let's break down the key applications that are solving real-world challenges in the supply chain, from the warehouse floor to the final mile.

AI Applications in Supply Chain Optimization

The following table maps out how specific AI applications directly address long-standing operational headaches and generate tangible business outcomes.

| AI Application | Traditional Challenge | AI-Driven Solution | Key Performance Indicator (KPI) Impact |

|---|---|---|---|

| Demand Forecasting | Relying on historical data, leading to stockouts or overstocking. | Analyzes vast datasets (market trends, weather, social media) to predict demand with high accuracy. | Improves forecast accuracy by 20-30%; reduces lost sales due to stockouts. |

| Inventory Optimization | High carrying costs and inefficient stock distribution across multiple locations. | Calculates optimal inventory levels, reorder points, and placement to meet predicted demand. | Reduces inventory holding costs by 10-25%; increases inventory turnover. |

| Dynamic Routing | Static routes fail to account for real-time disruptions like traffic or weather. | Continuously recalculates the most efficient routes using live data feeds. | Cuts fuel costs and delivery times by 5-15%; improves on-time delivery rates. |

| Predictive Maintenance | Unexpected equipment failures cause costly downtime and production delays. | Uses IoT sensor data to predict machine failures before they happen, enabling proactive repairs. | Reduces unplanned downtime by up to 50%; lowers maintenance costs by 20-40%. |

| Procurement Automation | Manual, time-consuming supplier negotiation and risk management processes. | Analyzes market data and supplier performance to identify optimal purchasing decisions and automate tasks. | Lowers procurement costs by 5-10%; improves supplier reliability and resilience. |

As you can see, each application provides a direct line from a data-driven insight to a bottom-line result. Now, let’s dig a little deeper into how each of these works in practice.

AI-Powered Demand Forecasting: Your Business Weather Report

Traditional demand forecasting often feels like trying to predict this weekend’s weather using last year’s almanac. You’re relying on historical sales data, which is a decent starting point but completely misses the countless external variables that shape what customers buy today. This inevitably leads to the classic warehouse dilemma: tying up cash in overstocked items or losing sales because you ran out of a hot seller.

AI-powered forecasting is more like a sophisticated, real-time meteorological system for your business. It doesn’t just look at past sales; it analyzes a massive universe of data.

- External Data Integration: AI models pull in market trends, competitor pricing, social media chatter, economic reports, and even local weather forecasts.

- Pattern Recognition: Machine learning algorithms are brilliant at spotting subtle connections in all that data—the kind no human team could ever catch—to find the true drivers of demand.

- Self-Correcting Accuracy: Best of all, these systems never stop learning. Every new data point, from a sudden holiday shopping spree to a dip in consumer confidence, helps refine future predictions. They get smarter over time.

The result is a forecast that isn't just a look in the rearview mirror. It’s an intelligent prediction of what’s coming, giving you the power to make much smarter decisions about inventory and production.

Intelligent Inventory Optimization: The Smart Pantry

Think of your entire warehouse network as a giant pantry. Without a smart system, you might end up with too much of one ingredient expiring on the shelf while constantly running out of another. That’s the reality for many businesses—a constant, manual tug-of-war between high holding costs and the risk of stockouts.

Intelligent inventory optimization turns that chaotic pantry into a smart, self-stocking system. It uses AI to maintain the perfect equilibrium of products across every single location.

This system answers the most critical questions with incredible precision:

- What should we order? Based on hyper-accurate demand forecasts.

- When should we order it? By calculating the perfect reorder points to prevent shortages.

- How much do we need? Enough to meet demand without driving up holding costs.

- Where should we keep it? By positioning inventory closer to customers to slash shipping times and costs.

By connecting demand signals directly to inventory levels, AI ensures that the right products are always in the right place at the right time. This dramatically reduces carrying costs and virtually eliminates lost sales due to stockouts.

One multinational retailer, for instance, used this very approach to achieve a 20% reduction in stockouts, which went straight to their top line and boosted customer loyalty.

Dynamic Route Optimization: The GPS on Steroids

Your standard route planning software is static. It calculates the shortest path based on fixed data like road distance and speed limits. But the real world is anything but fixed. A traffic jam, a sudden road closure, a storm, or a last-minute delivery change can make a "perfectly planned" route completely useless.

Dynamic route optimization is like a GPS on steroids, with a real-time AI brain making the calls. It constantly ingests live data streams to make intelligent adjustments on the fly, considering variables that static planners completely ignore, like live traffic feeds, weather alerts, vehicle capacity, and even delivery priority.

In the fast-moving world of global supply chains, AI-powered analytics has become a serious advantage, helping companies slash logistics costs by an impressive 5% to 20%. By digging into sales histories, market shifts, and even weather patterns, AI helps businesses cut waste, position inventory intelligently, and raise their service game. Despite the clear upside, a huge adoption gap exists—77% of professionals have yet to bring AI into their workflow, pointing to a massive opportunity for those ready to move first. You can learn more about where the industry is heading and discover the key supply chain trends for 2025.

This means your routes aren't just the shortest, but the most efficient at that very moment, leading to real savings in fuel costs, fewer late deliveries, and a smaller carbon footprint.

Predictive Maintenance: The Health Tracker for Machinery

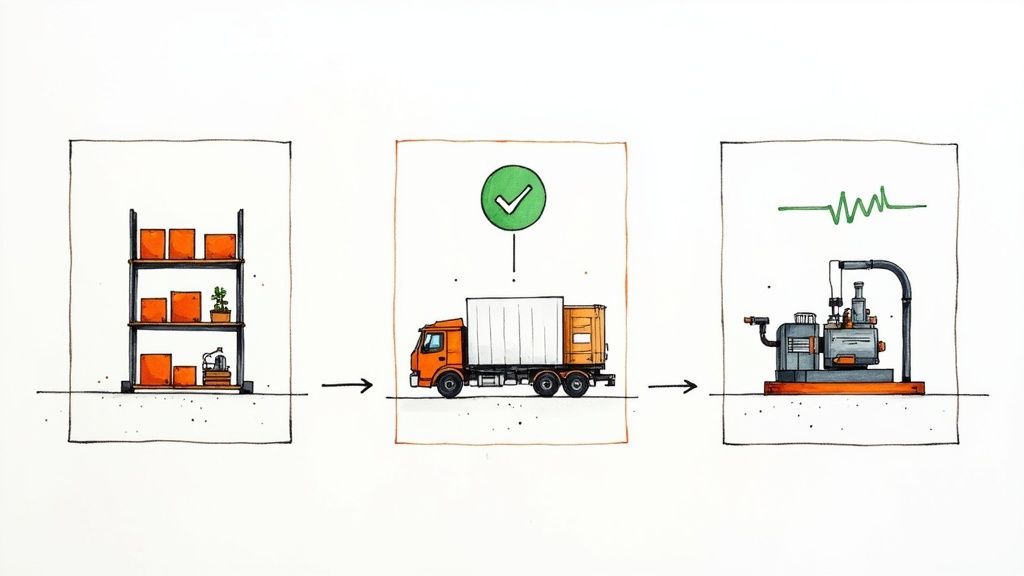

In any busy warehouse or factory, equipment failure is a disaster. A single broken conveyor belt or forklift can bring operations to a grinding halt, causing expensive downtime and throwing production schedules into chaos. The old model of reactive maintenance—fixing things only after they break—is both costly and disruptive.

Predictive maintenance offers a far smarter alternative. Think of it as a health and fitness tracker for your most critical machinery. IoT sensors gather real-time performance data like temperature, vibration, and energy use. AI algorithms then analyze this data, looking for tiny anomalies that signal an impending failure, often weeks before it would happen.

Instead of waiting for a breakdown, the system flags a potential issue and alerts the maintenance team. They can then schedule repairs during planned downtime, when it's least disruptive. This proactive approach all but eliminates unplanned shutdowns, extends the lifespan of your equipment, and significantly cuts maintenance costs.

Automated Procurement: The 24/7 Expert Negotiator

Procurement is loaded with complex, time-consuming work: finding suppliers, negotiating prices, managing contracts. It often runs on manual processes and long-standing relationships, which can mean leaving better, cheaper opportunities on the table.

AI-driven automated procurement functions like an expert negotiator that never sleeps. It continuously scans market data, supplier performance metrics, and commodity price changes to pinpoint the best purchasing opportunities in real time.

This technology can:

- Automate supplier discovery by finding vendors that perfectly match your criteria for cost, quality, and reliability.

- Analyze spending patterns across the organization to spot areas for consolidation and cost savings.

- Monitor supplier risk by keeping an eye on things like financial stability and geopolitical events that could disrupt your supply chain.

By handling the heavy analytical lifting, AI frees up your procurement team to focus on what they do best: building strategic partnerships with suppliers instead of getting buried in administrative tasks. This drives down costs and helps you build a more resilient and agile supplier network.

Building Your Foundation for a Smarter Supply Chain

Jumping into AI in supply chain optimization isn't about flipping a switch; it's about building a solid foundation first. You wouldn't build a skyscraper on soft sand, and the same logic applies here. Before any algorithm can start working its magic, it needs two things: high-quality data and a clear plan for which AI tools to use.

Think of it like preparing a gourmet meal. Your AI models are the master chefs, ready to create something incredible. But even the best chef is useless if the pantry is filled with spoiled or missing ingredients. Your data is those ingredients, flowing from every corner of your operation.

Gathering the Right Ingredients: Your Data Sources

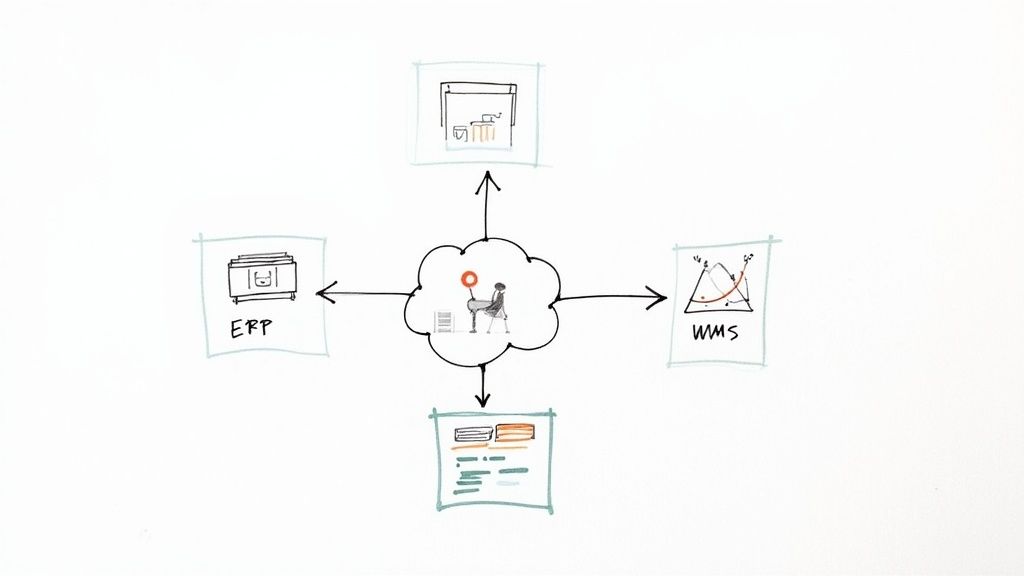

The term "big data" gets thrown around a lot, but for AI, the real focus is on good data. That means your data has to be clean, accessible, and, most importantly, integrated. AI systems get their power by connecting the dots between systems that, in most companies, have never really talked to each other.

Here are the essential data sources you'll need to tap into:

- Enterprise Resource Planning (ERP) Systems: This is your company's central nervous system. It holds all the critical information on orders, financials, and high-level inventory.

- Warehouse Management Systems (WMS): This is your eyes and ears on the warehouse floor, giving you real-time data on stock levels, order picking status, and how much space you have left.

- Transportation Management Systems (TMS): Your TMS is the source for all things logistics. It tracks shipment statuses, carrier performance, and what you’re paying for freight.

- Internet of Things (IoT) Sensors: These are your live-action cameras, providing real-time feeds from trucks, containers, and machinery on everything from location and temperature to performance.

For a truly modern setup, innovations like new tech packaging solutions with IoT labels can turn a simple package into a rich source of live information, feeding your AI the granular data it needs.

To make it all work, these separate streams of data have to be brought together. This is where a unified data architecture—like a data lake or data warehouse—becomes non-negotiable. It acts as a central reservoir where all your supply chain data lives, creating a single source of truth for your AI models to draw from.

Understanding Your AI Toolkit: Key Model Patterns

Once your data house is in order, you need to pick the right "chef" for the job. You don't need to become a data scientist overnight, but a basic grasp of the concepts helps you match the right tool to the right business problem.

The goal of AI here isn’t to be some mysterious black box. It’s about applying specific, understandable model patterns to solve real-world problems, like cutting costs or hitting delivery windows more consistently.

Let's break down a few key AI approaches with some simple logistics analogies.

-

Supervised Learning: Think of this as training a new hire by showing them a huge stack of past examples. You feed the model labeled data—like historical sales figures paired with the actual demand that followed—and it learns to predict what will happen next. This is the workhorse behind most demand forecasting models.

-

Unsupervised Learning: This is like giving an analyst a mountain of data and saying, "Find something interesting in here." This type of AI is brilliant at finding hidden patterns you didn't even know to look for, like segmenting customers into new buying groups or spotting unusual network activity that might signal a looming disruption.

-

Reinforcement Learning: This is the most dynamic approach, like a grandmaster playing a million games of chess at once. The AI agent learns by doing. It takes actions in a simulated version of your supply chain and gets "rewarded" or "penalized" based on the outcome. Over millions of runs, it teaches itself the absolute best strategy for complex challenges like dynamic routing or multi-echelon inventory balancing, constantly adapting to new information to find the optimal path.

A Practical Roadmap to AI Implementation

Bringing AI into your supply chain isn't a massive, all-or-nothing bet. The smartest companies treat it like a strategic campaign, not a technical Hail Mary. They follow a clear, phased approach that builds momentum, proves value at every turn, and turns a huge undertaking into a series of smart, manageable wins.

Think of it less like flipping a switch and more like building a solid foundation. You start small, prove it works, and then expand with confidence. Each phase builds on the success of the last, making sure the entire structure is sound and built for your specific needs.

Phase 1: Discovery and Strategy

First things first: you need a target. Before you even think about vendors or code, you have to find the one business problem where AI will make the biggest, most obvious difference. It’s tempting to try and fix everything at once, but that's a recipe for failure.

Get specific. Ask the tough questions:

- What’s our single biggest headache right now? Is it chronic stockouts? Sky-high freight costs? Unplanned machine downtime?

- If we could solve just one of those problems, which would give us the best financial return or a real edge over the competition?

- Do we actually have the data we need to tackle this?

Once you’ve zeroed in on a clear problem—say, cutting stockouts on your top 20% of SKUs—you define what winning looks like. This means benchmarking your current performance and setting a concrete goal. Something like, "We will reduce stockouts for our key products by 15% within six months."

This is also when you get your leadership on board. A focused business case with a clear ROI is infinitely more powerful than a vague pitch to "do more with AI." For a deeper dive on getting this first step right, check out this guide on how to implement AI in business.

Phase 2: The Pilot Program

With a clear mission, it’s time to prove it can be done. A pilot program is your small-scale, controlled experiment. It’s where you test your idea in the real world, minimize your risk, and show everyone what’s possible.

For that inventory problem, your pilot might mean pointing an AI forecasting model at just one product category or a single warehouse. The goal isn’t to overhaul the entire company overnight. It’s simply to prove, with hard data, that the AI model can do the job better than your current process.

To pull this off, you’ll need a small, dedicated team:

- An Executive Sponsor: Someone in leadership who can champion the project and remove roadblocks.

- Subject Matter Experts: The people on the ground—your supply chain managers—who know the operational realities.

- Data & IT Crew: The folks who can get you the clean data you need to feed the model.

A successful pilot does more than just prove a technology works; it creates internal champions. When your team sees tangible results firsthand, they become the biggest advocates for broader adoption.

This focused trial teaches you invaluable lessons about your data quality, the model's real-world performance, and how this new tool actually fits into people's daily jobs. All of this is crucial for the final step.

Phase 3: Scale and Integrate

Once your pilot has delivered the goods, you're ready to go big. The final phase is all about taking what you learned from your test and rolling the solution out across the wider operation. This is where AI stops being a "project" and becomes part of the furniture—a core piece of how your supply chain runs every day.

But scaling isn't just a technical exercise; it's a people-and-process challenge. You have to train your teams to trust and use the insights the AI provides. Automation is already shaking up logistics, where warehouses using autonomous robots are seeing massive uptime improvements. That's a huge deal, especially when a single supply chain disruption can wipe out nearly half a decade’s worth of profit.

The trick is to roll it out thoughtfully. You might expand your inventory model from one product line to five, then to all of them. This deliberate, step-by-step approach lets you iron out wrinkles as you go, refining the process and ensuring each new expansion is just as successful as the pilot. This is how you transform AI from a shiny object into a true competitive advantage that keeps paying dividends.

Here’s the rewritten section, designed to sound like an experienced human expert.

Sidestepping the Pitfalls & Proving the Payoff

Let's be honest: launching an AI initiative in your supply chain sounds great on paper, but the road is paved with predictable, and entirely avoidable, speed bumps. Too many ambitious AI in supply chain optimization projects don't fail because the tech is bad—they stumble because the foundational work was overlooked.

Getting this right means anticipating the challenges before they become expensive problems. By understanding what trips most companies up, from messy data to skeptical teams, you can build a strategy that delivers real, measurable value right out of the gate.

Navigating the Common Implementation Hurdles

Here's a hard truth: even the most brilliant AI model is completely useless if it’s built on a shaky foundation. Most failures I've seen trace back to a handful of core issues that can kill a project long before it has a chance to prove its worth. Getting ahead of them is half the battle.

- Garbage In, Garbage Out: This is, without a doubt, the #1 project killer. Your AI is only as smart as the data you feed it. If the information from your ERP, WMS, and TMS systems is siloed, riddled with errors, or just plain inconsistent, your AI will spit out unreliable nonsense.

- Vague Business Goals: Starting an AI project with a fuzzy goal like "improve efficiency" is like setting sail without a map. It gets you nowhere. You need a concrete target, something you can actually measure, like "cut inventory holding costs by 15% for our top-selling product line."

- The Human Element: Don't underestimate this one. Your team might see AI as a threat to their jobs or just another "flavor of the month" from corporate. If the people who are supposed to use the tools don't buy in, the most sophisticated system in the world will just gather digital dust. No adoption means zero ROI.

The biggest barrier to AI success isn't technical complexity; it's organizational readiness. A pilot project can fail due to poor data quality or internal resistance just as easily as it can from a flawed algorithm.

To steer clear of these traps, focus on creating a single source of truth for your data. Pick a narrow, high-impact business case for your first project, and bring your operations team into the fold early and often. Their feedback is gold, and their trust is essential.

Introducing the Pitfall Playbook

Thinking through these potential roadblocks from the start can make the difference between a stalled project and a successful rollout. Here’s a quick-glance table to help you prepare.

| Common Pitfall | Potential Impact | Mitigation Strategy |

|---|---|---|

| Poor Data Quality | Inaccurate predictions, flawed recommendations, and a complete lack of trust in the system. | Conduct a thorough data audit before starting. Invest in data cleansing and establish a unified data lake or warehouse to create a "single source of truth." |

| Unclear Objectives | Wasted resources on low-impact problems, inability to measure ROI, and a lack of executive buy-in for future projects. | Define a specific, measurable, achievable, relevant, and time-bound (SMART) goal. Start with a narrow pilot project tied to a clear business pain point. |

| Internal Resistance | Low user adoption, active sabotage of the new system, and a failure to integrate AI insights into daily workflows. | Involve end-users from the very beginning. Communicate transparently about how AI will augment their roles, not replace them. Provide robust training and highlight early wins. |

| "Black Box" Problem | Operations teams distrust and override AI recommendations because they don't understand how the model arrived at its conclusions. | Choose AI models that offer some level of explainability (XAI). Create simple dashboards that visualize the "why" behind the recommendations, not just the "what." |

| Scope Creep | The initial project becomes too large and complex, leading to budget overruns, missed deadlines, and eventual failure to launch. | Keep the scope of the first pilot project tightly controlled. Focus on solving one specific problem well, then build on that success for future phases. |

This isn't an exhaustive list, but it covers the big ones. A little foresight here goes a long way in ensuring your investment pays off.

Measuring What Actually Matters

Once your AI system is up and running, how do you know it's actually working? Success isn't about a flashy dashboard; it's about moving the needle on the metrics that hit your bottom line. Forget vanity metrics—we need to track tangible improvements.

The right Key Performance Indicators (KPIs) will depend on the specific problem you’re solving, but they should always tie back to clear financial or operational wins.

Here are the KPIs that matter most:

-

For Inventory Management:

- Inventory Holding Costs: A direct measure of how much cash you're saving by not overstocking.

- Stockout Rate: The ultimate test of your forecasting. Are you preventing lost sales?

- Inventory Turnover: A higher number here means you’re moving product efficiently instead of letting it sit.

-

For Logistics and Transportation:

- On-Time Delivery Rate: This is your customer satisfaction score and a direct reflection of network reliability.

- Cost Per Shipment/Mile: Tracks the real-dollar savings from smarter routing and carrier choices.

- Fuel Consumption: A crucial metric for both your budget and your sustainability targets.

By tracking these KPIs before and after your AI goes live, you create a clear, data-driven story of your return on investment (ROI). This not only proves the value of your first project but also builds a rock-solid business case for expanding AI in supply chain optimization across your entire operation.

Real World Examples of AI in Action

Theory is one thing, but seeing how AI actually performs in the real world is where the value becomes crystal clear. Companies across the board are moving past the "what if" stage and are now embedding AI into their core operations to fix stubborn, expensive problems. These aren't just small tweaks; we're talking about major leaps in performance.

Let's look at how this plays out on the ground. These stories show just how powerful a well-aimed AI solution can be.

Nailing Inventory to Stop Stockouts

A mid-sized distributor was stuck in the classic inventory trap. They had multiple warehouses, but it was a constant battle between costly overstock in one location and frustrating stockouts in another. Trying to balance inventory levels felt like a guessing game, and it was costing them sales and forcing expensive emergency shipments between their own facilities.

They brought in an AI-powered inventory optimization system, which finally gave them a complete view of their operations. The system chewed through historical sales data, supplier lead times, and local demand trends to predict exactly which products needed to be where.

The results were almost immediate.

- They saw a 30% reduction in stockouts on their hottest items, which directly translated to more revenue.

- The number of last-minute transfers between warehouses dropped dramatically, cutting a huge chunk out of their logistics budget.

- Inventory started moving faster, freeing up cash that used to be locked in slow-moving products.

The AI didn't just manage stock levels; it turned their inventory from a reactive headache into a proactive, demand-sensing asset. It made sure the right products were in the right place, ready for the customer.

Slashing Fuel Costs with Smarter Routing

For a large logistics company, fuel is always one of the biggest line items on the expense report. Their old method of using static, pre-planned routes just couldn't keep up with reality. A single traffic jam, unexpected road closure, or last-minute delivery change would throw everything off, leading to wasted fuel and unhappy customers.

They switched to a dynamic routing platform that used AI to analyze live data from the field. In real time, the system constantly recalculated the most efficient path for every single truck in the fleet. If an accident blocked a highway, drivers were automatically rerouted before they even hit the traffic.

This shift resulted in a 15% decrease in overall fuel costs—a massive number for a company of their size. Even better, their on-time delivery rates shot up, which did wonders for their customer relationships and gave them a serious edge over the competition. It's just one of the many compelling supply chain case studies proving that AI delivers a real, measurable impact on the bottom line.

Your Questions on AI in Supply Chain Answered

When I talk to supply chain leaders, the same practical questions always come up. It's one thing to talk about AI in theory, but it’s another to figure out how it fits into your actual operations. Let’s tackle the big ones.

How Can a Mid-Sized Company Start with AI Without a Massive Budget?

This is the most common question, and the answer is simpler than you think: start small and stay focused.

Forget about trying to overhaul your entire supply chain at once. That’s a recipe for a blown budget and a stalled project. Instead, pick one specific, high-impact problem. Think about optimizing a single, costly delivery route or, even better, improving the demand forecast for just your top 10% of SKUs.

The key is to skip the multi-year, custom-built-from-scratch projects. Look at subscription-based AI platforms with pre-built models. A targeted pilot project can show a clear return on investment in months, not years, giving you a rock-solid business case to get more buy-in for the next phase.

What Kind of Data Is Absolutely Essential to Get Started?

You don't need "big data"—you need the right data. The data you need is always tied directly to the problem you’re trying to solve. Don't let anyone tell you otherwise.

- For Demand Forecasting: You'll want at least two years of clean, historical sales data. Anything less, and the model won't have enough history to spot meaningful patterns.

- For Route Optimization: This is more straightforward. You need delivery locations (the more precise, the better), vehicle capacity, and maybe access to real-time traffic data if you can get it.

The focus here is all about quality over quantity. A clean, consistent dataset for one specific use case is infinitely more valuable than a mountain of messy, incomplete data.

AI is here to give your team superpowers, not replace them. It handles the brutal, large-scale data crunching that humans just can't do, freeing your people to be more strategic.

Will AI Replace People on Our Supply Chain Team?

This concern comes up a lot, but it’s based on a misunderstanding of what AI actually does in this context. The goal isn't replacement; it's empowerment.

AI is a pattern-finding machine. It can sift through millions of data points to spot a subtle shift in demand or calculate thousands of route permutations in seconds—tasks that are simply impossible for a human brain.

This automation of heavy analytical work frees your team from staring at spreadsheets all day. They can now focus on the things that require a human touch: negotiating with a difficult supplier, creatively solving a sudden shipping crisis, or building stronger relationships with key customers. Think of AI as a tool that finally lets your best people do their best work.

Ready to unlock efficiency in your operations? The team at Red Brick Labs designs and builds custom AI automation to eliminate manual processes and deliver measurable ROI. Learn how we can help you scale smarter.